Why Tesla Chose Stainless Steel for the Cybertruck

Tesla's choice of stainless steel for the Cybertruck ensures exceptional strength, durability, and corrosion resistance, reducing maintenance needs and manufacturing costs.

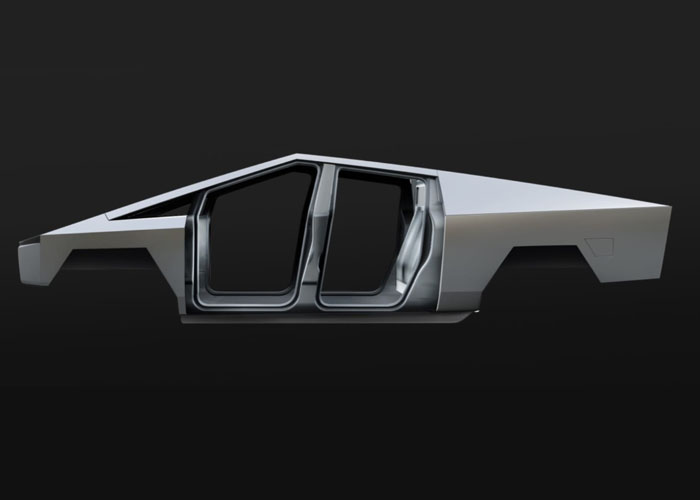

Tesla describes the new vehicle as "built with an exterior shell made for ultimate durability and passenger protection. Starting with a nearly impenetrable exoskeleton, every component is designed for superior strength and endurance, from Ultra-Hard 30X Cold-Rolled stainless-steel structural skin to Tesla armor glass."

Strength and Durability

Tesla's choice of stainless steel for the Cybertruck is primarily driven by the material's exceptional strength and durability. The vehicle uses a proprietary 30X cold-rolled stainless steel, which is known for its ultra-hard properties. This alloy, derived from the 300-series stainless steel, offers a significant increase in strength due to its microstructure, which includes both austenite and martensite formed through cold rolling. This enhances the Cybertruck’s ability to withstand impacts and resist dents, making it incredibly durable compared to conventional truck materials.

Corrosion Resistance

Another critical advantage of stainless steel is its resistance to corrosion. This property ensures that the Cybertruck remains resilient against harsh environmental conditions and reduces the need for frequent maintenance. The high corrosion resistance of stainless steel helps maintain the truck's aesthetic and structural integrity over a longer period, offering better longevity and lower maintenance costs for owners.

Cost Efficiency in Manufacturing

Using stainless steel also allows Tesla to use a unique manufacturing process that reduces costs.The flat and straight lines of the Cybertruck design mean that no stamping dies are needed to shape the body panels, or even blanking dies to form the billets. Instead, Tesla uses laser cutting and a simple folding press to form the body panels. This approach not only streamlines the manufacturing process, but also reduces the costs associated with tooling and machinery.

Design and Aesthetics

The decision to use stainless steel heavily influences the Cybertruck's distinctive design. The material’s hardness limits the ability to perform complex stamping, resulting in the truck's planar, futuristic appearance with flat panels and sharp lines. This design choice, while polarizing, underscores Tesla's commitment to innovation and breaking away from traditional automotive aesthetics.

Maintenance and Longevity

Tesla has also developed a non-directional finish for the Cybertruck's stainless steel, which allows owners to repair scratches themselves. This stainless steel exoskeleton will not only make the electric truck extremely durable, but it will also make maintenance a breeze thanks to its unique finish,and helps maintain its appearance over time. The non-directional finish ensures that any repairs blend seamlessly with the original surface, enhancing the vehicle’s overall longevity and maintaining its visual appeal.

In summary, Tesla's use of stainless steel for the Cybertruck is a strategic choice that leverages the material's strength, durability, corrosion resistance, and cost efficiency in manufacturing. This innovative approach not only enhances the vehicle's performance and longevity but also sets it apart in terms of design and maintenance.

English

English 中 文

中 文 Español

Español Português

Português Deutsch

Deutsch Türk

Türk Pусский

Pусский عربي

عربي 한국인

한국인 日本語

日本語