How to treat blackened surfaces on stainless steel polished tubes?

High-quality stainless steel polished tubes rarely show surface blackening. If the surface is blackened during long-term use, the reason is that the air action causes the stainless steel polished tube to produce a layer of oxide film.This oxide film can protect the metal inside the stainless steel from further oxidation. Under normal circumstances, oxide film does not need to be wiped off because it does not damage the tube itself. Different stainless steel polished tubes have different colors of oxide films due to material element content, but they all have no effect on the tube itself. If you think the surface of the product is not beautiful, you can do a polishing treatment.

If the surface of the stainless steel polished tube is blackened after welding, this may be due to insufficient purity of the welding gas or high-temperature oxidation. The following three methods will teach you how to solve this problem:

1. When welding, increase the purity of the argon gas. The tube's outer surface is much brighter with pure argon welding than with regular argon welding.

2. When welding polished stainless steel tubes, the inside of the tube (the back of the weld) must be protected by argon. If no protection is given, the high temperature during welding will cause the back weld layer to oxidize. This may form slag-like defects, which will affect the quality of the weld. Therefore, argon protection can effectively prevent oxidation and ensure that the weld surface is smooth and defect-free.

3. If it is difficult to use argon protection, a special welding back protective agent can be used as an alternative. Evenly apply a protective agent with a thickness of about 1 mm on the back of the weld. The heat from front welding makes the protective agent form a shielding layer, blocking air and preventing weld back oxidation. This method can not only avoid the complicated operation of traditional argon protection, but also ensure the quality of the weld and prevent oxidation defects.

If the weld marks of the stainless steel polished tube are found to be black, we can use Pickling & Passivation Paste to clean it. This can help corrode the black oxide layer on the surface of the stainless steel polished tube, and rinse it with clean water.

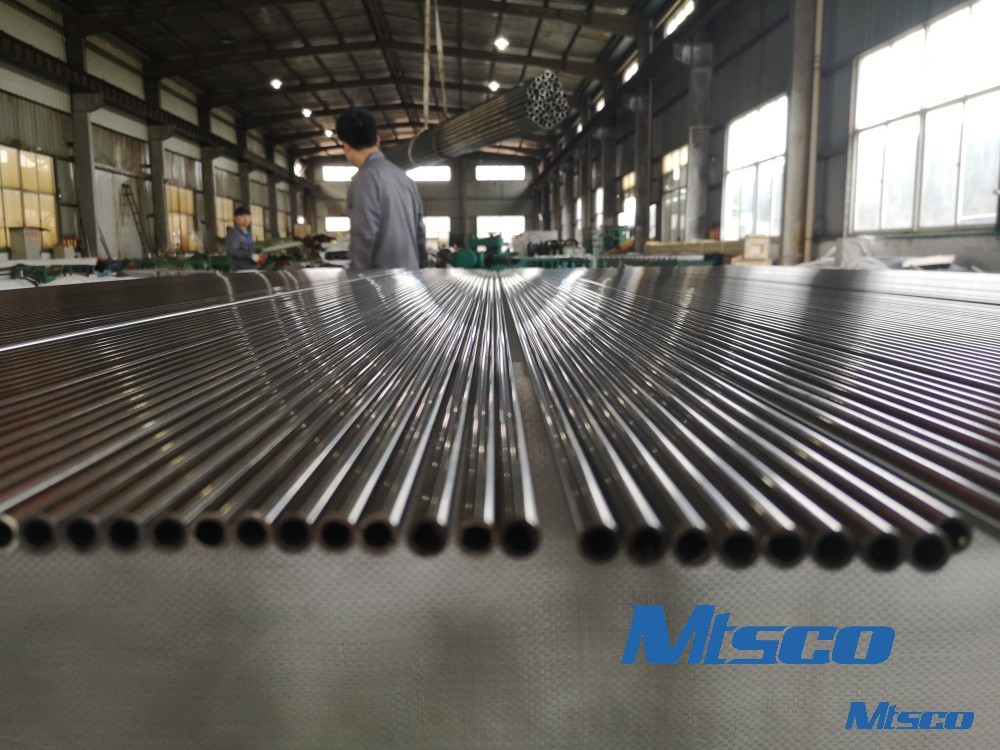

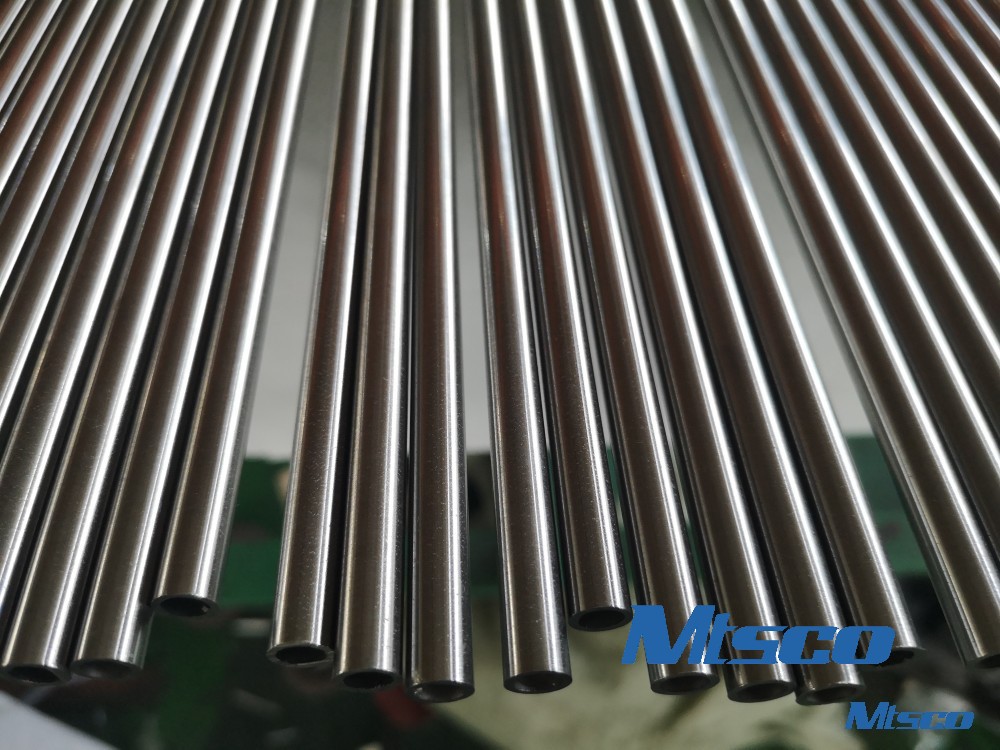

MTSCO dedicated to providing high-quality yet cost-effective products and professional services. We specialize in manufacturing stainless steel polished tubes, seamless pipes, welded pipes, BA/AP polished tubes, pipe fittings, flanges, and forgings. For any inquiries, please feel free to contact us - we're ready to serve your needs.

English

English 中 文

中 文 Español

Español Português

Português Deutsch

Deutsch Türk

Türk Pусский

Pусский عربي

عربي 한국인

한국인 日本語

日本語