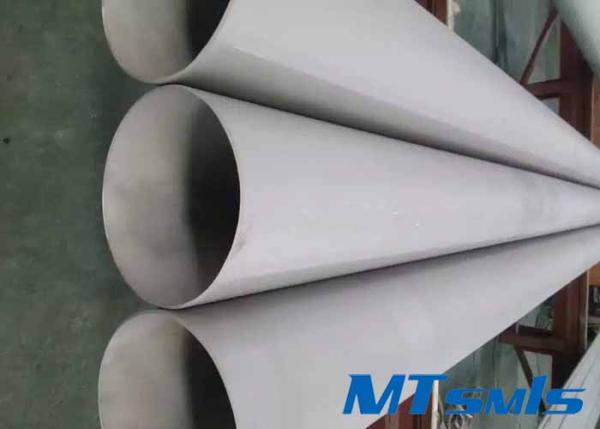

Corrosion Resistant Alloy C22 Pipes for Harsh Chemical Processing Environments

SSNAWP04

Material: Alloy C22, UNS N06022;

Get Quote

C22 pipe/tube:

Parameter Table:

Specifications of C22 pipe/tube

| |||

Grade | Standard | Outside Diameter | 8mm-711mm/3.18mm-38mm

|

Alloy 600 | ASTM-B444 | Wall Thickness | 1mm-50mm/3.18mm-38mm

|

Length | ≤20m/≤30m

| ||

Inspection | Appearance/ Dimensional test, PMI; | ||

Certificates | ISO/PED/AD2000/TS | ||

Package | End protection/ Woven bags/ Wooden cases | ||

Factory advantages and features:

Huxin Pipe, a seamless steel pipe manufacturer owned by MTSCO Investments, is trusted for its 36 years of experience in pipe manufacturing. The factory not only supplies regular sized pipes, but can also provide extended pipe lengths of 18 and 25 metres to meet the needs of different customers.

Huxin Pipe's factory is well-equipped, including cold rolling mill, annealing furnace, pickling tank, ultrasonic eddy current machine, and physical and chemical laboratories, etc. These advanced equipments provide a strong guarantee for the manufacturing of seamless steel pipes.

In terms of quality control, HUXIN PIPE has a set of perfect quality control process, and professional MTSCO QC inspectors are involved in the whole process of control before, during and after production, which provides customers with more reliable product quality guarantee.

In addition, Huxin Pipe's products have passed ISO, PED and AD2000 certifications, which proves its strength and reputation in quality.

Introduction to Quality Control Inspection Methods:

Raw Material Quality Control

MTSCO's pipe raw materials are sourced from reputable steel mills like Baosteel and Tsingshan. To guarantee quality, each batch of raw materials must come with a warranty and PMI (Positive Material Identification) test report. We conduct stringent PMI and other inspections to verify that the materials meet the specified requirements.

In-Production Process Control

MTSCO's seamless pipe production processes encompass cold rolling, cold drawing, annealing, pickling, surface treatment, and more. Each stage utilizes advanced production equipment, overseen by our team of experienced engineers and technicians. Every step is meticulously supervised and documented photographically for archival purposes. We employ process cards to ensure the accuracy and traceability of the entire production process.

Quality Control Prior to Shipment

MTSCO boasts a dedicated QC (Quality Control) team that meticulously inspects and tests each product, covering aspects such as appearance, PMI, dimensions, quantity, and more. We also conduct mechanical testing, hardness testing, ultrasonic testing, eddy current testing, hydraulic testing, and other specialized evaluations. Additionally, we welcome third-party testing from reputable organizations like SGS, TUV, and BV. Prior to shipment, we employ appropriate and secure packaging methods, including container reinforcement, to safeguard the goods against damage during transportation.

Packing of C22 Pipe/Tube:

Product | Packing |

LCL PIPE | Plywood crate + protective pipe caps on both ends |

FCL PIPE | Woven bag + protective pipe caps on both ends |

LCL/FCL TUBE | Plywood crate + individual plastic bag wrapping + end caps on both sides |

Chemical Composition:

Element | Alloy C22 / N06022 |

C max | 0 |

Si max | 0 |

Mn max | 1 |

P max | 0 |

S max | 0 |

Cr | 20.0–22.5 |

Ni | balance |

Mo | - |

Ti | - |

N max | - |

Cu max | - |

Nb | - |

Al max | - |

Co max | 2.5 |

Zr | - |

Fe max | 2–6 |

Tu | - |

Va | - |

Physical Properties:

Grade | Physical Property | |||

Y.S | T.S | EL. | HB | |

Alloy C22/N06022 | ≥283 | ≥690 | ≥40 | - |

VIP SERVICE

VR (Virtual) Mill Introduction

Professional Remote Technical Guidanceion

Accept Third-party Inspection

Door to Door Shipment

Get QuoteRelated Products: Seamless Pipe: Nickel Alloy Cobalt Alloy Seamless Pipe

ASME SB163 / SB423 Nickel Alloy Seamless Alloy 825 Pipe

Apart from nickel being the primary alloying material in the alloy 825 electropolish pipe, the alloy also contains elements such as iron, chromium, titanium, molybdenum, and copper. Alloy 825 has excellent resistance to chloride-ion-induced stress corrosion cracking, reducing environments contain......

Monel 400 Nickel Alloy Tubes for High-Temperature Industrial Heat Transfer Applications

Monel 400 is a nickel-copper alloy with nickel (about 63%) and copper (about 30%) as the main components. It has excellent corrosion resistance and good mechanical properties and is widely used in various harsh environments. Its common forms include Monel 400 pipes (pipe/tube), which are suitable fo......

English

English 中 文

中 文 Español

Español Português

Português Deutsch

Deutsch Türk

Türk Pусский

Pусский عربي

عربي 한국인

한국인 日本語

日本語