Nickel Alloy, What's That Material ?

Nickel alloys are alloys that contain more than 30% by weight of nickel, and common products have more than 50% by weight of nickel. They have superior mechanical strength and corrosion resistance at high temperatures, and are called superalloys along with iron-based and cobalt-based alloys. They are usually used in environments above 540°C. Different alloys are chosen for the design of the alloys depending on the use occasion, which are used in special corrosion-resistant environments, corrosive environments at high temperatures, and equipment that requires high-temperature mechanical strength.

Nickel alloys were developed in the late 1930s. In 1941, Britain first produced the nickel-based alloy Nimonic 75 (Ni-20Cr-0.4Ti), and then added Al to improve the creep strength, developing Nimonic 80 (Ni-20Cr- 2.5Ti-1.3Al). The United States, Russia and China also developed nickel-based alloys in the mid-1940s, late 1940s and mid-1950s respectively. The development of nickel-based alloys involves two aspects, namely the improvement of alloy composition and the innovation of production technology.

In order to meet the needs of ships and industrial gas turbines, since the 1960s, some high Cr nickel-based alloys with better thermal corrosion resistance and stable structure have also been developed. So far, nickel-based alloys can be used above 1100°C, from the initial simple Nimonic75 alloy with the aforementioned composition, to the recently developed MA6000 alloy, which has a tensile strength of 2220MPa and a yield strength of 192MPa at 1100°C; the creep strength at 1100°C/137MPa is about 1000 hours, which can be used for aero-engine blades.

Characteristics of nickel alloys

(1) Excellent performance: they maintain high strength at high temperatures, and have excellent mechanical properties such as creep resistance and fatigue resistance, as well as oxidation resistance and corrosion resistance, and good plasticity and weldability.

(2) Extremely complex alloy addition: Nickel-based alloys often add more than ten alloying elements to enhance the corrosion resistance in different environments, as well as effects such as solid solution strengthening or precipitation strengthening.

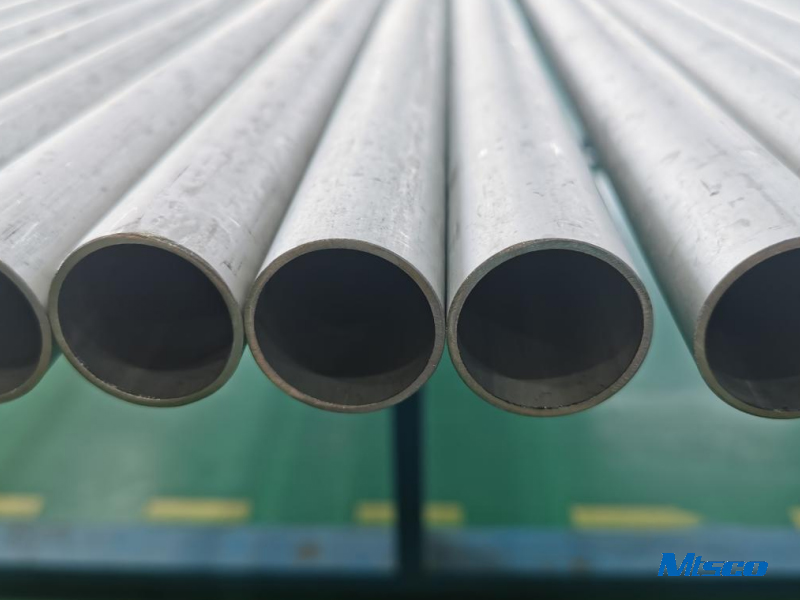

(3) Very harsh working environment: Nickel-based alloys are widely used in various harsh conditions, such as high-temperature and high-pressure parts of gas chambers of aerospace engines, structural parts of nuclear energy, petroleum and marine industries, and corrosion-resistant pipelines.

After more than ten years of development, nickel alloy has become MTSCO’s star product, covering grades such as Alloy 600/601/625/825/400/200, etc., and products covering seamless pipe, welded pipe, coiled pipe, pipe fittings, flanges, plates etc. Want to solve the procurement problem of nickel alloy? Contact us to provide you with cost-effective solutions and products.

English

English 中 文

中 文 Español

Español Português

Português Deutsch

Deutsch Türk

Türk Pусский

Pусский عربي

عربي 한국인

한국인 日本語

日本語