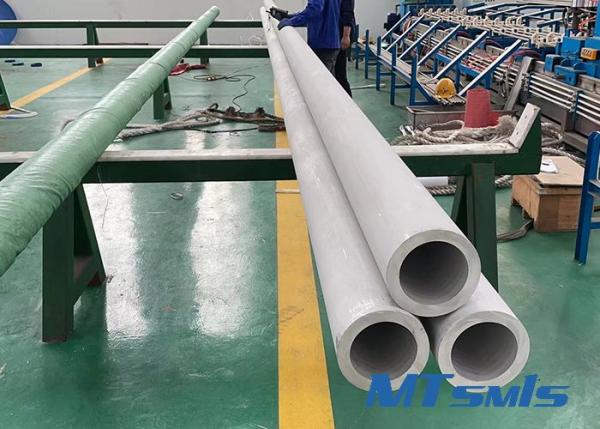

ASTM A312 TP304/304L Stainless Steel Seamless Industrial Pipe

SSAPP15

Price: From $2900-3800USD/TON

Material: 304, 1.4301, X5CrNi18-10; 304H, S30415, 1.4948, S30409; 304L, 1.4306, S30403, 1.4307;

Get Quote

ASTM A312 Pipe

ASTM A312 Standard Specification for Seamless, Welded, and Heavily Cold Worked Austenitic Stainless Steel Pipe, ASTM A312 Pipe is the general use for high temperature service and general corrosive service. It covers diameters from 1/8” to 30” and thickness from SCH 10S to SCH 80S. Common use material grades are TP304/304L, TP316/316L.

ASTM A312 pipe manufacturing types (Including hot finished or cold finished):

ASTM A312 Seamless Pipe (SMLS)

Stainless steel seamless pipe that manufactured in any process that can not be involved in the welding process. Seamless Pipe should be made from stainless steel billet in hot rolling or cold drawn, no any welding process during manufacturing, seamless pipe has better pressure to withstand, annealing solution and pickling finishing condition, applied for high temperature and corrosion environment.

ASTM A312 Welded Pipe (WLD)

Welded pipe that manufactured by an automatic welding process that does not add filler metal during welding, made from stainless steel strip or plate, both single welding and double welding for option, smail diameter and arge diameter are available, annealing pickling finish.

Heavily Cold-Worked Pipe (HCW Pipe)

HCW Pipe shall be made by applying cold working of not less than 35 % reduction in thickness of both wall and weld to a welded pipe prior to the final anneal. No filler shall be used in making the weld. Prior to cold working, the weld shall be 100 % radiographically inspected.

Welded and HCW pipe: Welded pipe and HCW pipe of 14 and smaller than NPS 14 shall have a single longitudinal weld. After approval by the purchaser, the welded pipe and HCW pipe with an NPS greater than NPS 14 shall have a single longitudinal weld or shall be manufactured by forming and welding two longitudinal sections of flat stock. So each welds are to be tested, inspected, inspected or treated.

Heat Treatment

All pipe shall be furnished in the heat-treated condition in accordance with the required heat treating temperature and cooling requirements, pipes shall be individually quenched in water or rapidly cooled by other means (direct quenched).

ASTM A312 pipe shall be free from oxide scale and contaminated iron filings. If the steel pipe is brightly annealed, and pickling, blasting or surface finishing may not be mandatory. The purchaser can request that the finished pipe shall do passivating treatment.

Industrial Pipe, High Strength Steel Pipe

Factors such as material, specification and connection method of industrial pipes will affect their performance and safety, so they need to be selected and designed.

Industrial piping is a kind of industrial facility used to transport various fluids (such as water, oil, gas, steam, etc.), which has a wide range of applications in petroleum, chemical, electric power, metallurgy, shipbuilding and other industries. Factors such as material, specification and connection method of industrial pipes will affect their performance and safety, so they need to be selected and designed according to different working conditions and requirements. High-strength steel pipe is a high-quality industrial piping material, which has important applications in the field of industrial piping.

High-strength steel pipe is used in the petroleum industry, such as drilling pipe, casing, oil pipe, oil pipeline, etc.; chemical industry, can be used as the chemical process of the reactor pipe, heat exchanger pipe, storage tank pipe, etc.; electric power industry, such as boiler pipe, turbine pipe, condenser pipe, etc.; metallurgical industry, such as smelting furnace pipe, rolling mill pipe, casting machine pipe, etc.

High-strength steel pipe has the characteristics of high strength, high toughness, high corrosion resistance, high wear resistance and so on.

ASTM A312 TP304 / 304L Stainless Steel Annealed & Pickled Seamless Industrial Pipe

