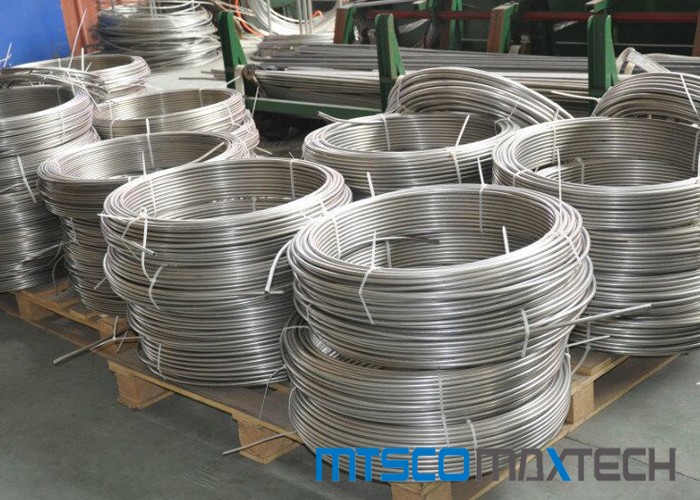

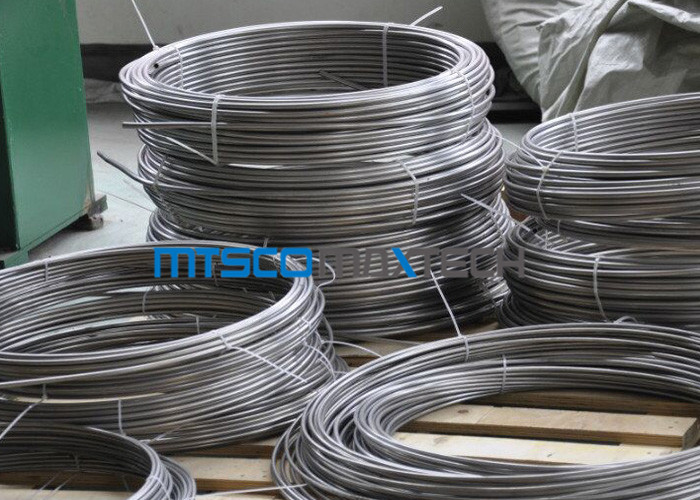

ASTM A789 S31803/S32205/2205/S32750/2507 Coiled Tubing Equipment

SSSCT06

Material: S32101, 1.4162; S32205, S31803, 1.4462; S32304, 1.4362, UNS S32304; S32750,1.4410, 2507, F53;

Get Quote

S31803 ASTM A789 / A790 Duplex Steel Coiled Tube For Chemical Industry

| UNS Designation | C | Si | Mn | P | S | Cr | Ni | Mo | N | Cu |

| max | max | max | max | max | ||||||

| S31803 | 0.03 | 1 | 2 | 0.03 | 0.02 | 21.0 - 23.0 | 4.5 - 6.5 | 2.5 - 3.5 | 0.08 - 0.20 | - |

| S32205 | 0.03 | 1 | 2 | 0.03 | 0.02 | 22.0 - 23.0 | 4.5 - 6.5 | 3.0 - 3.5 | 0.14 - 0.20 | - |

| S32750 | 0.03 | 0.8 | 1.2 | 0.035 | 0.02 | 24.0 - 26.0 | 6.0 - 8.0 | 3.0 - 5.0 | 0.24 - 0.32 | 0.5 max |

