A403 304/304L 316/316L Stainless Steel Stub End Supplier MTSCO

Material: 304, 1.4301, X5CrNi18-10; 304H, S30415, 1.4948, S30409; 304L, 1.4306, S30403, 1.4307; 316L, 1.4401, 1.4404, 1.4435; 316Ti, S31615, 1.4571, S31635;

Get Quote

A403 304/304L or 316/316L Stainless Steel Stub End

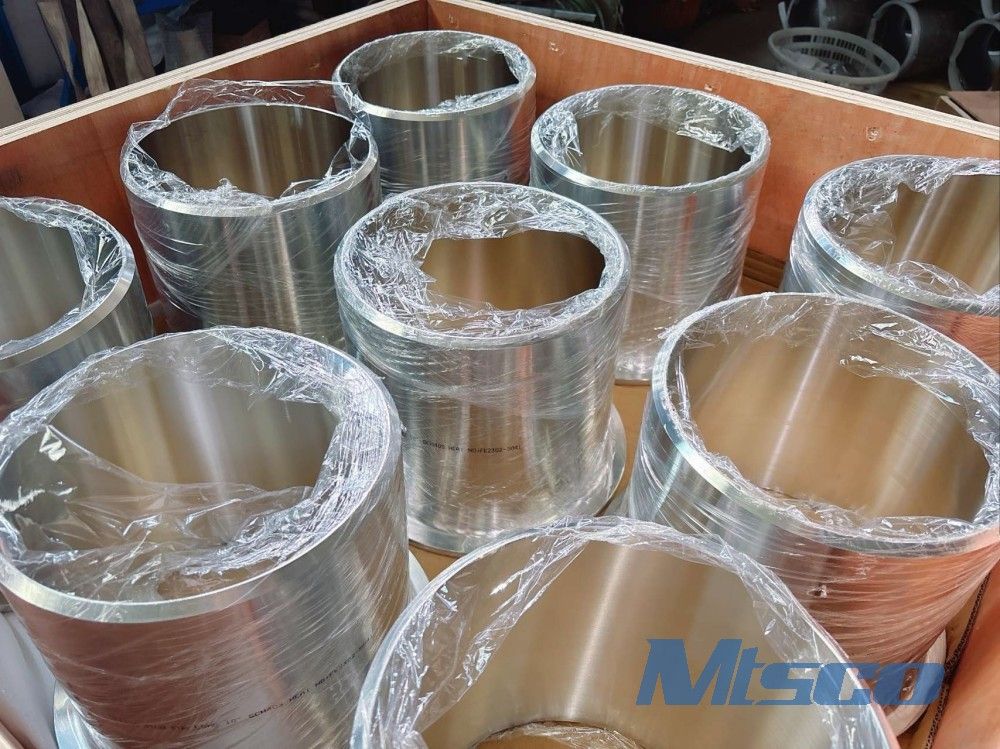

Stainless Steel Stub End is a high - quality product. It is made of 304, 304L, 316, or 316L stainless steel, known for its excellent corrosion resistance and durability. This stub end is designed to be used in piping systems, providing a reliable connection point. The A403 standard ensures its high - level quality and performance. It can withstand various working conditions, including high - pressure and high - temperature environments. Suitable for a wide range of industries such as chemical, food processing, and oil and gas, this stub end is an ideal choice for those seeking long - lasting and efficient piping solutions.

Commodity | Concentric Reducer & Eccentric Reducer , Reducing Tee & Equal Tee, Elbow 45° , 90° , 180° , Cross , Cap , Stub End, etc |

Process Method | Cold Forming |

Grade | TP304/L, TP316/L, S31254, S32205, S32750, Alloy 600/601/625/825/C276/C22... |

Standards | ASTM A403 , A815, B366, EN 10253-4... |

Size Range | OD: ≤2000mm; ≤DN2000; ≤80'' |

Tolerances | according to the specification or customer’s request and drawings |

Applications | oil & gas industry , chemical industry , electric power , boiler and heat exchanger , machinery , metallurgy , sanitary construction etc . |

Production advantages of MTSCO stub end

-Since 2010, MTSCO have held a controlling stake in Hongdi Pipe Industry through cooperation, obtaining ISO/PED/CRN/TS certifications and achieving a vertically integrated supply chain.

-Precision manufacturing is carried out using CNC lathes, 1000-ton hydraulic presses, and automated laser cutting systems.

-Our raw materials come from large factories such as Baosteel, TSINGSHAN, Yongxin... Each batch of raw materials requires MTC and PMI to ensure the quality of the raw materials. After the raw materials arrive, we conduct inspections such as PMI again to ensure they meet the requirements.

-Digital documents at each production stage supervised by factory engineers enable full-process traceability.

