Explosion welding: a highly efficient process for joining metals

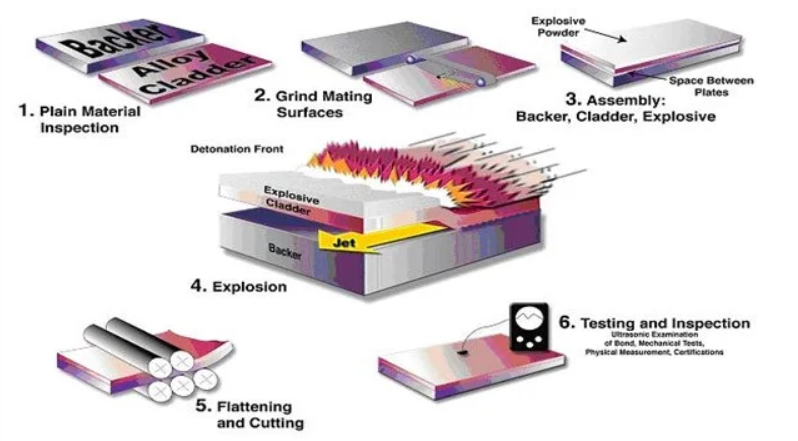

Explosives are placed between two metal plates, which are instantly fused together after detonation. Why use explosives for metal welding? This is Explosion Welding (Explosion Welding), a solid-state welding technology that relies on high-energy impact to achieve metal bonding.

Principles of Explosion Welding

Explosion welding is mainly used to make metal composite plates, through the explosive instant release of high temperature and high pressure, so that different metal plates in a very short period of time to form a metallurgical bond. Its welding structure includes:

· Base Plate (Base Plate): provides structural support;

· Cladding Plate: gives the final product corrosion resistance or high strength properties;

· buffer layer (Buffer Layer): to regulate the explosive energy, to prevent damage to the plate;

· explosives and detonators: to provide shock energy to trigger the welding process.

After the explosion occurs, the shock wave makes the cladding plate at a very high speed into the substrate, extrusion of air and oxides in the gap, the formation of high-strength metallurgical bond. Compared to conventional welding, explosion welding not only joins dissimilar metals, but also completes dozens of square meters in less than a second.

Process classification and application:

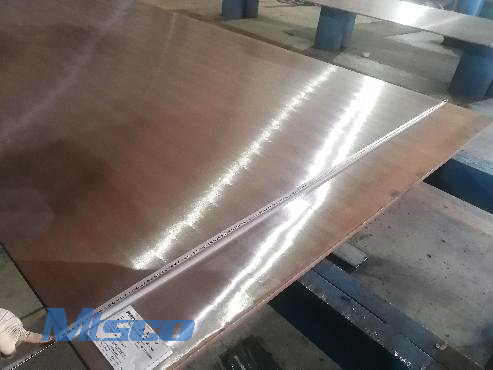

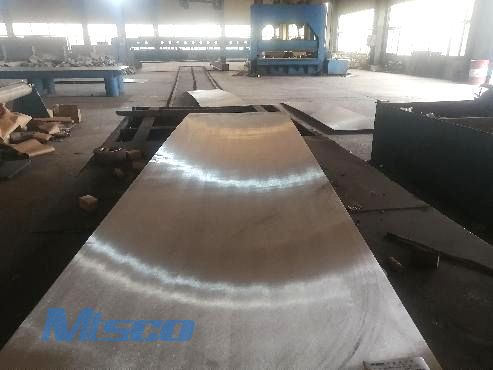

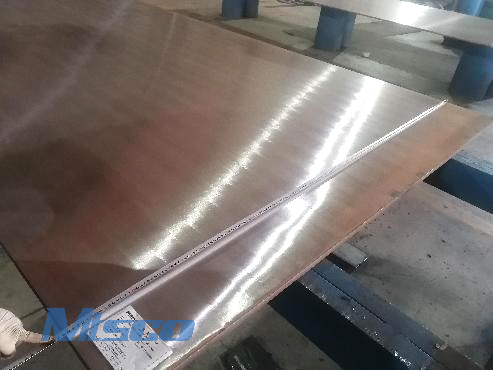

According to the form of joints, explosion welding can be divided into face explosion welding, wire explosion welding and spot explosion welding, of which the face explosion welding is the most widely used, commonly used in petrochemical, marine engineering, heat exchange equipment, aerospace and other industries. A batch of MONEL 400 composite panels recently produced by MTSCO, it is the use of the explosion welding process, to ensure high-quality bonding effect, and the final product performance.

|  |

Other Applications of Explosion Technology:

In addition to welding, explosion energy can also be used for explosion molding (Explosive Forming), such as metal sphere impact molding and underwater metal shaping. Through the action of the blast wave, metal sheets can be quickly formed for high-precision equipment manufacturing.

MTSCO: Your Specialized Metal Welded Pipe Supplier

MTSCO specializes in high-end metal materials and welding technology, providing nickel alloy seamless/welded pipes, explosion-welded composite plates and other products, which are widely used in extreme working conditions. Welcome to consult and cooperate with us, we provide you with the best quality metal connection solutions!

English

English 中 文

中 文 Español

Español Português

Português Deutsch

Deutsch Türk

Türk Pусский

Pусский عربي

عربي 한국인

한국인 日本語

日本語