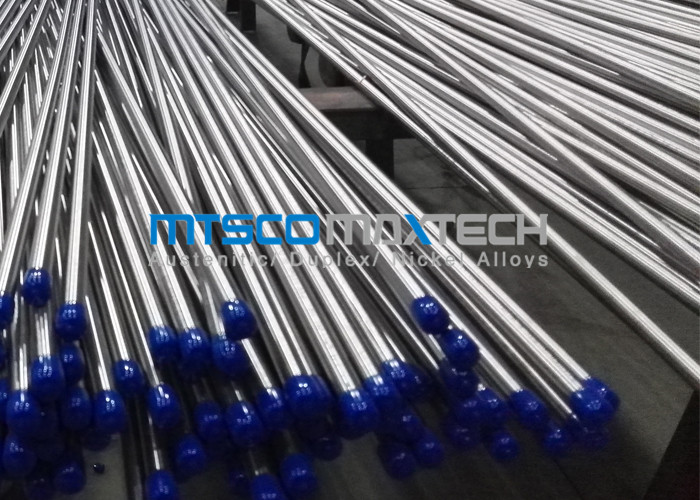

High Durability super duplex tubing ASME SA789 S32205 Polishing

SSDST04

Price: From $5500-8000USD/TON

Material: S32205, S31803, 1.4462; S32304, 1.4362, UNS S32304; S32750,1.4410, 2507, F53; S32760, 1.4501;

Get Quote

High Durability super duplex tubing ASME SA789 S32205 Polishing

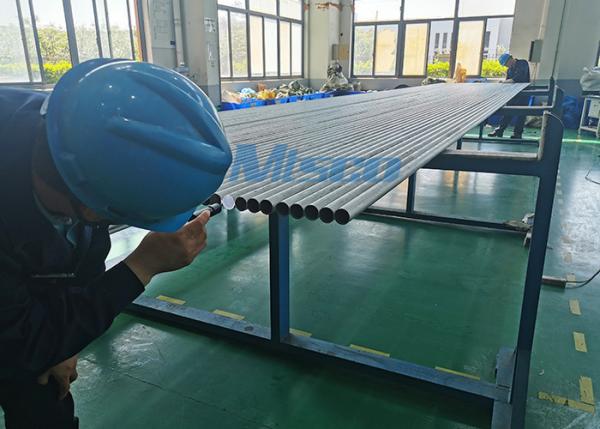

MTSCO is specialized in duplex steel pipes produce . So we know good at duplex steel knowledge . Hope the clients who are choose us can be very assured . And no need worry about our produce ability. We , MTSCO , is worth for your belived .

Most of 2507 duplex steel pipes are produced by cold drawn method . The alloy has higher yield strength and lower ductility than austenitic steels so fabricators may fid that higher forming forces , increased radius of bending , and increased allowance for springback are necessary . Deep drawing , stretch forming , and similar processes are more difficult to perform on 2507 than on an austenitic stainless steel . When forming requires more than 10% cold deformation , a solution anneal and quench are recommended . And finished cold drawn duplex steel pipe , manufacturer should be solution annealed and quenched . The minimum annealing tempeture is 19250F . Annealing should be followed immediately by a rapid air or water quench. To obtain maximum corrosion resistance, heat treated products should be pickled and rinsed .

| ASTM/UNS | C (max) | Si (max) | Mn (max) | P (max) | S (max) | Cr | Ni | Mo | Ti |

| TP304/S30400 | 0.080 | 1.00 | 2.00 | 0.045 | 0.03 | 18.0-20.0 | 8.0-10.5 | ||

| TP304L/S30403 | 0.035 | 1.00 | 2.00 | 0.045 | 0.03 | 18.0-20.0 | 8.0-13.0 | ||

| TP304H/S30409 | 0.04-0.10 | 1.00 | 2.00 | 0.045 | 0.03 | 18.0-20.0 | 8.0-11.0 | ||

| TP316/S31600 | 0.080 | 1.00 | 2.00 | 0.045 | 0.03 | 16.0-18.0 | 11.0-14.0 | 2.0-3.0 | |

| TP316L/S31603 | 0.035 | 1.00 | 2.00 | 0.045 | 0.03 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 | |

| TP316Ti/S31635 | 0.080 | 1.00 | 2.00 | 0.045 | 0.03 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 | 0.7>5x(C+N) |

| TP321/S32100 | 0.080 | 1.00 | 2.00 | 0.045 | 0.03 | 17.0-19.0 | 9.0-12.0 | 0.7>5x(C+N) | |

| TP317L/S31703 | 0.035 | 1.00 | 2.00 | 0.045 | 0.03 | 18.0-20.0 | 11.0-15.0 | 3.0-4.0 | |

| TP347H/S34709 | 0.04-0.10 | 1.00 | 2.00 | 0.045 | 0.03 | 17.0-19.0 | 9.0-13.0 | ||

| TP309S/S30908 | 0.080 | 1.00 | 2.00 | 0.045 | 0.03 | 22.0-24.0 | 12.0-15.0 | 0.75 | |

| TP310S/S31008 | 0.080 | 1.00 | 2.00 | 0.045 | 0.03 | 24.0-26.0 | 19.0-22.0 | 0.75 |

VIP SERVICE

VR (Virtual) Mill Introduction

Professional Remote Technical Guidanceion

Accept Third-party Inspection

Door to Door Shipment

Get QuoteRelated Products: Seamless Tube: Annealed Pickled Heat Exchanger Tube

ASTM A789 1.4462 / S32205 Stainless Steel Duplex Tube With Good Impact Toughness

Material Grade: S32205 , S31803 , S32304 , S32750, F51 , F53 , 2205 , 2507 etc Outer Diameter: 3.18mm - 101.6mm Wall Thickness: 0.5mm - 20mm Length: as per customer’s requirement Standard: ASTM A789 ; ASTM A790 ; EN 10216-5 etc. Features : 1 . Outstanding resistance to pitting and cre......

F51 / F53 Small Diameter Duplex Steel Tube, ASTM A789 / A790 Cold Rolled Tube

MTSCO is specialized in duplex steel pipes produce . So we know good at duplex steel knowledge . Hope the clients who are choose us can be very assured . And no need worry about our produce ability. We , MTSCO , is worth for your belived . Most of 2507 duplex steel pipes are produced by cold draw......

English

English 中 文

中 文 Español

Español Português

Português Deutsch

Deutsch Türk

Türk Pусский

Pусский عربي

عربي 한국인

한국인 日本語

日本語