| S32760 | 0.05 | 1 | 1 | 0.03 | 0.01 | 24.0 - 26.0 | 6.0 - 8.0 | 3.0 - 4.0 | 0.20 - 0.30 | 0.50 -1.00 |

Size | OD : 4.76 - 25.4mm |

WT : 0.71 - 2.11mm | |

Length : >1000Meters | |

4.76 * 0.71mm / 4.76 * 0.89mm / 4.76 * 1.24mm | |

6 * 1mm / 6 * 1.5mm | |

6.35 * 0.71mm / 6.35 * 0.89mm / 6.35 * 1.24mm / 6.35 * 1.65mm | |

7.94 * 0.71mm / 7.94 * 0.89mm / 7.94 * 1.24mm / 7.94 * 1.65mm | |

9.53 * 0.71mm / 9.53 * 0.89mm / 9.53 * 1.24mm / 9.43 * 1.65mm | |

10 * 1mm / 10 * 1.5mm | |

12 * 1mm / 12 * 1.5mm / 12 * 2mm | |

12.7 * 0.71mm / 12.7 * 0.89mm / 12.7 * 1.24mm / 12.7 * 1.65mm / 12.7 * 2.11mm | |

14 * 1mm / 14 * 1.5mm / 14 * 2mm | |

15.88 * 0.89mm / 15.88 * 1.24mm / 15.88 * 1.65mm / 15.88 * 2.11mm | |

16 * 1mm / 16 * 1.5mm / 16 * 2mm | |

19.05 * 0.89mm / 19.05 * 1.24mm / 19.05 * 1.65mm / 19.05 * 2.11mm | |

25.4 * 0.89mm / 25.4 * 1.24mm / 25.4 * 1.65mm / 25.4 * 2.11mm |

Inspection & Test

1 .100 % PMI , Spectro Chemical Aanlysis Test for Raw Material

2 .100 % Dimension & Visual Examination

3 . Mechanical Properties Test Include Tension Test,Flaring Test ( For Seamless tube / pipe ) / Flange Test ( For Welded Pipe & Tube ) , Hardness Test , Reversed Flattening Test

4 .100 % Hydrostatic Test or 100 % NON - DESTRUCTIVE Test ( ET or UT )

5 . Radiographic Test for Welded Pipe ( shall be accordance with specification , or shall be as agreed upon between the purchaser and vendor )

6 . Straightness Test ( optional )

7 . Roughness Test ( optional )

8 . Intergranular Corrosion Test ( optional )

9 . Impact Test ( optional )

10 . Grain Size Determinations ( optional )

NOTES : ALL THE TESTS AND INSPECTION RESULT NEED TO BE SHOWED IN REPORTS ACCORDING TO STANDARD AND SPECIFICATION .

VIP SERVICE

VR (Virtual) Mill Introduction

Professional Remote Technical Guidanceion

Accept Third-party Inspection

Door to Door Shipment

Get QuoteRelated Products: Coiled Tubing, Control Line: Welded / Seamless Coiled Tubing

Tubing capilar sin costura de acero inoxidable ASTM A269 TP304 / 304L de 1/4 pulgadas para petróleo y gas

El tubo enrollado sin costura está disponible principalmente para el tubo hidráulico, el tubo de instrumentación de acero inoxidable, el tubo capilar y el tubo recocido brillante. Este producto se fabrica por el método de estirado en frío / laminado en frío....

Stainless Steel Spiral Wound Tube 304L/ 316L Cold Rolled For Oil Drilling

What is Spiral Wound Tube? Spiral Wound Tube (SWT) is a type of pipe construction made by alternately winding metal strips with packing. This type of pipe construction is often used to make sealing elements such as packing gaskets and sealing washers to ensure the tightness of pipes and vessels....

1 / 8 Inch TP304 / 304L Stainless Steel Welded Super Long Coiled Tube For Food Industry

Material Grade : American Standard: TP304 , TP304L , TP310S , TP316 , TP316L , TP316Ti , TP321 , TP347 , 904L Etc European Standard: 1.4301 , 1.4306 , 1.4845 , 1.4401 , 1.4404 , 1.4571 , 1.4541 , 1.4550 , 1.4539 Etc German Standard: X5CrNi18-10 , X2CrNi19-11 , X12CrNi25-21 , X5CrNi17-12-2 ......

English

English 中 文

中 文 Español

Español Português

Português Deutsch

Deutsch Türk

Türk Pусский

Pусский عربي

عربي 한국인

한국인 日本語

日本語