A General Engineering Alloy-Nickel Alloy 825

Product Characteristics 1. Good stress corrosion cracking resistance 2. Good resistance to pitting corrosion and crevice corrosion 3. Very good oxidation resistance and non-oxidizing thermal acidity 4. good mechanical properties at room temperature and high temperature up to 550℃ 5. Certified to manufacture pressure vessels at temperatures up to 450℃ |  |

Corrosion Resistance

Nickel Alloy 825 is a general engineering alloy. It has acid and alkali corrosion resistance in oxidation and reduction environment. High nickel composition makes the alloy have effective stress corrosion resistance and cracking resistance. It has good corrosion resistance in various media, such as sulfuric acid, phosphoric acid, nitric acid and organic acid, and alkali metals such as sodium hydroxide, potassium hydroxide and hydrochloric acid solution. The high comprehensive performance of incoloy 825 is reflected in the Nuclear Combustion dissolver with various corrosive media, such as sulfuric acid, nitric acid and sodium hydroxide are treated in the same equipment

Nickel Alloy 825 Chemical Composition:

% | Ni | Fe | Cr | C | Mn | Si | S | Mo | Cu | Ti | Al |

min | 38 | 22 | 19.5 | 2.5 | 1.5 | 0.6 | |||||

max | 46 | 23.5 | 0.05 | 1 | 0.5 | 0.03 | 3.5 | 3 | 1.2 | 0.2 |

Application:

Alloy 825 is widely used in various industrial fields where the service temperature does not exceed 550 ℃

Typical application:

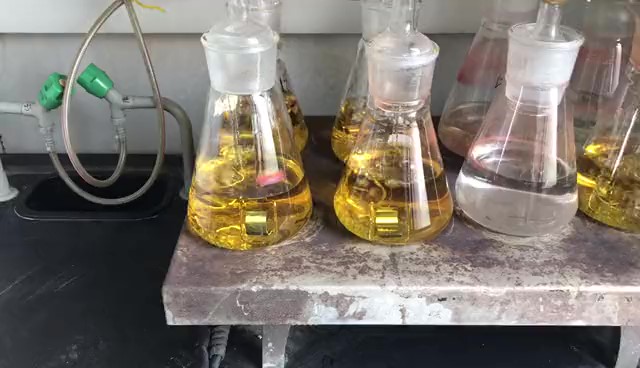

1. Heating pipes, containers, baskets and chains for sulfuric acid pickling plant.

2 seawater cooling heat exchanger, marine product pipeline system and acid gas environment pipeline.

3. Heat exchanger, evaporator, washing and impregnation pipe in phosphoric acid production.

4. Air heat exchanger in petroleum refining

5. Food Engineering

6. Chemical process

7. Flame retardant alloys for high pressure oxygen applications

Alloy 825 Welding

N08825 is suitable for welding with the same material or other metals by any conventional welding process, such as tungsten electrode inert gas shielded welding, plasma arc welding, manual sub-arc welding, metal electrode inert gas shielded welding, molten electrode inert gas shielded welding, of which pulsed arc welding is the preferred solution. When using manual arc welding, it is recommended to use (Ar + He + H2 + CO2) a mixture of multiple ingredients of shielding gas. welding of N08825 must be carried out in the annealed state and cleaned with a stainless steel wire brush to remove stains, dust and various marks. When welding the root of the weld, in order to get the best quality of the root weld, the operation must be very careful (argon 99.99) so that the weld does not produce oxides after the root is welded. The color produced in the heat affected zone of the weld is to be removed with a stainless steel brush while the weld area is not cooled.

English

English 中 文

中 文 Español

Español Português

Português Deutsch

Deutsch Türk

Türk Pусский

Pусский عربي

عربي 한국인

한국인 日本語

日本語