Chemical Composition

| C(max) | Si(max) | Mn(max) | P(max) | S(max) | Cr | Ni | Mo | Ti | |

| TP304/1.4301 | 0.080 | 1.00 | 2.00 | 0.045 | 0.030 | 18.0-20.0 | 8.0-10.5 | ||

| TP304L/1.4307 | 0.035 | 1.00 | 2.00 | 0.045 | 0.030 | 18.0-20.0 | 8.0-12.0 | ||

| TP304H/1.4948 | 0.04-0.10 | 1.00 | 2.00 | 0.045 | 0.030 | 18.0-20.0 | 8.0-12.0 | ||

| TP316/1.4401 | 0.080 | 1.00 | 2.00 | 0.045 | 0.030 | 16.0-18.0 | 11.0-14.0 | 2.0-3.0 | |

| TP316L/1.4404 | 0.035 | 1.00 | 2.00 | 0.045 | 0.030 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 | |

| TP316Ti/1.4571 | 0.080 | 1.00 | 2.00 | 0.045 | 0.030 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 | 0.7>5x(C+N) |

| TP321/1.4541 | 0.080 | 1.00 | 2.00 | 0.045 | 0.030 | 17.0-19.0 | 9.0-12.0 | 0.7>5x(C+N) | |

| TP317L/1.4449 | 0.080 | 1.00 | 2.00 | 0.045 | 0.030 | 18.0-20.0 | 11.0-14.0 | 3.0-4.0 | |

| TP347H/1.4912 | 0.04-0.10 | 1.00 | 2.00 | 0.045 | 0.030 | 17.0-19.0 | 9.0-13.0 | ||

| TP309S/1.4833 | 0.080 | 1.00 | 2.00 | 0.045 | 0.030 | 22.0-24.0 | 12.0-15.0 | 0.75 | |

| TP310S/1.4845 | 0.080 | 1.00 | 2.00 | 0.045 | 0.030 | 24.0-26.0 | 19.0-22.0 | 0.75 |

Application |

| a) For fluid & gas transport |

b) Structure & machining etc |

Advantages |

| a) Advanced technology of cold draw machine |

b) Advanced annealing machine |

c) Better mechanical property |

d) More precise dimension |

e) Perfect inspection method and inspection equipment etc |

Grade

| TP 304; TP304H; TP304L; TP316; TP316L; TP 321;TP321H; TP317L; TP310S; TP347H |

Standard

| ASTM A213, ASTM A 269, ASTM A 270,EN10216-5; ASTM B 622;ASTM B516;ASTM A789, etc |

| Size | OD:10.3-1219mm |

| WT:1.24-59.54mm | |

| Length:Max.12M | |

| Advantage | Superior surface finish ,better mechanical property; more precise dimension; perfect inspection method and inspection equipment |

| Application | Boiler tube applies to petroleum,chemical industry,electric power,boiler,high temperature resistant,low temperature resistant,corrosion resistant.The size can be made according to the customers requirements.High pressure boiler pipe applies to container,petrochemical and so on.Note:Generally,high pressure boiler pipe’s working pressure above 9.88Mpa and working temperature between 450 to 650. |

| Package | Plastic in both ends, then packed in iron case |

Product Description

| Outer Diameter | 10.3-1219mm |

| Wall Thickness | 1.24-59.54mm |

| NPS | 1/8"-24" |

| Schedule | 5/5S,10/10S,20/20S,40/40S,80/80S,120/120S,160/160S |

| Material Grade | 304/304L/316/316L/321/309S/310S, etc |

| Standard | ASTM A269, ASTM A312, etc |

| Application | used in Fluid and Gas Transport, Structure and Machining,etc |

| Certificates | ISO9001:2008, PED, BV |

| Process Method | Cold Drawn/ Cold Rolled |

| Surface Finish | Annealed/ Polished |

| Package | Woven bag for each piece, then packed in seaworthy wooden cases |

| Delivery Time | 20-60 Days after receiving the deposit (Normally according to the order quantity) |

| Price Item | FOB, CIF or as negotiation |

| Payment | T/T(30% in advance, 70% against the BL Copy) or as negotiation |

| Quality Requirement | Mill Test Certificate will be supplied with shipment, Third Part Inspection is acceptable |

| Main Market | Europe, Middle East, Southeast Asia, South America, etc |

MTSCO has been dedicated to producing seamless stainless steel pipe since 2003 , owning complete producing technology and abundant managing experience . Our raw material such as mother tube , round bar we use is from Chinese biggest and well known steel mill : Walsin , Yongxing etc . And We have advanced NDT equipments for the tests such as Eddy Current test, Ultrasonic test , Hydraulic test and so on . We have ISO 9001 and PED certificate , and the Third Party Inspection Certificates such as TUV , BV , Lloyd’s , SGS , etc , also can be provided according to customers’ requirements .

VIP SERVICE

VR (Virtual) Mill Introduction

Professional Remote Technical Guidanceion

Accept Third-party Inspection

Door to Door Shipment

Get QuoteRelated Products: Seamless Pipe: Stainless Steel Seamless Pipe

1.4306 / 1.4404 Annealed & Pickled Stainless Steel Seamless Pipe For Industry

Product Description: Outer Diameter: 10.3-1219mm Wall Thickness: 1.24-59.54mm (0.04''-2'' ) NPS: 1/8-24 Schedule: 5/5S,10/10S,20/20S,40/40S,80/80S,120/120S,160/160S Material Grade: 304/304L/316/316L/321/309S/310S, etc Standard: ASTM A269, ASTM A312, etc Application: used in Fluid and Gas......

TP316L / 321H Stainless Steel Seamless Pipe, ASTM A790 For Big Size

Stainless steel is an iron alloy that contains a minimum of 10.5% chromium. Alloying elements such as nickel, molybdenum, titanium, carbon, nitrogen, and copper can boost the strength, formability, and other properties of stainless steel. Seamless stainless steel pipe is used in applications wher......

English

English 中 文

中 文 Español

Español Português

Português Deutsch

Deutsch Türk

Türk Pусский

Pусский عربي

عربي 한국인

한국인 日本語

日本語