-Mandatory 100% pre-shipment inspections are carried out, including dimensional checks, non-destructive testing (ultrasonic testing/radiographic testing), and mechanical property testing.

Project /Facility name | Country | End user/EPC | Material | Products | Qty(KGS) | Year |

Arrow Train 4 | Canada | PCL | 304/304L | 54'' PIPES/FITTINGS | 6,100 | 2024 |

Edmonton Net Zero Hydrogen Energy Complex | Canada | AIR PRODUCTS | N04400, S31803, SS321H, SS316L, SS304L | WELDED PIPE/PIPE/FITTINGS | 350,000 | 2024 |

SOREK II DESALINATION PLANT | ISRAEL | IDE Technogles/BUTTING | S32750, S31254, SS316L | PIPE/FITTING/PLATE | 70,000 | 2024 |

FPSO P80/P83 | Brazil | Petrobras | S32750 | Fitting and Flange 1''-26'' | 700,000 | 2024 |

Shell Nigeria | Nigeria | Shell | S32750 | PIPE/FITTINGS/FLANGE | 18,000 | 2024 |

Performance Advantages of A403 Stainless Steel Stub End

The A403 Stainless Steel Stub End is manufactured in accordance with ASTM A403 standard and is suitable for high-pressure and high-temperature piping systems.

304/304L austenitic stainless steel contains 18% chromium and 8% nickel, and has excellent resistance to oxidation acid corrosion. The low carbon content of L effectively inhibits the precipitation of carbides in the heat-affected zone of welding and reduces the risk of intergranular corrosion.

316/316L stainless steel has an additional 2 - 3% molybdenum element added, which can significantly improve the resistance to chloride stress corrosion and pitting corrosion, and is suitable for marine environments.

Both materials are solution heat treated to ensure a uniform grain structure, with a yield strength of ≥170MPa and an elongation rate of ≥35%, meeting the dimensional tolerance requirements of ASME B16.9.

Application areas of 304/316 Stub End:

The A403 304/304L and 316/316L Stub Ends play a crucial role in industrial piping systems that require corrosion resistance and structural integrity. The Stub Ends are manufactured using a precision cold forming process, with an inner wall surface finish of Ra ≤ 3.2μm. Chemical processing plants: Used for the transportation of acidic and alkaline fluids.

Oil and gas pipelines: Used for the transportation of high-pressure hydrocarbons.

Water treatment facilities: Used for the treatment of chlorinated media.

Food processing equipment: Made of austenitic stainless steel, which can meet its hygienic standard requirements. The equipment has a smooth surface and does not undergo chemical reactions. They can also be used in pharmaceutical production systems (where sterilizable connection components are required) and marine applications exposed to seawater environments.

These pipe fittings are compatible with ASTM B16.9 flange joints and can maintain leak-free connections in thermal expansion systems and power generation cooling loops. There are dual-grade materials available (304/L is suitable for general corrosion environments, and 316/L is suitable for chloride-resistant environments). They are applicable to refinery pipelines, liquefied natural gas receiving terminal infrastructure, and petrochemical processing units and can operate in the temperature range of -425°F to 1650°F.

VIP SERVICE

VR (Virtual) Mill Introduction

Professional Remote Technical Guidanceion

Accept Third-party Inspection

Door to Door Shipment

Get QuoteRelated Products: Pipe Fittings: Butt Welded Pipe Fittings

ASTM A815 / ASME SA815 S32750 / SAF 2507 Duplex Steel 90 Degree Elbow Pipe Fitting For Connection

MTSCO is a leading manufacturer who is specialized in stainless steel seamless pipes , bright annealed tubes , seamless coiled tubing etc . In order to facilitate customers , we have pipe fittings and flanges too . MTSCO has the most advanced producing and testing equipment . We can totally satisfy ......

ASTM A182 Stainless Steel Reducer Pipe Fitting For Connection

MTSCO is a leading manufacturer who is specialized in stainless steel seamless pipes , bright annealed tubes , seamless coiled tubing etc . In order to facilitate customers , we have pipe fittings and flanges too . MTSCO has the most advanced producing and testing equipment . We can totally satisfy ......

WP310s / 309s Stainless Steel Concentric & Eccentric Reducer Pipe Fitting

MTSCO is a leading manufacturer who is specialized in stainless steel seamless pipes , bright annealed tubes , seamless coiled tubing etc . In order to facilitate customers , we have pipe fittings and flanges too . MTSCO has the most advanced producing and testing equipment . We can totally satisfy ......

English

English 中 文

中 文 Español

Español Português

Português Deutsch

Deutsch Türk

Türk Pусский

Pусский عربي

عربي 한국인

한국인 日本語

日本語