TP304/304L Welded Stainless Steel Coiled Tubing

SSMCT03

Material: 304, 1.4301, X5CrNi18-10; 304H, S30415, 1.4948, S30409; 304L, 1.4306, S30403, 1.4307;

Get Quote

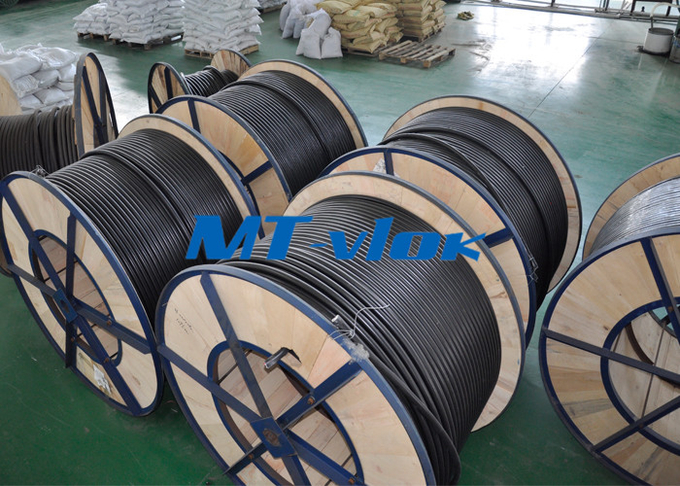

Coiled tubing

Coiled tubing in control line, an industrial piping product used to regulate fluid temperature, pressure, and flow. It is usually composed of one or more tubes bent into a round or spiral shape, often installed near control valves, instruments or equipment. The main role of the coiled tubing has the following aspects:

Temperature control: the tubing can be used as a temperature sensor or temperature regulator connections, by changing the fluid flow rate and flow in the coiled tubing, to achieve precise control of the fluid temperature.

Pressure control: the tubing can be used as a pressure sensor or pressure regulator connection, by changing the pressure drop and resistance of the fluid in the coiled tubing, to achieve precise control of the fluid pressure.

Compensation of thermal expansion and contraction of piping: Coiled tubing can absorb the thermal expansion and contraction of piping during temperature changes to avoid damage.

Flow control: Coiled tubing can be used as a connection for flow sensors or flow regulators to achieve precise control of fluid flow by changing the cross-sectional area and length of the fluid inside the coiled tubing.

TP304 / 304L Welded Stainless Steel Coiled Tubing For Multi-core Tube

The multi-core tube consists of one to nine stainless steel tubes laid up spirally inside an extruded outer PVC sheath. For easy identification and protection purposes each individual tube is PVC sheathed in a different color. The extruded outer sheath is made of oil and seawater resistant, weatherproof, flame retardant, corrosion and acid resistant PVC. The multi-core tube (outer sheath) is continuously marked at every one meter throughout the entire length for easy installation. Heat shrinkable products provide complete water sealing, abrasion and corrosion protection under all conditions.

Where the multi-core coiled tubing used ?

Mtsco' s multi-core tubes are used for pneumatic and hydraulic remote control, measuring and monitoring systems. materials are ASTM TP316/ 316L, TP304/304L.

| Ordering code number | Tube size (O.D x Thickness x Core) | Overall Diameter (.mm) | Sheath Thickness (.mm) | Bundle Weight (kg/M) | Max Pressure (Bar) |

| HTD-1 | 6×1.0×1 | 8 | 1.0 | 0.15 | Working:180Bar

Test:270Bar |

| HTD-2 | 6×1.0×2 | 20 | 2.0 | 0.60 | |

| HTD-3 | 6×1.0×3 | 21 | 2.0 | 0.75 | |

| HTD-4 | 6×1.0×4 | 24 | 2.0 | 0.82 | |

| HTD-5 | 6×1.0×5 | 25 | 2.0 | 0.90 | |

| HTD-6 | 6×1.0×6 | 27 | 2.0 | 1.04 | |

| HTD-7 | 6×1.0×7 | 27 | 2.0 | 1.15 | |

| HTD-8 | 6×1.0×8 | 32 | 2.2 | 1.40 | |

| HTD-9 | 8×1.0×1 | 10 | 1.0 | 0.28 | |

| HTD-10 | 8×1.0×2 | 24 | 1.8 | 0.89 | |

| HTD-11 | 8×1.0×3 | 26 | 2.0 | 1.12 | |

| HTD-12 | 8×1.0×4 | 28 | 2.0 | 1.33 | |

| HTD-13 | 8×1.0×5 | 31 | 2.0 | 1.67 | |

| HTD-14 | 8×1.0×6 | 34 | 2.0 | 2.00 | |

| HTD-15 | 8×1.0×7 | 34 | 2.0 | 2.15 | |

| HTD-16 | 8×1.0×8 | 40 | 2.2 | 2.60 | |

| HTD-17 | 10×1.0×1 | 13 | 1.0 | 0.34 | |

| HTD-18 | 10×1.0×2 | 28 | 1.8 | 1.18 | |

| HTD-19 | 10×1.0×3 | 31 | 2.0 | 1.60 | |

| HTD-20 | 10×1.0×4 | 34 | 2.0 | 1.97 | |

| HTD-21 | 10×1.0×5 | 37 | 2.0 | 2.20 | |

| HTD-22 | 10×1.0×6 | 40 | 2.0 | 2.40 | |

| HTD-23 | 10×1.0×7 | 40 | 2.0 | 2.52 | |

| HTD-24 | 10×1.0×8 | 48 | 2.5 | 3.20 | |

| HTD-25 | 12×1.0×1 | 14 | 1.0 | 0.41 | |

| HTD-26 | 12×1.0×2 | 34 | 2.0 | 1.35 | |

| HTD-27 | 12×1.0×3 | 36 | 2.0 | 1.96 | |

| HTD-28 | 12×1.0×4 | 39 | 2.0 | 2.37 | |

| HTD-29 | 12×1.0×5 | 43 | 2.0 | 2.70 | |

| HTD-30 | 12×1.0×6 | 47 | 2.0 | 3.00 | |

| HTD-31 | 12×1.0×7 | 47 | 2.0 | 3.14 | |

| HTD-32 | 12×1.0×8 | 55 | 2.5 | 3.90 |

| ASTM A269 Standard | |

| Elements | TP304 ( S30400 ) |

| (C) Carbon, max : | 0.08 |

| (Mn) Manganese, max : | 2 |

| (P) Phosphorus, max : | 0.045 |

| (S) Sulfur, max : | 0.03 |

| (Si) Silicon, max : | 1 |

| (Ni) Nickel : | 8.0 - 11.0 |

| (Cr) Chromium : | 18.0 - 20.0 |

| (Mo) Molybdenum : | … |

| (Fe) Iron : | … |

| (Cu) Copper : | … |

| (N) Nitrogen : | … |

VIP SERVICE

VR (Virtual) Mill Introduction

Professional Remote Technical Guidanceion

Accept Third-party Inspection

Door to Door Shipment

Get QuoteRelated Products: Coiled Tubing, Control Line: Encapsulated Tube

ASTM B704 Alloy 825 Multi-Core Encapsulated Control Line 1500psi

MTSCO has been supplying industrial tubing to the oil and gas industry for more than a decade. In recent years, we have continued to make breakthroughs in the field of coiled tubing, downhole control lines, and chemical injection control lines. Our coiled tubing has been successfully used in certain......

English

English 中 文

中 文 Español

Español Português

Português Deutsch

Deutsch Türk

Türk Pусский

Pусский عربي

عربي 한국인

한국인 日本語

日本語