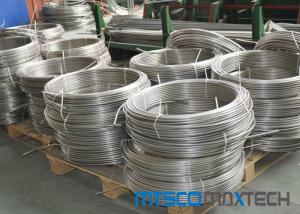

ASTM A249 TP304/304L/TP316/316L/316Ti Coiled Tubing

SSSCT11

Material: 304, 1.4301, X5CrNi18-10; 304H, S30415, 1.4948, S30409; 304L, 1.4306, S30403, 1.4307; 316L, 1.4401, 1.4404, 1.4435;

Get Quote

What is Coiled Tubing in Control Line?

Coiled tubing in control line, an industrial piping product used to regulate fluid temperature, pressure, and flow. It is usually composed of one or more tubes bent into a round or spiral shape.

Coiled tubing in control line, an industrial piping product used to regulate fluid temperature, pressure, and flow. It is usually composed of one or more tubes bent into a round or spiral shape, often installed near control valves, instruments or equipment. The main role of the coiled tubing has the following aspects:

Temperature control: the tubing can be used as a temperature sensor or temperature regulator connections, by changing the fluid flow rate and flow in the coiled tubing, to achieve precise control of the fluid temperature.

Pressure control: the tubing can be used as a pressure sensor or pressure regulator connection, by changing the pressure drop and resistance of the fluid in the coiled tubing, to achieve precise control of the fluid pressure.

Compensation of thermal expansion and contraction of piping: Coiled tubing can absorb the thermal expansion and contraction of piping during temperature changes to avoid damage.

Flow control: Coiled tubing can be used as a connection for flow sensors or flow regulators to achieve precise control of fluid flow by changing the cross-sectional area and length of the fluid inside the coiled tubing.

1.4404 / 1.4301 Size 9.53*20 BWG Stainelss Steel Coiled Tube For Oil And Gas

Chemical Composition

| C(max) | Si(max) | Mn(max) | P(max) | S(max) | Cr | Ni | Mo | Ti | |

| TP304/1.4301 | 0.080 | 1.00 | 2.00 | 0.045 | 0.030 | 18.0-20.0 | 8.0-10.5 | ||

| TP304L/1.4307 | 0.035 | 1.00 | 2.00 | 0.045 | 0.030 | 18.0-20.0 | 8.0-12.0 | ||

| TP304H/1.4948 | 0.04-0.10 | 1.00 | 2.00 | 0.045 | 0.030 | 18.0-20.0 | 8.0-12.0 | ||

| TP316/1.4401 | 0.080 | 1.00 | 2.00 | 0.045 | 0.030 | 16.0-18.0 | 11.0-14.0 | 2.0-3.0 | |

| TP316L/1.4404 | 0.035 | 1.00 | 2.00 | 0.045 | 0.030 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 | |

| TP316Ti/1.4571 | 0.080 | 1.00 | 2.00 | 0.045 | 0.030 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 | 0.7>5x(C+N) |

| TP321/1.4541 | 0.080 | 1.00 | 2.00 | 0.045 | 0.030 | 17.0-19.0 | 9.0-12.0 | 0.7>5x(C+N) | |

| TP317L/1.4449 | 0.080 | 1.00 | 2.00 | 0.045 | 0.030 | 18.0-20.0 | 11.0-14.0 | 3.0-4.0 | |

| TP347H/1.4912 | 0.04-0.10 | 1.00 | 2.00 | 0.045 | 0.030 | 17.0-19.0 | 9.0-13.0 | ||

| TP309S/1.4833 | 0.080 | 1.00 | 2.00 | 0.045 | 0.030 | 22.0-24.0 | 12.0-15.0 | 0.75 | |

| TP310S/1.4845 | 0.080 | 1.00 | 2.00 | 0.045 | 0.030 | 24.0-26.0 | 19.0-22.0 | 0.75 |

Where the coiled tubing used ?

