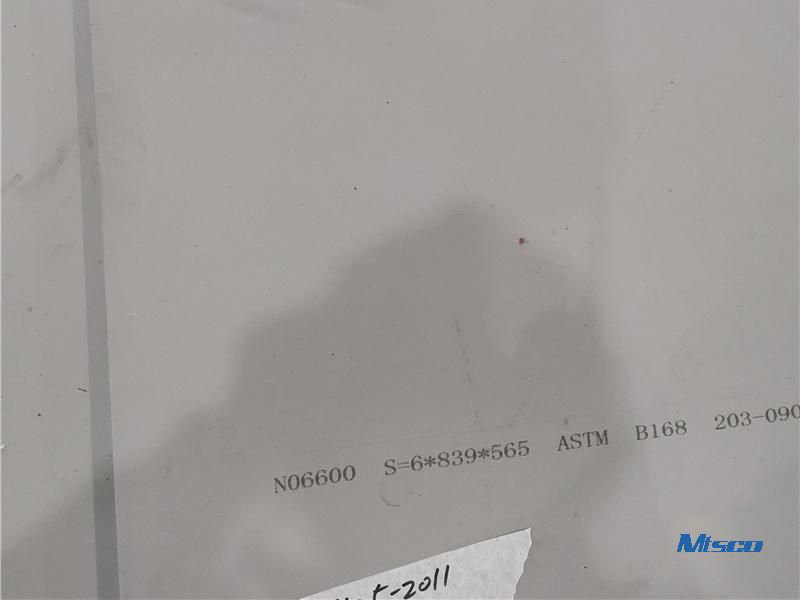

Alloy C276/601/625/825 Nickel Alloy Sheet/Bar/Strip With High Quality

SSNAT36

Material: Alloy 825, UNSN08825, 2.4858; Alloy 625, UNSN06625; Alloy C-276,UNSN10276,2.4819;

Get Quote

Alloy C276/601/625/825 Nickel Alloy Sheet/Bar/Strip With High Quality

1. Grade :Alloy C276/N10276, UNS N06455, UNS N10001, UNS N10665, UNS N10675, UNS N06022, N08800, N08825, N04400; etc

2 . Length : As customer's requirement

3 . Standard : ASTM B333; ASTM B575; ASTM B168; ASTM B443; ASTM B670 etc.

4. Technology : Cold Drawn / Cold Rolled

Product Parameters

| Sheet | Plate | Strip | |

| Width | <1200mm | <3000mm | <200mm |

| Length | As customer's requirement | As customer's requirement | As customer's requirement |

| Thickness | <1mm | <1mm | <0.1mm |

Chemical composition

| % | Ni | Cr | Mo | Fe | W | Co | C | Mn | Si | P | S | V |

| min | balance | 20.0 | 12.5 | 2.0 | 2.5 | |||||||

| max | 22.5 | 14.5 | 6.0 | 3.5 | 2.5 | 0.015 | 0.50 | 0.08 | 0.020 | 0.020 | 0.35 |

Physical properties

| Density | 8.69 g/cm3 |

| Melting range | 1325-1370℃ |

Features: Alloy C276 / UNS N10276 has excellent resistance to localized corrosion, stress corrosion cracking, and to both oxidizing and reducing media, thus making it suitable for a wide variety of chemical process environments, including ferric and cupric chlorides, hot contaminated media (organic and inorganic), formic and acetic acids, seawater and brine solutions. It is one of the few materials that withstands the corrosive effects of wet chlorine gas, hypochlorite and chlorine dioxide.

Applications: Chemical processing, waste treatment, pollution control, pulp and paper production, and marine engineering.

Features: Alloy 625 has excellent strength at temperatures up to 816℃. At higher temperatures, its strength is generally lower than that of other solid solution strengthened alloys. Alloy 625 has good oxidation resistance at temperatures up to 980℃ and shows good resistance to aqueous corrosion, but is relatively moderate compared to other more capable corrosion resistant alloys.

VIP SERVICE

VR (Virtual) Mill Introduction

Professional Remote Technical Guidanceion

Accept Third-party Inspection

Door to Door Shipment

Get QuoteRelated Products: Flanges: SW TH PL LJ Flanges

PN20 - PN420 F316L Stainless Steel Welding Neck/ Slip on/ Blind Flange

PN20 to PN420 indicates the nominal pressure range of the flanges in bar, covering pressure levels from 20 bar to 420 bar, which can meet the pressure requirements under different working conditions.F316L stainless steel is a kind of austenitic stainless steel with high molybdenum content, which is ......

Monel 400 Sheet, UNS N04400 Nickel Alloy 400 Sheet/Plate

The Properties and Applications of Nickel Alloy 400: In terms of features, Monel 400 stands out for its outstanding resistance to corrosion from various reducing media, including sulfuric and hydrochloric acids. Its corrosion resistance to oxidizing media exceeds that of higher copper alloys. Mon......

ASME / ANSI B16.5 PN250 F53 / S32750 Duplex Steel Socket Welding Flange

1. Material Grade: S32205, S31803, S32304, S32750, F51, F53, 2205, 2507 etc 2. Size: 1/2 to 48 Sch 5S to XXS 3. Standard: ASTM A403, ASTM A182 etc . 4. Process Method: Forged / Casting 1 . Commodity : Welding Neck , Blind , Slip On , Lap Joint , Socket Weld , Threaded , Spectacle Blind , ......

English

English 中 文

中 文 Español

Español Português

Português Deutsch

Deutsch Türk

Türk Pусский

Pусский عربي

عربي 한국인

한국인 日本語

日本語