Coiled Tubing, Capillary Coil Tube, Control Line

China Coiled Tubing Manufacturer, Capillary Coil Tube, Control Line, Coiled Tubing in Oil and Gas, Coiled tubing for downhole tools, Coiled tubing for prospecting drilling.Coiled Tubing: Definition, Components, Application

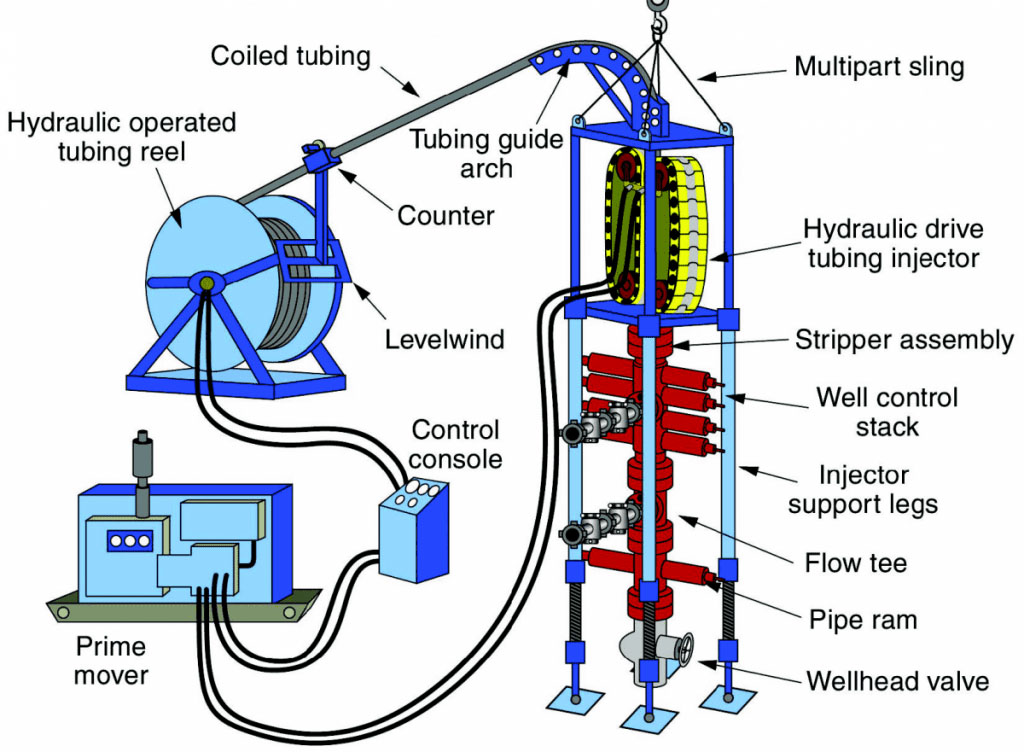

Coiled tubing (CT) refers to a continuous length of small-diameter steel tubing with no joints, which is very long and flexible, spooled on a large reel. Increasingly, the coiled tubing unit is used for many well intervention operations and certain drilling applications. At the center of any Coiled tubing (CT) surface operation is a coiled tubing unit (CTU), Including Coiled tubing with related surface equipment as well as associated drilling, completion and workover, or remediation, techniques. The most prominent feature being a reel from which a continuous length of flexible steel pipe is spooled.

Coiled tubing is available in lengths from 100 feet (30 meters) to 100,000 feet (30,000 meters). Long lengths are possible by utilizing a combination of strip splice and tube-to-tube orbital welds.

Diameters range from .250 inches (6.35 millimeters) to 1.75 inches (44.45 millimeters), with wall thicknesses up to .160 inches (4 millimeters).

2,000 to more than 30,000 ft [600 to 9,000 m].

Coiled tubing applications in the oil and gas industry

Coiled tubing is recognized as a very effective solution for deep wells. It is used for interventions in oil and gas wells and sometimes as production tubing in depleted gas wells. Additionally, it is used for cleanouts and removing filler materials. The Coiled tubing (CT) has widely applications in the oil and gas industry, which include: Drilling (CT drilling); Cementing; Wellbore cleanout; Logging and perforating; Production: CT is used as a production pipe in gas wells; Chemical circulation; Acidizing; Hydraulic fracturing; Downhole installation, i.e., electrical submersible pump installation, placing bridge plugs and packers for zonal isolation.

Coiled tubing is chosen over conventional straight tubing because conventional tubing has to be screwed together. Additionally, coiled tubing does not require a workover rig. Because coiled tubing is inserted into the well while production is ongoing, it is also a cost-effective choice and can be used on high-pressure wells.

All performed on a live well, there are a number of well intervention operations that can be achieved via coiled tubing. These include cleanout and perforating the wellbore, as well as retrieving and replacing damaged equipment.

Additionally, some advances in coiled tubing allow for real-time downhole measurements that can be used in logging operations and wellbore treatments. Enhanced Oil Recovery (EOR) processes, such as hydraulic and acid fracturing, can also be performed using coiled tubing. Furthermore, sand control and cementing operations can be performed via coiled tubing.

Capillary Coil Tube, Control Line, Chemical Injection line, Multi Core Tubing, Encapsulated Tube

Capillary coil tube specialized features can include cold working for higher yield strength, intrusion-free orbital welds and a minimized number of orbital welds. Applications include:

Capillary Coiled Stainless Steel Tubing for chemical injection;

Bare and encapsulated hydraulic control line coiled stainless steel tubing for subsea safety valves;

Velocity strings, work strings, and steel tube umbilicals;

Geothermal coiled stainless steel tubing;

Coiled tubing for shell and tube heat exchanger;

MTSCO, Since 2006. Leading Coiled Tubing Manufacturer in China

18 Year Experience, Professional RD Team, Reliable Quality, Competitive Price, Rich Stock, Standard Export Packaging, Fast Delivery, Custom Service.