1 . Control tubing in oil and gas well

2 . Instrument tubing

3 . Chemicl injection tubing line

4 . Pre-insulated tubing

5 . Electric heating or steam heating tubing line

6 . Hater tubing line

| Birmingham Wire Gauge BWG | |||||

| Wall Thickness | Wall Thickness | ||||

| BWG | IN | MM | BWG | IN | MM |

| 0 | 0.340 | 8.64 | 19 | 0.042 | 1.07 |

| 1 | 0.300 | 7.62 | 20 | 0.035 | 0.89 |

| 2 | 0.284 | 7.21 | 21 | 0.032 | 0.81 |

| 3 | 0.259 | 6.58 | 22 | 0.028 | 0.71 |

| 4 | 0.238 | 6.05 | 23 | 0.025 | 0.64 |

| 5 | 0.220 | 5.59 | 24 | 0.022 | 0.56 |

| 6 | 0.203 | 5.16 | 25 | 0.020 | 0.51 |

| 7 | 0.180 | 4.57 | 26 | 0.018 | 0.46 |

| 8 | 0.165 | 4.19 | 27 | 0.016 | 0.41 |

| 9 | 0.148 | 3.76 | 28 | 0.014 | 0.36 |

| 10 | 0.134 | 3.40 | 29 | 0.013 | 0.33 |

| 11 | 0.120 | 3.05 | 30 | 0.012 | 0.30 |

| 12 | 0.109 | 2.77 | 31 | 0.010 | 0.25 |

| 13 | 0.095 | 2.41 | 32 | 0.009 | 0.23 |

| 14 | 0.083 | 2.11 | 33 | 0.008 | 0.20 |

| 15 | 0.072 | 1.83 | 34 | 0.007 | 0.18 |

| 16 | 0.065 | 1.65 | 35 | 0.005 | 0.13 |

| 17 | 0.058 | 1.47 | 36 | 0.004 | 0.10 |

| 18 | 0.049 | 1.24 |

MTSCO is a leading manufacturer who is specialized in seamless coiled tubing produce . Stainless steel seamless coiled tubing final surface is bright annealed. According to standard very strictly, tubes which produced by us always have correct OD and WT tolerance. They are very popular in military, semiconductor, pharmaceutical biotechnology, precision instruments, hydraulic parts, chemicals industry, boilers and heat exchangers, aerospace industry, automotive industry, electronics, petroleum exploration, precision machinery, rail transportation, shipbuilding plants, air-conditioning industry, solar industry, water heater industry etc. They can be used in many others industries also .

VIP SERVICE

VR (Virtual) Mill Introduction

Professional Remote Technical Guidanceion

Accept Third-party Inspection

Door to Door Shipment

Get QuoteRelated Products: Coiled Tubing, Control Line: Welded / Seamless Coiled Tubing

20BWG 0.89mm Wall Thickness ( WT ) Stainless Steel Coiled Tubing ASTM A213 Standard

MTSCO is a leading manufacturer who is specialized in seamless coiled tubing produce . Stainless steel seamless coiled tubing final surface is bright annealed. According to standard very strictly, tubes which produced by us always have correct OD and WT tolerance. They are very popular in military, ......

Sheathed multicore tubing & single core tubing

Mtsco's multicore tubes are used for pneumatic and hydraulic remote control, measuring and monitoring systems. materials are ASTM TP316/ 316L, TP304/304L The multicore tube consists of one to nine stainless steel tubes laid up spirally inside an extruded outer PVC sheath. For easy identification and......

S31803 ASTM A789 / A790 Duplex Steel Coiled Tube For Chemical Industry

Inspection & Test 1 .100 % PMI , Spectro Chemical Aanlysis Test for Raw Material 2 .100 % Dimension & Visual Examination 3 . Mechanical Properties Test Include Tension Test,Flaring Test ( For Seamless tube / pipe ) / Flange Test ( For Welded Pipe & Tube ) , Hardness Test , Reversed Flatteni......

English

English 中 文

中 文 Español

Español Português

Português Deutsch

Deutsch Türk

Türk Pусский

Pусский عربي

عربي 한국인

한국인 日本語

日本語