Alloy 625, UNSN06625, Nickel Alloy Steel Pipe/Tube, Flanges, Fittings

Alloy 625 (UNS N06625) | |||||||||

Summary | A nickel-chromium-molybdenum alloy with an addition of niobium that acts with the molybdenum to stiffen the alloy's matrix and thereby provide high strength without a strengthening heat treatment. The alloy resists a wide range of severely corrosive environments and is especially resistant to pitting and crevice corrosion. Used in chemical processing, aerospace and marine engineering, pollution-control equipment, and nuclear reactors. | ||||||||

Standard Product Forms | Pipe, tube, sheet, strip, plate, round bar, flat bar, forging stock, hexagon and wire. | ||||||||

Chemical Composition Wt,% |

| Min | Max. |

| Min. | Max. |

| Min. | Max. |

Ni | 58.0 |

| Cu |

|

| C |

| 0.1 | |

Cr | 20.0 | 23.0 | Co |

| 1.0 | Si |

| 0.5 | |

Fe |

| 5.0 | Al |

| 0.4 | P |

| 0.015 | |

Mo | 8.0 | 10 | Ti |

| 0.4 | S |

| 0.015 | |

Nb | 3.15 | 4.15 | Mn |

| 0.5 | N |

|

| |

Physical Constants | Density,g/ | ||||||||

Melting Range,℃ 1290-1350 | |||||||||

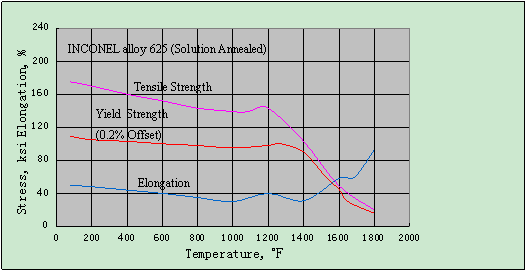

Typical Mechanical Properties | (Solution Annealed) (1000h) Rupture Strength (1000h) ksi Mpa 1200℉/650℃ 52 360 1400℉/760℃ 23 160 1600℉/870℃ 72 50 1800℉/980℃ 26 18 | ||||||||

|

Microstructure

Alloy 625 is a solid-solution matrix-stiffened face-centered-cubic alloy.

Characters

Due to its low carton content and stabilizing heat treatment, Inconel 625 show little tendency to sensitization even after 50 hour at temperatures in the range 650~450℃.

The alloy is supplied in the soft-annealed condition for applications involving wet corrosion (Alloy 625, grade 1), and is approved by TUV for pressure vessels in the temperature range -196 to 450℃.

For high-temperature applications, above approx. 600℃ ,where high strength and resistance to creep and rupture are required, a solution-annealed version (Alloy 625,grade 2) with a higher carbon content is normally employed and available on request in some products forms.

Outstanding resistance to pitting, crevice corrosion, and intergranular attack;

Almost complete freedom from chloride-induced stress-corrosion cracking;

Good resistance to mineral acids, such as nitric, phosphoric, sulphuric and hydrochloric acids;

Good resistance to alkalis and organic acids;

Good mechanical properties.

Corrosion Resistance

The high alloy content of alloy 625 enable it to withstand a wide variety of severe corrosion environment. In mild environments such as the atmosphere, fresh and sea water, neutral salts, and alkaline media there is almost no attack. In more severe corrosion environment the combination of nickel and chromium provides resistance to oxidizing chemical, whereas the high nickel and molybdenum contents supply resistance to nonoxidizing against sensitization during welding, thereby preventing subsequent intergranular cracking. Also, the high nickel content provides from chloride ion-stress-corrosion cracking.

Applications

The soft-annealed version of Alloy 625 (grade 1) is preferred for applications in the chemical process industry, in marine engineering and in pollution control equipment for environment protection. Typical applications are:

1. Superphosphoric acid production equipment;

2. Nuclear wasts reprocessing equipment;

3. Sour gas production tubes;

4. Piping systems and sheathing of risers in oil exploration;

5. Offshore industry and marine equipment;

6. Flue gas scrubber and damper components;

7. Chimney linings.

For high-temperature application, up to approximately 1000℃, the solution-annealed version of Alloy 625 (grade 2) can be used in accordance to the ASME code for pressure vessels. Typical application are:

1. Components in waste gas system and waste gas cleaning plants exposed to higher temperatures;

2. Flare stacks in refineries and offshore platforms;

3. Recuperator and compensators;

4. Submarine diesel engine exhaust systems;

5. Superheater tubes in wastes incineration plants.

English

English 中 文

中 文 Español

Español Português

Português Deutsch

Deutsch Türk

Türk Pусский

Pусский عربي

عربي 한국인

한국인 日本語

日本語