Seamless Pipe

35 Years Seamless Pipe Manufacturing Experience,Meet Your Various Needs.

Seamless pipe is a high-quality pipe material with a seamless structure, which has good corrosion resistance and high strength. It is widely used in various industries, including pipeline transportation systems in fields such as petroleum, chemical, pharmaceutical, and food.

Seamless pipe can be used to withstand high pressure and high temperature working environments, and their seamless characteristics make them excellent in fluid transmission and structural applications. They are considered a reliable and economical pipeline solution.

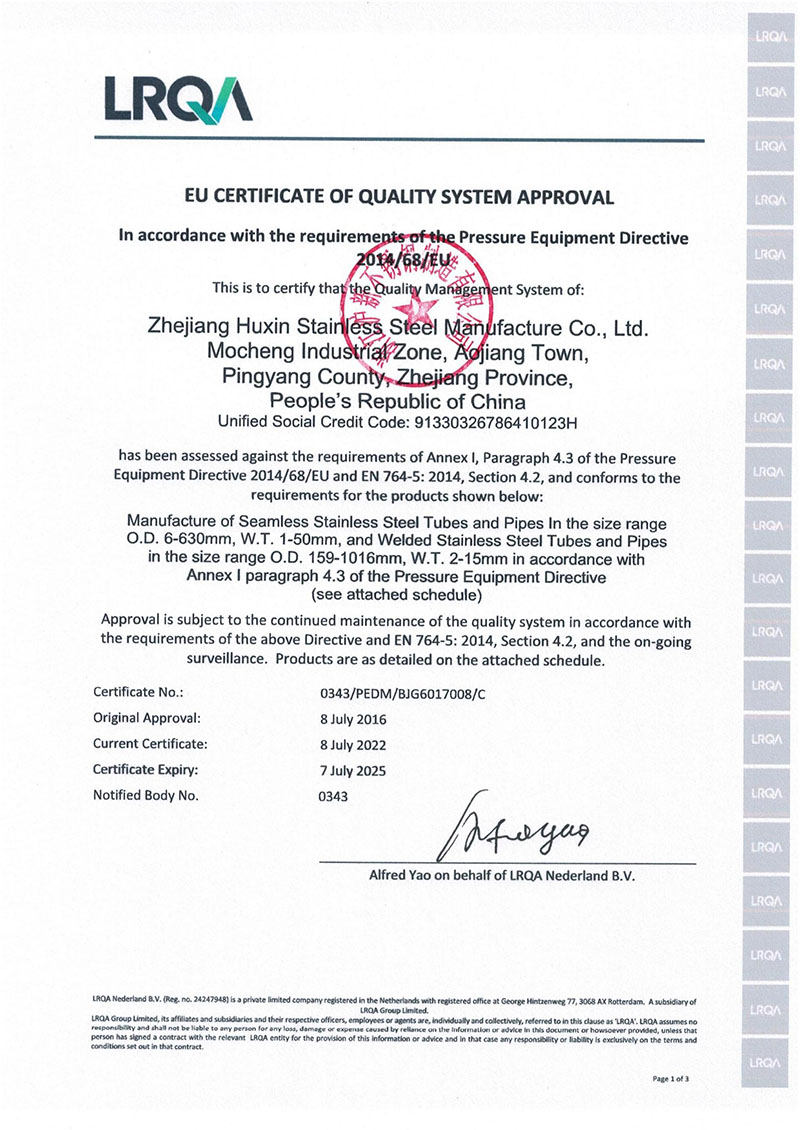

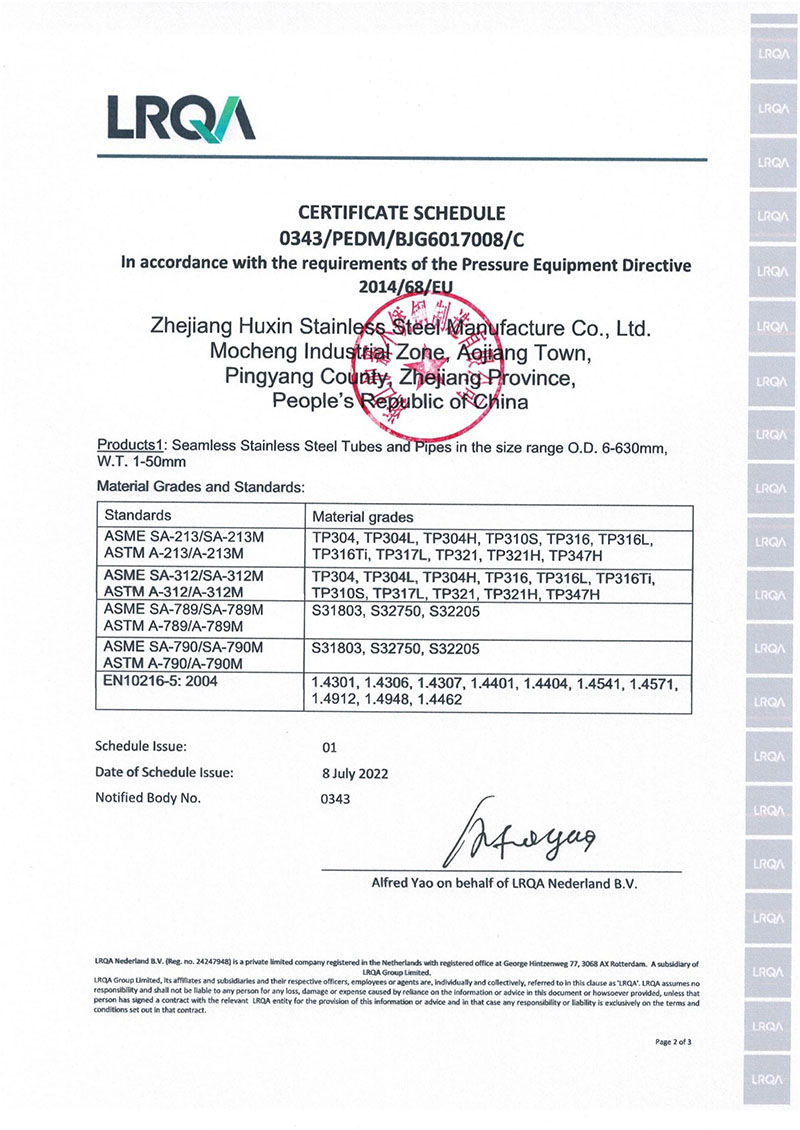

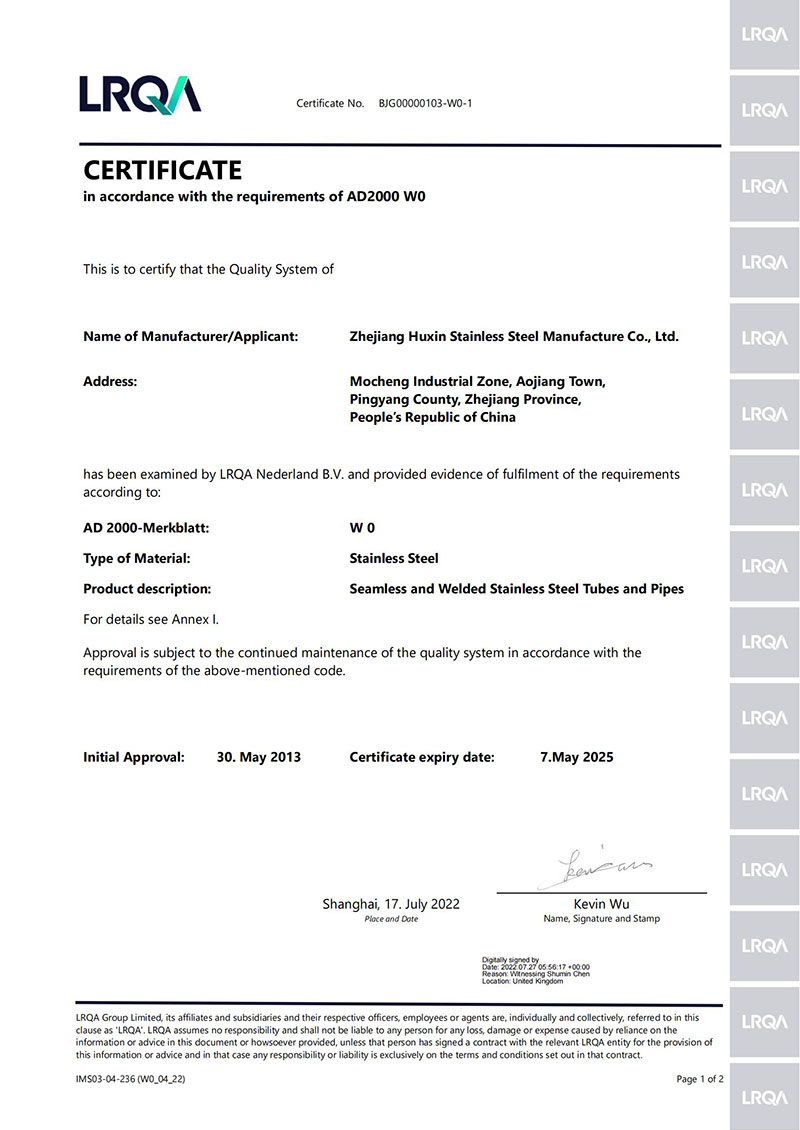

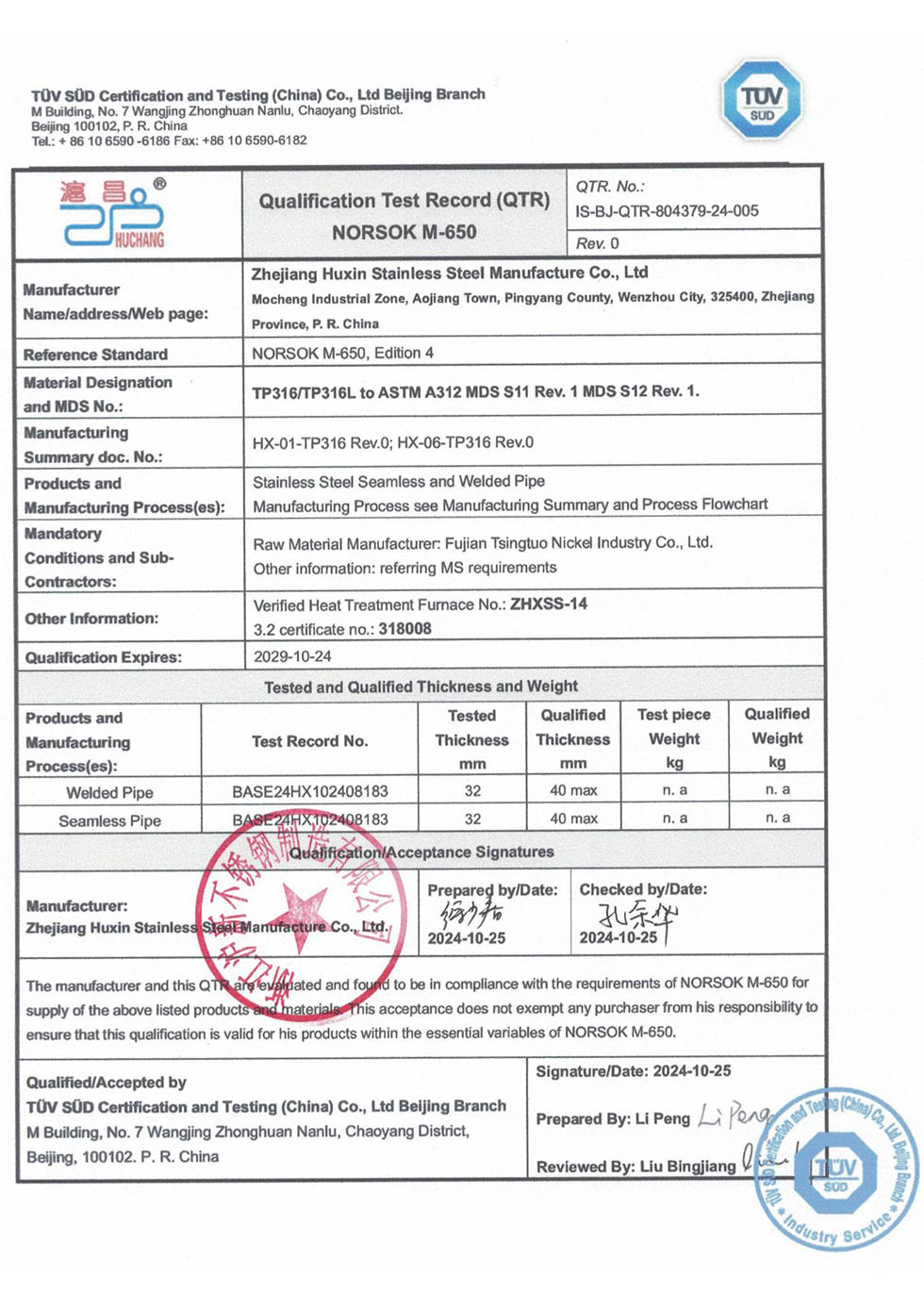

