Alloy 800, UNS N08800, Nickel Alloy Steel Pipe/Tube, Flanges, Fittings

Alloy 800 (UNS N08800) | |||||||||

Summary | A nickel-chromium alloy with good strength and excellent resistance to oxidation and carburization in high-temperature atmospheres. It also resists corrosion by many aqueous environments. The alloy maintains a stable, austenitic structure during prolonged exposure to high temperatures. Used for process piping, heat exchangers, carburizing equipment, heatingelement sheathing, and nuclear steam-generator tubing. | ||||||||

Standard Product Forms | Pipe, tube, sheet, strip, plate, round bar, flat bar, forging stock, hexagon and wire. | ||||||||

Chemical Composition Wt,% |

| Min | Max. |

| Min. | Max. |

| Min. | Max. |

Ni | 30.0 | 35.0 | Cu |

| 0.75 | C |

| 0.1 | |

Cr | 19.0 | 23.0 | Co |

|

| Si |

| 1.0 | |

Fe | 39.5 |

| Al | 0.15 | 0.6 | P |

|

| |

Mo |

|

| Ti | 0.15 | 0.6 | S |

| 0.015 | |

Nb |

|

| Mn |

| 1.5 | N |

|

| |

Physical Constants | Density,g/ | ||||||||

Melting Range,℃ 1357-1385 | |||||||||

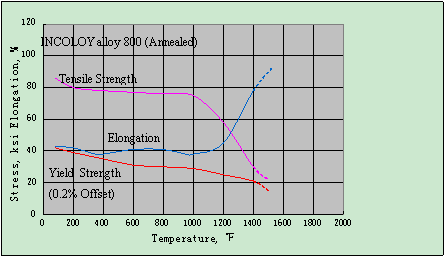

Typical Mechanical Properties | (Annealed) (1000h) Rupture Strength (1000h) ksi Mpa 1000℉/540℃ 48 360 1100℉/595℃ 32 160 1200℉/650℃ 21 50 1300℉/705℃ 11 18 | ||||||||

|

Microstructure

Alloy 800 is an austenitic, solid-solution alloy and has a face-cetered-cubic structure. Titanium nitrides, titanium carbides, and chromium carbides normally appear in the alloy's microstructure.

Characters

Alloy 800H is characterized by:

Good creep-rupture properties at temperatures above 600℃(1110℃) without loss of ductility during long-term use at temperatures below 700℃(1290℉), due to limitation of (Ti+Al) content to max. 0.7%;

Good resistance to reducing, oxidizing and nitriding atmospheres and to atmospheres which alternate between reducing and oxidizing condition;

Metallurgical stability in long-term application at high temperatures.

Alloy 800HT is characterized by:

Excellent creep strength at temperature above 700℃. However, for application where frequent excursions lower than 700℃ during service cannot be excluded or parts of the material are permanently exposed to a temperature below 700℃, the use of Alloy 800H is recommended.

Good resistance to reducing, oxidizing and nitriding atmospheres and to atmospheres which alternate between reducing and oxidizing condition;

Metallurgical stability in long-term application at high temperatures.

Corrosion Resistance

Alloy 800, like many austenitic stainless steels, can be sensitized, or made susceptible to intergranular attack in some aggressive media, by exposure to the temperature range of 1000 to 1400℉(540-760℃).

Application

For services below 600℃ the use of soft annealed Incoloy 800 is suggested. Alloy 800 has aoolication in furnace components and equipment, petrochemical furnace cracker tubes, pigtails and headers, and sheathing for electrical heating elements.

English

English 中 文

中 文 Español

Español Português

Português Deutsch

Deutsch Türk

Türk Pусский

Pусский عربي

عربي 한국인

한국인 日本語

日本語