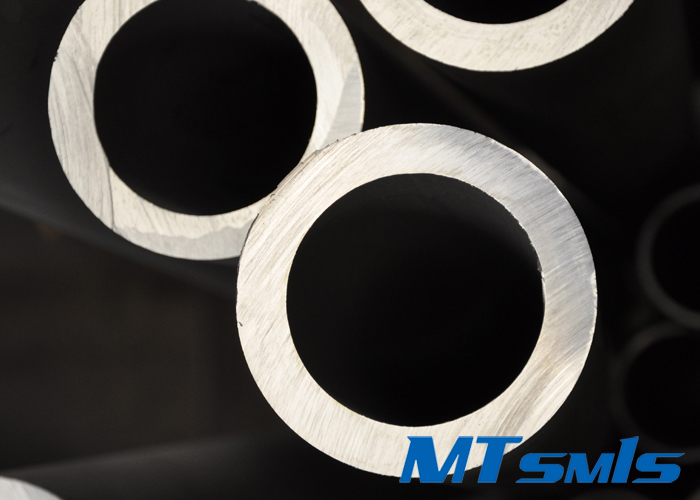

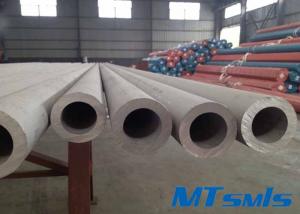

ASTM A790 / ASME SA790 Duplex Steel Pipe For Heat Coils, 6000mm Stainless Seamless Pipe

SSDSP35

Price: From $5000-9000USD/TON

Material: S32205, S31803, 1.4462; S32750,1.4410, 2507, F53;

Get Quote

ASTM A790 / ASME SA790 Duplex Steel Pipe For Heat Coils, 6000mm Stainless Seamless Pipe

Most of 2507 duplex steel pipes are produced by cold drawn method . The alloy has higher yield strength and lower ductility than austenitic steels so fabricators may fid that higher forming forces , increased radius of bending , and increased allowance for springback are necessary . Deep drawing , stretch forming , and similar processes are more difficult to perform on 2507 than on an austenitic stainless steel . When forming requires more than 10% cold deformation , a solution anneal and quench are recommended . And finished cold drawn duplex steel pipe , manufacturer should be solution annealed and quenched . The minimum annealing tempeture is 19250F . Annealing should be followed immediately by a rapid air or water quench. To obtain maximum corrosion resistance, heat treated products should be pickled and rinsed .

Material Grade: S32205, S31803, S32304, S32750, F51, F53, 2205, 2507 etc

Outer Diameter: 10.3mm-1219mm

Wall Thickness: 1.24mm-59.54mm

Length: Normally fixed length 6m, can as per customer’s requirement

Standard: ASTM A789; ASTM A790; EN 10216-5 etc.

Process Method: Cold Drawn or Cold Rolled

Application

a) Petroleum

b) Chemical industry

c) Instrument

d) Industrial transportation

e) Mechanical structure industry

f) Need high corrision ability pipe's industry, such as offshore industry etc

Advantages

a) Superior surface finish,

b) Better mechanical property

c) More precise dimension

d) Perfect inspection method and inspection equipment

| Grade | C | Si | Mn | P | S | Cr | Ni | Mo | N |

| max | max | max | max | max | |||||

| UNS S32750 | 0.03 | 0.8 | 1.2 | 0.03 | 0.015 | 24.0-26.0 | 6.0-8.0 | 3.0-5.0 | 0.24-0.32 |

| UNS S31803 | 0.03 | 1 | 2 | 0.02 | 0.02 | 21.0-23.0 | 4.5-6.5 | 2.5-3.5 | 0.08-0.20 |

| UNS S31500 | 0.03 | 1 | 1.2-2.0 | 0.03 | 0.03 | 18.0-19.0 | 4.5-5.5 | 2.5-3.5 | 0.05-0.10 |

| Physical Properties | ||||

| Grade | Y.S.MPa min | T.S.Mpa min | Elongation % | Hardness HRC |

| UNS S32750 | 550 | 800 | 15 | 20 |

| UNS S31803 | 450 | 620 | 25 | 20 |

| UNS S31500 | 440 | 630 | 30 | 20 |

VIP SERVICE

VR (Virtual) Mill Introduction

Professional Remote Technical Guidanceion

Accept Third-party Inspection

Door to Door Shipment

Get QuoteRelated Products: Seamless Pipe: Duplex Steel Seamless Pipe

Duplex Steel Tube ASTM A790 S32750 / 2507 6096mm Length ISO 9001

ASTM A790 2507 duplex steel pickling tube are always purchased by the clients who need high corrosion tubes . Compared to stainless steel tubes , duplex steel tubes have more higher corrosion ability . They can be used in sea industry . Material Grade: S32205 , S31803 , S32304 , S32750 , F5......

8 Inch Sch40s Duplex Steel Seamless Pipe Big Size SAF2205 / 2507

Duplex stainless steel that was developed to combat common corrosion problems encountered with the 300 series stainless steels . Duplex describes a family of stainless steels that are neither fully austenitic , like 304 stainless , nor purely ferritic , like 430 stainless . The advantage of a duplex......

ASTM A789 / A790 2205 / 2507 Duplex Steel Seamless Pipe With Cold Rolled

Duplex stainless steel that was developed to combat common corrosion problems encountered with the 300 series stainless steels . Duplex describes a family of stainless steels that are neither fully austenitic , like 304 stainless , nor purely ferritic , like 430 stainless . The advantage of a duplex......

English

English 中 文

中 文 Español

Español Português

Português Deutsch

Deutsch Türk

Türk Pусский

Pусский عربي

عربي 한국인

한국인 日本語

日本語