Alloy 601 UNS N06601 Nickel Alloy Tube

SSNAT05

Price: From $31000-50000USD/TON

Material: Alloy 600, UNSN06600;

Get Quote

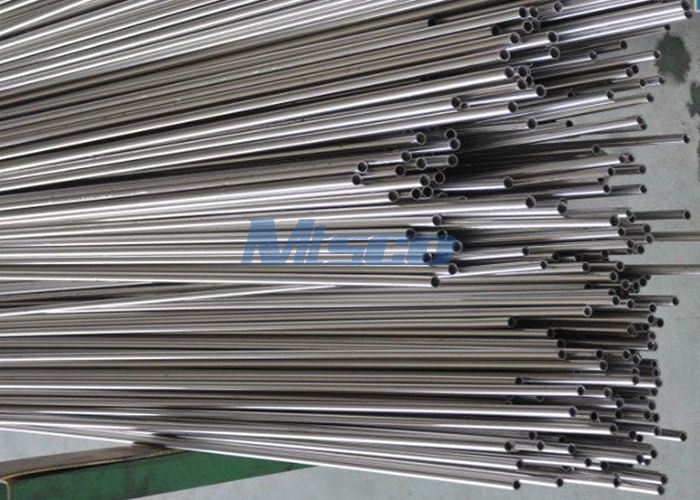

Alloy 600 / 601 UNS N06600/ N06601 Nickel Alloy Tube

1. Grade : Alloy625 / N06625 ,Alloy 600 / N06600 , Alloy 601 / N06601 , Alloy 718 / N07718 ,Alloy C276 / N10276 , Alloy 800 / N08800 , Alloy 825 / N08825 , Alloy 400 / N04400 ; etc

2 . OD ( Outer Diameter ) : 3.18mm to 101.60mm

3 . WT ( Wall Thickness ) : 0.50mm to 20.00mm

4 . Length : As customer's requirement

5 . Standard : ASTM B163; ASTM B167; ASTM B444; ASTM B622 etc

6 . Technology : Cold Drawn / Cold Rolled

Chemical composition:

| Grade | C max | Si max | Mn max | P max | S max | Cr | Ni | Mo | Ti | N max | Cu max | Nb | Al max | Co max | Zr | Fe max | Tu | Va |

| Alloy 600/N06600 | 0 | 1 | 1 | - | 0 | 14-17 | ≥72 | - | - | - | 1 | - | - | - | - | 6-10 | - | - |

| Alloy 601/N06601 | 0 | 1 | 2 | - | 0 | 21.0-25.0 | 58-63 | - | - | - | 1 | - | 1.0-1.7 | - | - | - | - | - |

| Alloy 625/N06625 | 0 | 1 | 1 | 0 | 0 | 20-23 | ≥58 | 8-10 | <0.4 | - | - | 3.15-4.15 | ≤0.4 | - | - | 5.00 remainder | - | - |

Physical properties:

| Grade | Physical Property | |||

| Y.S | T.S | EL. | HB | |

| Alloy 600/N06600 | 205-345 | 550-690 | 35-55 | ≤185 |

| Alloy 601/N06601 | 240-300 | 600-650 | 30-35 | ≤220 |

| Alloy 625/N06625 | ≥345 | ≥760 | ≥30 | ≤220 |

Features:

High Temperature Resistance: Alloy 601 tubing is capable of maintaining stable performance under extreme high temperature conditions, and its high temperature resistance makes it ideal for use in a variety of high temperature environments.

Corrosion resistance: Nickel alloy tubing Alloy 601 shows excellent resistance to a wide range of corrosive media, including acids, alkalis, oxides, etc., resulting in excellent durability in corrosive environments.

Excellent Mechanical Properties: Alloy 601 tubes have good mechanical properties, including high strength, excellent toughness and fatigue resistance, which can meet a variety of engineering needs.

Good Thermal Expansion Properties: Alloy 601 has good thermal expansion properties at elevated temperatures, which reduces stress and distortion due to temperature changes.

Ease of processing: this nickel alloy tube is easy to process into various shapes and sizes, suitable for a variety of processes to meet the needs of different applications.

Test :

1 . NTD(Ultrasonic test, Eddy Current test)

2 . Mechanical Test(Tension Test, Flaring Test, Flattening Test, Hardness Test, Hydraulic test)

3 . Metal Test(Metallographic Analysis, Impact Test-High/low temperature)

4 . Chemical Analysis(Photoelectric Emission Spectroscopic)

VIP SERVICE

VR (Virtual) Mill Introduction

Professional Remote Technical Guidanceion

Accept Third-party Inspection

Door to Door Shipment

Get QuoteRelated Products: Seamless Tube: Bright Annealed Polished Tube

Structure and machining pipe Casing Tube

High-Tech This is the type of drawing used for the highest quality output. The outside and insida diameters of the mother tube are worked at the same time. A floating plug made of high grade tool steel with a polished surface is located inside the mother tube. As the tube is drawn through the di......

TP316 / 316L ASTM A269 / ASME SA269 Stainless Steel Sanitary Tube For Medical Indusry

Grade: TP 304; TP304H; TP304L; TP316; TP316L; TP 321;TP321H; TP317L; TP310S; TP347H Standard: ASTM A213, ASTM A 269, ASTM A 270,EN10216-5; ASTM B 622;ASTM B516;ASTM A789, etc Size OD:3.18-101.6mm WT:0.5-20mm Length:Max.12M Advantage: Superior surface finish ,better mechanical property; ......

TP316 / 316L Stainless Steel Seamless Hydraulic Tube, ASTM A269

MTSCO is a leading manufacturer who is specialized in stainless steel seamless pipes , bright annealed tubes , seamless coiled tubing etc . MTSCO has the most advanced producing and testing equipment . We can totally satisfy your requirement . Stainless steel seamless bright annealed tube’s f......

English

English 中 文

中 文 Español

Español Português

Português Deutsch

Deutsch Türk

Türk Pусский

Pусский عربي

عربي 한국인

한국인 日本語

日本語