MTSCO seamless pipes have a highly guaranteed supply chain. MTSCO has invested in a factory - HUXIN PIPE, which has 35 years pipe manufacturing experience. MTSCO has reached a high strategic partnership with Huxin pipe, becoming the only international sales center of Huxin. We can produce seamless pipes of varying lengths, including extended ones like 18 meters and 25 meters.

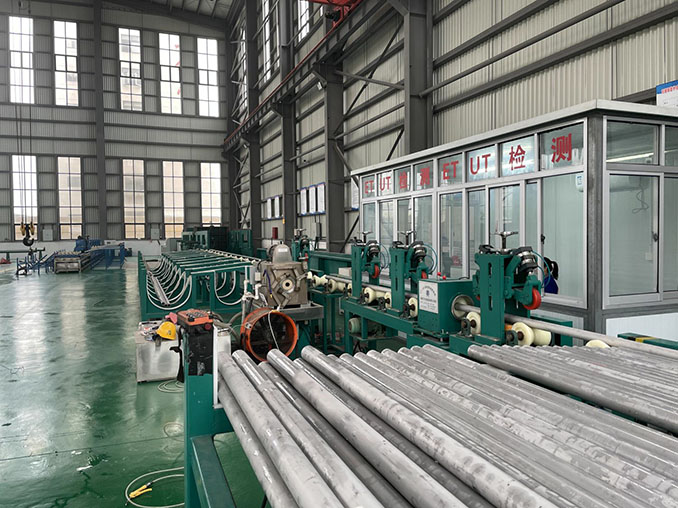

Huxin is fully equipped with production, inspection, and laboratory equipment like cold rolling machines, annealing furnaces, pickling pools, and integrated eddy current ultrasonic systems.

These pipes from MTSCO have found extensive application in industrial constructions across diverse global regions. Our customers' satisfaction resonates through their feedback and appreciation, fostering numerous enduring and deep-seated partnerships.

.

