UNS S31600 Pipe,UNS S31600 Stainless Steel Seamless Pipe

MT A269/S31600

Material: 316L, 1.4401, 1.4404, 1.4435; 316Ti, S31615, 1.4571, S31635;

Get Quote

UNS S31600 Pipe,UNS S31600 High Performance Stainless Steel Seamless Pipe in Petroleum Refining

UNS S31600 is a molybdenum-containing austenitic stainless steel with greater resistance to general corrosion and pitting/crevice corrosion than conventional chromium-nickel austenitic stainless steels such as 304, as well as higher creep, fracture stress, and tensile strength at elevated temperatures. In addition to its excellent corrosion resistance and strength properties, 316 has excellent fabricability and formability. It is also known as marine grade stainless steel.

| Grade | Standard | Outside Diameter | 8mm-711mm |

| TP304 TP304L TP316 TP316L TP317L TP321 TP321H TP347 TP347H TP904L | ASTM-A312 ASTM-A790 ASTM-B167/163 ASTM-B444 ASTM-B622 ASTM-B423 EN10216 GOST ...... | Wall Thickness | 1mm-50mm |

| Length | ≤20m | ||

| Inspection | Appearance/ Dimensional test, PMI; NDT: UT/ ET/ HT; Physical & chemical test | ||

| Certificates | ISO/PED/AD2000/TS | ||

| Package | End protection/ Woven bags/ Wooden cases |

|  |

Chemical Composition:

| Material | C(max) | Si(max) | Mn(max) | P(max) | S(max) | Cr | Ni | Mo | Ti |

| TP304/1.4301 | 0.08 | 1 | 2 | 0.045 | 0.03 | 18.0-20.0 | 8.0-10.5 | ||

| TP304L/1.4307 | 0.035 | 1 | 2 | 0.045 | 0.03 | 18.0-20.0 | 8.0-12.0 | ||

| TP304H/1.4948 | 0.04-0.10 | 1 | 2 | 0.045 | 0.03 | 18.0-20.0 | 8.0-12.0 | ||

| TP316/1.4401 | 0.08 | 1 | 2 | 0.045 | 0.03 | 16.0-18.0 | 11.0-14.0 | 2.0-3.0 | |

| TP316L/1.4404 | 0.035 | 1 | 2 | 0.045 | 0.03 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 | |

| TP316Ti/1.4571 | 0.08 | 1 | 2 | 0.045 | 0.03 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 | 0.7>5x(C+N) |

| TP321/1.4541 | 0.08 | 1 | 2 | 0.045 | 0.03 | 17.0-19.0 | 9.0-12.0 | 0.7>5x(C+N) | |

| TP317L/1.4449 | 0.08 | 1 | 2 | 0.045 | 0.03 | 18.0-20.0 | 11.0-14.0 | 3.0-4.0 | |

| TP347H/1.4912 | 0.04-0.10 | 1 | 2 | 0.045 | 0.03 | 17.0-19.0 | 9.0-13.0 | ||

| TP309S/1.4833 | 0.08 | 1 | 2 | 0.045 | 0.03 | 22.0-24.0 | 12.0-15.0 | 0.75 | |

| TP310S/1.4845 | 0.08 | 1 | 2 | 0.045 | 0.03 | 24.0-26.0 | 19.0-22.0 | 0.75 |

Physical Property:

| Steel grade | Physical Property | |||

| Y.S | T.S | EL. | HRB | |

| 304 | ≥205 | ≥515-1035 | ≥40 | ≤92 |

| 304L | ≥205 | ≥520 | ≥40 | ≤90 |

| 316 | ≥620 | ≥310 | ≥30 | ≤95 |

| 316L | ≥480 | ≥177 | ≥40 | ≤90 |

| 321 | ≥205 | ≥515 | ≥40 | ≤95 |

| 347 | ≥205 | ≥515 | ≥40 | ≤92 |

Benefits:

- Higher creep stress and rupture properties when compared with 304

- Ideal for high temperature service

- Overcomes sensitization and intergranular corrosion concerns

- Can be used in elevated temperature applications for ASME Boiler and Pressure Vessel Code applications

- Due to stabilisation the material offers better overall corrosion resistance when compared to 304/304L

- Excellent mechanical properties

Applications:

316 Stainless Steel Seamless Tube is a kind of hollow long round steel, which is widely used in industrial pipelines and mechanical structural parts for petroleum, chemical, medical, food, light industry, mechanical instrumentation and so on. In addition, it is lighter in weight with the same bending and torsion strength, so it is also widely used in the manufacture of mechanical parts and engineering structures. Also commonly used in the production of a variety of conventional equipment, gun barrels, shells, etc..