MTSCO has extensive experience in producing coiled tubing from duplex, nickel alloy and stainless steel grades to industry and customer-specific requirements.

ASTM A269 TP304/304L/TP316/316L/316Ti Welded Coiled Tubing, Capillary Tube, Control Line Tubing, Hydraulic Control Line, Chemical Injection Line, Multi-Core Tubing, Tubing Encapsulated Cable, Coiled Tubing Equipment, Hydraulic Instrument Tubing, Hybrid Downhole Cable, Intelligent Coiled Tubing Cable, Seamless Coiled Tubing;

ASTM A249 TP304/304L/TP316/316L/316Ti Welded Coiled Tubing, Capillary Tube, Control Line Tubing, Hydraulic Control Line, Chemical Injection Line, Multi-Core Tubing, Tubing Encapsulated Cable, Coiled Tubing Equipment, Hydraulic Instrument Tubing, Hybrid Downhole Cable, Intelligent Coiled Tubing Cable;

ASTM A789 S31803/S32205/2205/S32750/2507 Welded Coiled Tubing, Capillary Tube, Control Line Tubing, Chemical Injection Line, Coiled Tubing Equipment

ASTM B704 Nickel Alloy Inconel 625/Incoloy 825 Capillary Tube, Chemical Injection Line

ASTM A213 TP304/304L/TP316/316L/316Ti Seamless Coiled Tubing

VIP SERVICE

VR (Virtual) Mill Introduction

Professional Remote Technical Guidanceion

Accept Third-party Inspection

Door to Door Shipment

Get QuoteSpecifications of Control Line Tubing

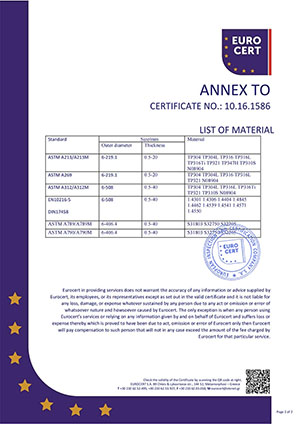

Standard |

ASTM A269 |

Materials |

Austenitic: 304/L, 316/L, 316Ti... |

Specifications |

||||||||

|

Products

Quality Control of MTSCO Coiled Tubing

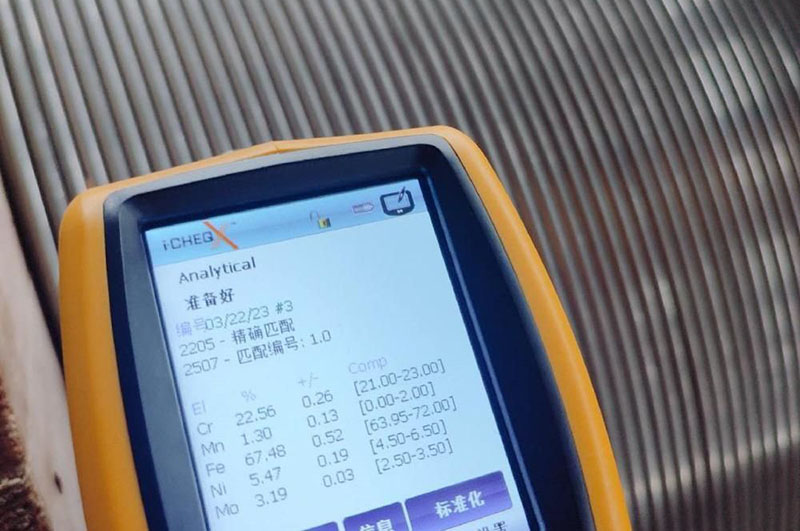

1. Quality Control of Raw Materials

Our raw materials come from large factories such as Baosteel, TSINGSHAN, WALSIN, POSCO,JISCO, ANSTEEL, ATI...Each batch of raw materials requires MTC and PMI. After the raw materials arrive, we conduct PMI and other inspections again to ensure that they meet the requirements.

2. Process Control During Production

The mainly production process includes welding, cold drawing, bright annealing and plastic wrapping.

Each process is supervised by experienced engineers and technicians. Each link is supervised by professional qc inspectors and photographed for archiving. The entire process uses process cards to ensure accuracy and traceability.

3. Quality Control Before Shipment

MTSCO has professional QC team to conduct a series of inspections and experiments on the tubes, including routine appearance, PMI, size, quantity, and other inspections. At the same time, we also conducts mechanical testing, hardness testing, airtightness,UT, ET, HT and other tests. Among them, welded coiled tubing can pass the max hydraulic pressure of 100MPA.

In addition, we also accept third-party inspection, such as SGS, TUV, and BV.

Package

As a factory complex consisting of multiple factories. MTSCO has many years of experience inpackaging and loading. The packaging are generally plastic reel, wooden reel, solid woodenreel, iron reel, iron and wooden reel, wooden boxes aand so on. Reinforcement with woodenstrips and ropes when loading cabinets.

All inspection results and loading process will be documented with photos for your traceability requirements.

English

English 中 文

中 文 Español

Español Português

Português Deutsch

Deutsch Türk

Türk Pусский

Pусский عربي

عربي 한국인

한국인 日本語

日本語