VIP SERVICE

VR (Virtual) Mill Introduction

Professional Remote Technical Guidanceion

Accept Third-party Inspection

Door to Door Shipment

Get QuoteSpecifications of Seamless Pipe

Standard |

ASTM-A312 |

Materials |

Austenitic: 300 Series... |

Specifications |

Outer Diameter: 8mm-711mm |

Products

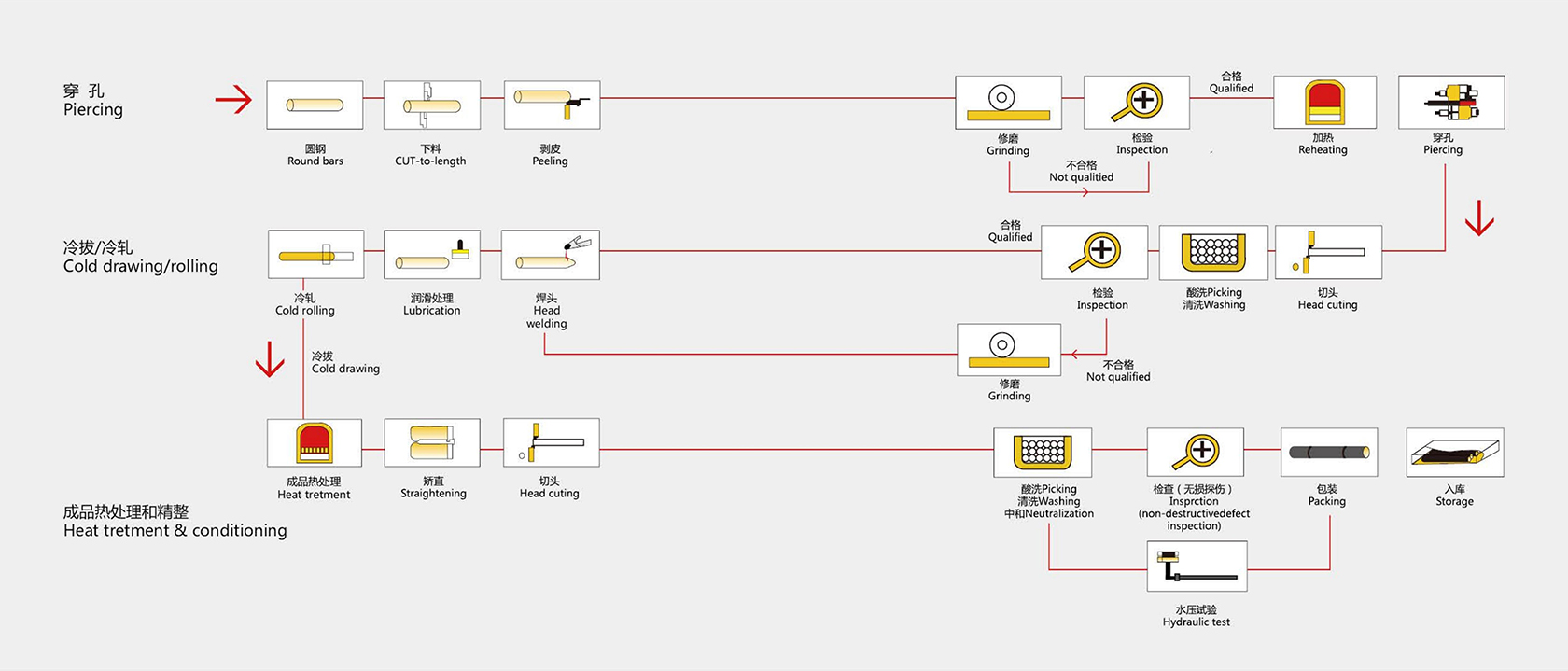

Seamless Pipe Production Process

Quality Control of MTSCO Seamless Pipe

1. Quality Control of Raw Materials

Warning: Undefined array key 61 in /home2/j1304181/public_html/prod_3.php on line 189

.

2. Process Control During Production

Each process is equipped with advanced production equipment, and is supervised byexperienced engineers and technicians. Each link is supervised by professional qc inspectorsand photographed for archiving. The entire process uses process cards to ensure accuracy andtraceability.

3. Quality Control Before Shipment

MTSCO has professional QC team to conduct a series of inspections and experiments on thePipes, including routine appearance, PMI, size, quantity, and other inspections. At the sametime, we also conducts mechanical testing, hardness testing, UT, ET, HT and other tests. Inaddition, we also accept third-party inspection, such as SGS, TUV, and BV.

Before shipping, we use appropriate and safe packaging methods and take measures such ascontainer reinforcement to ensure that your goods are delivered to you in good condition.

CNC Continuous Roller Bottom Annealing Furnace

Eddy Current Ultrasonic Integrated Machine

60 120 Rolling Machine

Project Cases

| Year | Project | End User/ EPC | Site | Material | Products | QTY(KGS) |

| 2022-2023 | KUG PROJECT | TATNEFT | RUSSIA | N08825 | SMLS PIPE | 150,000 |

| 2022 | CHUNBO TANK | DONGIL | KOREA | N06022 | PLATE/PIPE/TUBE | 70,000 |

| 2020-2021 | FGD SYSTEM PACKAGE FOR MOUDA STPP, STAGE II(2X660MW) | MHPS/NTPC | INDIA | N10276 | PIPE/ FITTING/ FLANGE | 17,000 |

| 2017-2020 | PRACTICUM ENGINEERING CO., LTD | DOOSAN | THAILAND | 304L; 316L; 310S; UNS N06600 | SMLS TUBE / PIPE | 300,000 |

| 2020 | GAMBATGASFIELD | PPL | PAKISTAN | S31803 | SMLS PIPE | 59,000 |

| 2019 | PJSCROSNEFTOIL COMPANY | RUSSIA | TP347 | SMLS PIPE | 51,500 |

Package

Woven Bag + End Protection

Plywooden Case

English

English 中 文

中 文 Español

Español Português

Português Deutsch

Deutsch Türk

Türk Pусский

Pусский عربي

عربي 한국인

한국인 日本語

日本語