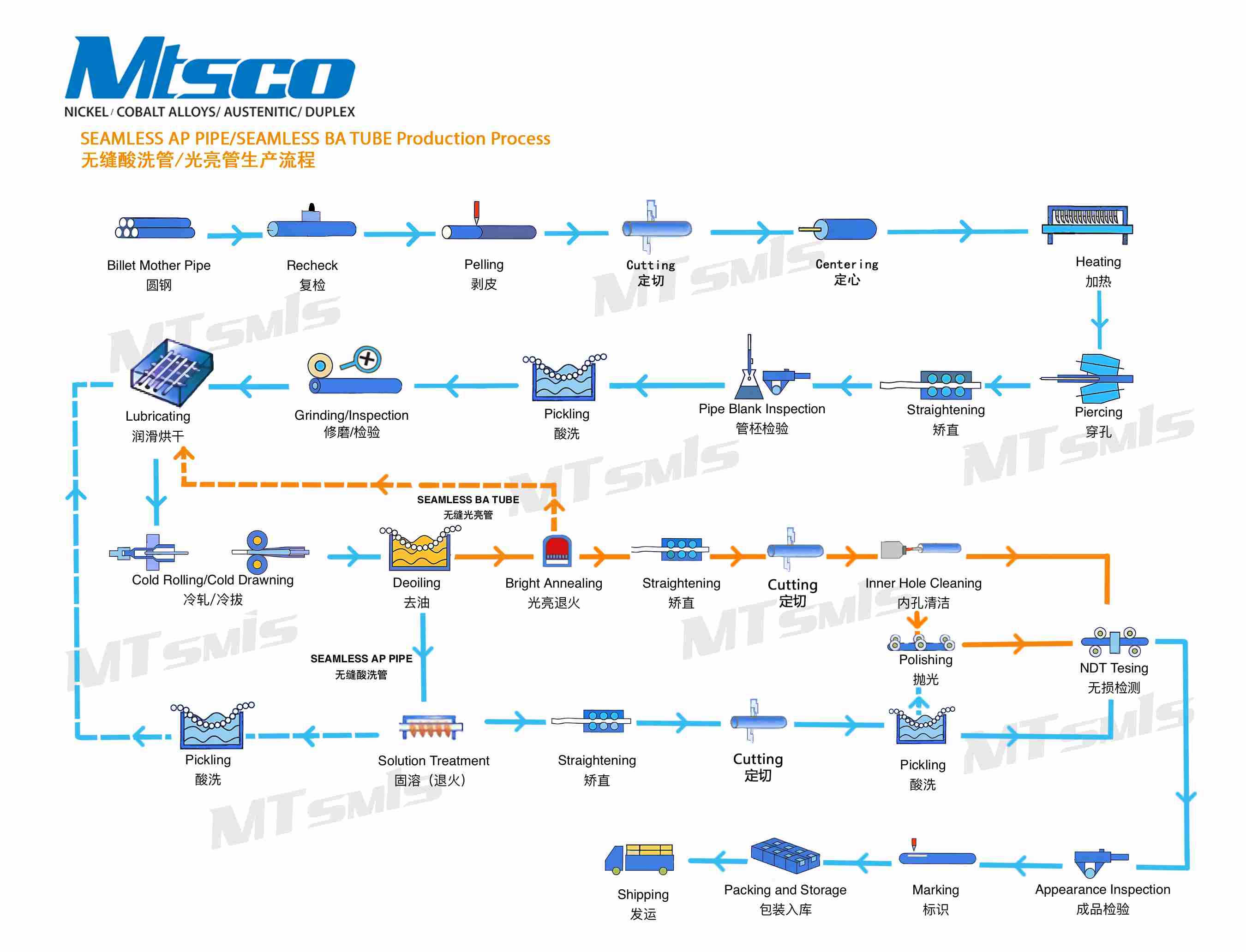

Production Process:

Quality Control:

1. Quality control of raw materialsFirst, secondary inspection of raw materials

Our raw materials come from large factories such as Baosteel and TSINGSHAN. Each batch of raw materials requires MTC and PMI. After the raw materials arrive, we conduct PMI and other inspections again to ensure that they meet the requirements

2. Quality control during productionSecond, traceability of the production process

Each process is equipped with advanced production equipment, and is supervised by experienced engineers and technicians. Each link is supervised by professional qc inspectors and photographed for archiving. The entire process uses process cards to ensure accuracy and traceability.

3. Quality control before shipmentThird, 100% inspection before shipment

MTSCO has professional QC team to conduct a series of inspections and experiments on the Pipes, including routine appearance, PMI, size, quantity, and other inspections. At the same time, we also conducts mechanical testing, hardness testing, UT, ET, HT and other tests. In addition, we also accept third-party inspection, such as SGS, TUV, and BV.

Before shipping, we use appropriate and safe packaging methods and take measures such as container reinforcement to ensure that your goods are delivered to you in good condition.

VIP SERVICE

VR (Virtual) Mill Introduction

Professional Remote Technical Guidanceion

Accept Third-party Inspection

Door to Door Shipment

Get QuoteRelated Products: Seamless Pipe: Stainless Steel Seamless Pipe

TP316L / 321H Stainless Steel Seamless Pipe, ASTM A790 For Big Size

Stainless steel is an iron alloy that contains a minimum of 10.5% chromium. Alloying elements such as nickel, molybdenum, titanium, carbon, nitrogen, and copper can boost the strength, formability, and other properties of stainless steel. Seamless stainless steel pipe is used in applications wher......

ASTM A312 TP347H Stainless Steel Seamless Pipe For Fluid Transportation

MTSCO has been dedicated to producing seamless stainless steel pipe since 2003 , owning complete producing technology and abundant managing experience . Our raw material such as mother tube , round bar we use is from Chinese biggest and well known steel mill : Walsin , Yongxing etc . And We have adv......

DN80 Stainlss Steel Sesamless Annealed & Pinkled Pipe For Fluid And Gas Transportation

MTSCO has been dedicated to producing seamless stainless steel pipe since 2003 , owning complete producing technology and abundant managing experience . Our raw material such as mother tube , round bar we use is from Chinese biggest and well known steel mill : Walsin , Yongxing etc . And We have adv......

ASTM A312 / ASME SA312 TP347 / 347H Austenitic Stainless Steel Pipe In Fluid And Gas

Stainless steel pipes, renowned for their corrosion resistance and durability, are versatile components used in various industries. Composed primarily of chromium and nickel, these pipes offer exceptional strength and longevity, ensuring reliability in challenging environments. Their adaptability ma......Get Quote

*Your email address will not be published. Required fields are marked.

English

English 中 文

中 文 Español

Español Português

Português Deutsch

Deutsch Türk

Türk Pусский

Pусский عربي

عربي 한국인

한국인 日本語

日本語