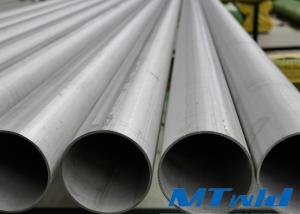

ASTM A789 / A790 1.4462 / 1.4410 Duplex Steel Big Size Welded Pipe With Annealed & Pickled Surface

SSDWP06

Material: S32101, 1.4162; S32205, S31803, 1.4462; S32304, 1.4362, UNS S32304; S32750,1.4410, 2507, F53; S32760, 1.4501;

Get Quote

ASTM A789 / A790 1.4462 / 1.4410 Duplex Steel Big Size Welded Pipe With Annealed & Pickled Surface

ASTM A269 - 10 : Standard Specification for Seamless and Welded Austenitic Stainless Steel Tubing for General Service

ASTM A312 / A312M - 12 : Standard Specification for Seamless , Welded , and Heavily Cold Worked Austenitic Stainless Steel Pipes

ASTM A789 / A789M - 10a : Standard Specification for Seamless and Welded Ferritic / Austenitic Stainless Steel Tubing for General Service

ASTM A790 / A790M - 11 : Standard Specification for Seamless and Welded Ferritic / Austenitic Stainless Steel Pipe

| UNS Designation | C | Si | Mn | P | S | Cr | Ni | Mo | N | Cu |

| max | max | max | max | max | ||||||

| S31803 | 0.03 | 1 | 2 | 0.03 | 0.02 | 21.0 - 23.0 | 4.5 - 6.5 | 2.5 - 3.5 | 0.08 - 0.20 | - |

| S32205 | 0.03 | 1 | 2 | 0.03 | 0.02 | 22.0 - 23.0 | 4.5 - 6.5 | 3.0 - 3.5 | 0.14 - 0.20 | - |

| S32750 | 0.03 | 0.8 | 1.2 | 0.035 | 0.02 | 24.0 - 26.0 | 6.0 - 8.0 | 3.0 - 5.0 | 0.24 - 0.32 | 0.5 max |

| S32760 | 0.05 | 1 | 1 | 0.03 | 0.01 | 24.0 - 26.0 | 6.0 - 8.0 | 3.0 - 4.0 | 0.20 - 0.30 | 0.50 -1.00 |

Application :

1 . For fluid and gas transport

2 . Structure and machining

3 . Heat exchanger pipes etc

Advantages :

1 . Superior surface finish

2 . Better mechanical property

3 . More precise dimension

4 . Perfect inspection method and inspection equipment

Test :

1 . X-ray , Size test , Length test

2 . Chemical Analysis ( Photoelectric Emission Spectroscopic ) etc

| Industry & Advantage | Application | a) Petroleum |

| b) Chemical industry | ||

| c) Instrument | ||

| d) Industrial transportation | ||

| e) Mechanical structure industry | ||

| f) Need high corrision ability pipe's industry, such as offshore industry etc | ||

| Advantages | a) Superior surface finish, | |

| b) Better mechanical property | ||

| c) More precise dimension | ||

| d) Perfect inspection method and inspection equipment | ||

| Terms & Conditions | Price Item | FOB, CFR, CIF or as negotiation |

| Payment | T/T, LC or as negotiation | |

| Delivery Time | 30 working days after received your deposit (Normally according to the order quantity) | |

| Package | Iron case; woven bag or as per customer’s requirement | |

| Quality Requirement | Mill Test Certificate will be supplied with shipment, Third Part Inspection is acceptable | |

| Quality | Test | NTD(Ultrasonic test, Eddy Current test); |

| Mechanical Test(Tension Test, Flaring Test, Flattening Test, Hardness Test, Hydraulic test); | ||

| Metal Test(Metallographic Analysis, Impact Test-High/low temperature); | ||

| Chemical Analysis(Photoelectric Emission Spectroscopic) | ||

| Market | Main Market | Europe, Middle East, Southeast Asia, South America. etc |

VIP SERVICE

VR (Virtual) Mill Introduction

Professional Remote Technical Guidanceion

Accept Third-party Inspection

Door to Door Shipment

Get QuoteRelated Products: Welded Pipe: Duplex Steel Welded Pipe

ASTM A790 / ASME SA790 F51 / F53 Duplex Steel Welded Pipe For Transportation

1. Material Grade: S32205 , S31803 , S32304 , S32750, F51 , F53 , 2205 , 2507 etc 2. Outer Diameter: 10.3mm-1219mm Wall Thickness : 1.24mm-59.54mm 3. Length: Normally fixed length 6m , can as per customer’s requirement 4. Standard: ASTM A312 ; ASTM A358 ; ASTM A789 ; ASTM A790 ect . 5. Proce......

S32750 F53 1.4410 Duplex Steel Big Size Annealed & Pickled Welded Pipe

ASTM A269 - 10 : Standard Specification for Seamless and Welded Austenitic Stainless Steel Tubing for General Service ASTM A312 / A312M - 12 : Standard Specification for Seamless , Welded , and Heavily Cold Worked Austenitic Stainless Steel Pipes ASTM A789 / A789M - 10a : Standard Specification ......

S32750 / S32760 1.4410 Duplex Stainless Steel Annealed & Pickled Welded Pipe

Outer Diameter: 10.3mm-1219mm Wall Thickness: 1.24mm-59.54mm Length: Normally fixed length 6m , can as per customer's requirement Standard: ASTM A312 ; ASTM A358 ; ASTM A789 ; ASTM A790 etc . Process Method: ERW , EFW etc MTSCO has been dedicated to producing welded pipe and tube since 2003......

English

English 中 文

中 文 Español

Español Português

Português Deutsch

Deutsch Türk

Türk Pусский

Pусский عربي

عربي 한국인

한국인 日本語

日本語