What is nickel alloy tube, pipe? Inconel alloy 600/601/625/825/C276 tube

What are the characteristics of nickel alloy pipes?

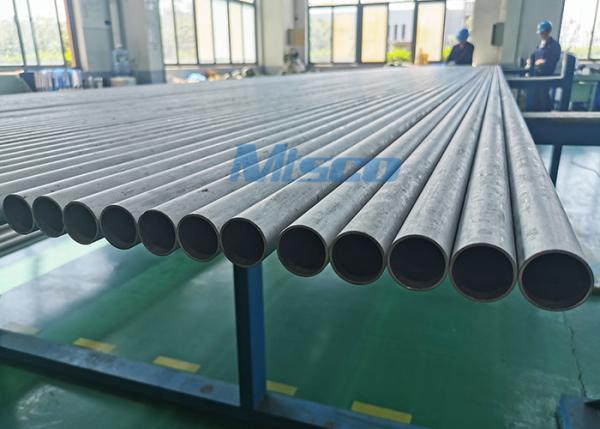

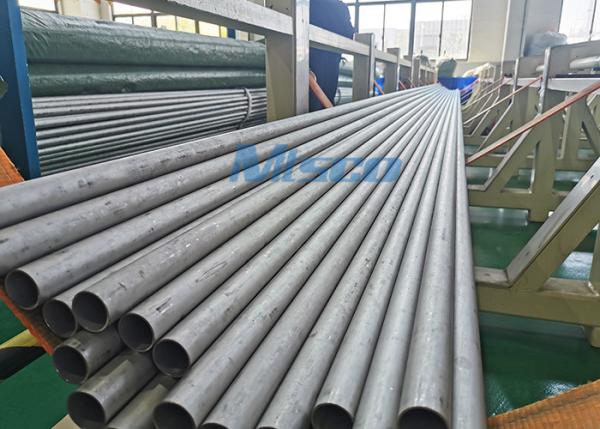

High-performance nickel alloy tubes for demanding applications in aerospace, oil and gas, and nuclear industries. MTSCO offers over 30 nickel alloy materials, ensuring reliability and high-temperature resistance.

Nickel-based alloys have excellent corrosion resistance, high-temperature strength, processing performance. It is an alloy composed of nickel as the main component, with the addition of chromium, iron, molybdenum and other elements. Based on the above characteristics, the high temperature resistance of nickel alloy tubes is particularly suitable for applications that need to withstand high temperatures and harsh environments. This feature makes nickel alloy tubes widely used in aerospace, oil and gas extraction, nuclear power, steam generators and other fields. In addition, nickel alloy tubes are resistant to stress corrosion cracking at high temperatures, ensuring the reliable operation of equipment piping systems. MTSCO has nearly 20 years of experience in the nickel alloy pipe industry and can provide more than 30 kinds of nickel alloy materials. The main ones are alloy 625, 825, 600, 601, 800, C276, C22, 200, etc., which have different properties and applications due to their different chemical compositions.

Alloy 625 Tube/Pipe

Inconel 600 tube is nickel-chromium-iron based solid solution strengthened alloy, with good high temperature corrosion and oxidation resistance, excellent hot and cold processing and welding properties, in 700 ℃ below the satisfactory thermal strength and high plasticity of these tubes are suitable for any traditional welding process with the same material or other metal welding.

Alloy 825 Tube/Pipe

Incoloy 825 alloy is rich in Cr, Mo, Cu, oxidizing and non-oxidizing acids have good resistance to full corrosion. Especially for sulfuric acid has very high corrosion resistance.

Alloy 600/601 Tube/Pipe

Alloy 600 and 601 due to the higher chromium content, the alloy has high strength and oxidation resistance at high temperatures, high temperature mechanical properties are significantly better than the general austenitic stainless steel with a low content of Ni, oxidation temperature can be as high as 1180 ℃.

Alloy C276 Tube/Pipe

Alloy C276 higher molybdenum, chromium content so that the alloy can resist the erosion of chloride ions, tungsten elements also further improve its corrosion resistance. This material is particularly suitable for use in high temperatures, inorganic and organic acids mixed with impurities (such as formic and acetic acid), and in seawater corrosive environments.

From raw materials to molding and processing quality control, MTSCO engineers strictly control each link to ensure the mechanical properties of each material, and to ensure that all kinds of nickel alloy tubes and pipes play their characteristics in different fields.

Related Products

English

English 中 文

中 文 Español

Español Português

Português Deutsch

Deutsch Türk

Türk Pусский

Pусский عربي

عربي 한국인

한국인 日本語

日本語