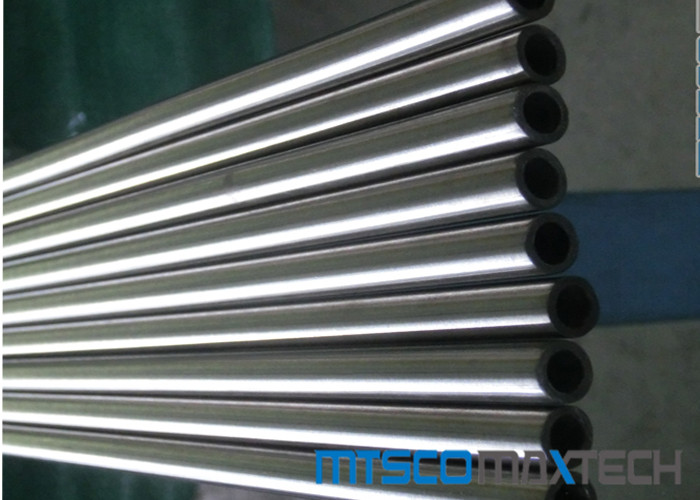

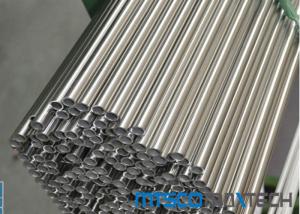

18SWG TP309S / 310S Stainless Steel Precision Tube, ASTM A213 Seamless Tube

SSBA29

Price: From $7000-10000USD/TON

Material: 309/309S/309H, 1.4833; 310/310S/310H,1.4845;

Get Quote

18SWG TP309S / 310S Stainless Steel Precision Tube, ASTM A213 Seamless Tube

MTSCO has the most advanced technology — The floating plug drawing technology which are used in Korea , and equipped with the most environmentally process — Bright annealing process . So our bright annealed precision tube produce technology make us can produce 300 tons high precision tubes every months .

Product Description

| Outer Diameter | 3.18-101.6mm |

| Wall Thickness | 0.5-20mm |

| NPS | 1/8"-24" |

| Schedule | 5/5S,10/10S,20/20S,40/40S,80/80S,120/120S,160/160S |

| Material Grade | 304/304L/316/316L/321/309S/310S, etc |

| Standard | ASTM A269, ASTM A312, etc |

| Application | used in Fluid and Gas Transport, Structure and Machining,etc |

| Certificates | ISO9001:2008, PED, BV |

| Process Method | Cold Drawn/ Cold Rolled |

| Surface Finish | Annealed/ Polished |

| Package | Woven bag for each piece, then packed in seaworthy wooden cases |

| Delivery Time | 20-60 Days after receiving the deposit (Normally according to the order quantity) |

| Price Item | FOB, CIF or as negotiation |

| Payment | T/T(30% in advance, 70% against the BL Copy) or as negotiation |

| Quality Requirement | Mill Test Certificate will be supplied with shipment, Third Part Inspection is acceptable |

| Main Market | Europe, Middle East, Southeast Asia, South America, etc |

ASTM A213 / A213M Chemical Composition :

| Elements | TP310S(wt%) S31008 |

| (C) Carbon, max : | 0.08 |

| (Mn) Manganese, max : | 2 |

| (P) Phosphorus, max : | 0.045 |

| (S) Sulfur, max : | 0.03 |

| (Si) Silicon, max : | 1 |

| (Ni) Nickel : | 19.0 - 22.0 |

| (Cr) Chromium : | 24.0 - 26.0 |

| (Mo) Molybdenum : | - |

| (Fe) Iron : | - |

| (Cu) Copper : | - |

| (N) Nitrogen : | - |

Specification :

Size | OD : 4.76 - 25.4mm |

| WT : 0.71 - 2.11mm | |

| Length : >1000Meters | |

| 4.76 * 0.71mm / 4.76 * 0.89mm / 4.76 * 1.24mm | |

| 6 * 1mm / 6 * 1.5mm | |

| 6.35 * 0.71mm / 6.35 * 0.89mm / 6.35 * 1.24mm / 6.35 * 1.65mm | |

| 7.94 * 0.71mm / 7.94 * 0.89mm / 7.94 * 1.24mm / 7.94 * 1.65mm | |

| 9.53 * 0.71mm / 9.53 * 0.89mm / 9.53 * 1.24mm / 9.43 * 1.65mm | |

| 10 * 1mm / 10 * 1.5mm | |

| 12 * 1mm / 12 * 1.5mm / 12 * 2mm | |

| 12.7 * 0.71mm / 12.7 * 0.89mm / 12.7 * 1.24mm / 12.7 * 1.65mm / 12.7 * 2.11mm | |

| 14 * 1mm / 14 * 1.5mm / 14 * 2mm | |

| 15.88 * 0.89mm / 15.88 * 1.24mm / 15.88 * 1.65mm / 15.88 * 2.11mm | |

| 16 * 1mm / 16 * 1.5mm / 16 * 2mm | |

| 19.05 * 0.89mm / 19.05 * 1.24mm / 19.05 * 1.65mm / 19.05 * 2.11mm | |

| 25.4 * 0.89mm / 25.4 * 1.24mm / 25.4 * 1.65mm / 25.4 * 2.11mm |

VIP SERVICE

VR (Virtual) Mill Introduction

Professional Remote Technical Guidanceion

Accept Third-party Inspection

Door to Door Shipment

Get QuoteRelated Products: Seamless Tube: Bright Annealed Polished Tube

ASTM A269 / ASTM A213 TP309S / 310S Stainless Steel Seamless Instrument Tube For Transportation

MTSCO instrument products are made with high quality raw material. Advanced manufacture equipments and the exquisite craft, technology, characteristic of high precise size, good quality surface, stable performace, especially for the reliable durable performance under high temperature. It is widely a......

Alloy C276/UNS N10276 Nickel Alloy Seamless Pipe/Tube, ASTM B619 / ASME SB619

1. Material Grade: UNS N10276, UNS N10001, UNS N10665, UNS N10675, UNS N06022, N08800, N08825, N04400; etc 2. Outer Diameter: 3.18mm-101.6mm Wall Thickness: 0.5mm-20mm 3. Length: Normally fixed length 6m, can as per customer’s requirement 4. Standard: ASTM B169; ASTM B167; ASTM B444; ASTM ......

Instrument tubing, Hydraulic tubing

The coiled tubing is emerging trends for tubular materials sector. Coiled tubing provides additional perforating capability and flexibility over other conveyance systems. The rigidity and strength of coiled tubing allows greater tensile and compressive force endurance, a major operational advantage ......Control line tubing in oil and Gas Well

Chemical Assurance All the mother pipes will do 100% PMI to ensure we put right materials, and do again after finished to ensure we produce the right materials. This is the way we ensure the chemical quality. Dimension Assurance All the finished pipes will do hydraulic test, dimension test, s......Get Quote

*Your email address will not be published. Required fields are marked.

English

English 中 文

中 文 Español

Español Português

Português Deutsch

Deutsch Türk

Türk Pусский

Pусский عربي

عربي 한국인

한국인 日本語

日本語