Hastelloy C276 Pipe Fittings ASTM/EN/JIS Certified, Fast Delivery

Material: Alloy 625, UNSN06625; Alloy 825, UNSN08825, 2.4858; Alloy 800, UNS N08800; Alloy C-276,UNSN10276,2.4819; Alloy B-3, UNS N10675; Alloy C-4, UNS N06455; Alloy C22, UNS N06022; UNS N02201, UNS N02200;

Get Quote

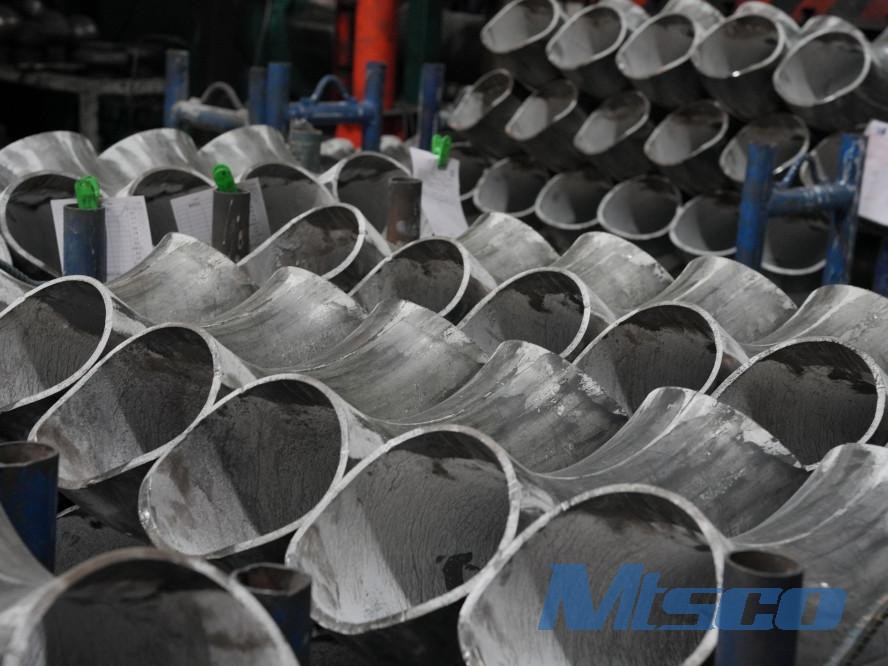

Hastelloy C276 Fittings, Alloy C276 Butt weld Pipe/Tube Elbows

Nickel alloy C276 is a nickel - molybdenum - chromium superalloy known for its excellent corrosion resistance, especially in aggressive environments containing chloride ions. These fittings and elbows are precision - engineered, suitable for various industrial applications such as chemical processing, petrochemical, and pollution control. They offer reliable performance and long - term durability, ensuring a seamless connection in piping systems. Whether used in new installations or replacements, they are a great choice for ensuring the integrity and efficiency of your pipelines.

Commodity | Concentric Reducer & Eccentric Reducer , Reducing Tee & Equal Tee, Elbow 45° , 90° , 180° , Cross , Cap , Stub End, etc |

Process Method | Cold Forming |

Grade | TP304/L, TP316/L/Ti, TP321, S31254, S32205, S32750, Alloy 600/601/625/825/C276/C22... |

Standards | ASTM A403 , A815, B366, EN 10253-4... |

Size Range | OD: ≤2000mm; ≤DN2000; ≤80'' |

Tolerances | according to the specification or customer’s request and drawings |

Applications | oil & gas industry , chemical industry , electric power , boiler and heat exchanger , machinery , metallurgy , sanitary construction etc . |

Surface treatment for Alloy C276 Elbows

Buttweld fittings, BW fittings, tees, elbows and reducers are given a standardized sandblasted surface treatment, which enhances the corrosion resistance of the fittings and ensures a consistent finish. Sandblasting removes contaminants and optimizes adhesion of subsequent coatings or welds. Surface finish inspections include PMI inspections, dimensional and cosmetic inspections to meet ASTM/EN specifications. Laboratory testing verifies mechanical properties and chemical composition, especially for austenitic steels, duplex steels, and nickel alloys.

Why Choose MTSCO Pipe Fitting?

Strategic manufacturing partnership

Production is managed by Hongdi. We have obtained ISO/PED/CRN/TS/M650 certification to ensure that materials meet standards and are traceable. Advanced CNC machining and hydraulic press systems can accurately manufacture stainless steel elbows.

Comprehensive quality assurance

A multi-stage inspection process, including PMI verification of raw materials, photo records of the production process and archiving, as well as 100% pre-delivery testing. Third-party inspections such as SGS/TUV/BV are acceptable.

Transportation plan guarantee

A customized packaging solution with reinforced wooden cases and real-time loading documents is adopted to ensure the safe delivery of goods. With a monthly production capacity of 200 tons, full-container orders can be efficiently delivered within 20 - 30 days.

Technical collaboration

Remote factory visit and audit through virtual reality (VR:https://www.720yun.com/t/12vk69iypfh?scene_id=100992757) simplify the project approval process. Customized services cover non-standard sizes, prefabricated components, and surface treatment of specific materials.

Application Areas of Alloy C276 Pipe Fitting:

Nickel alloy C276 pipe fittings are widely used in chemical processing plants, in reactors, heat exchangers, and transfer pipelines for handling chlorides, sulfuric acid, and other corrosive media.

The oil and gas industry uses them in offshore platforms and refinery equipment exposed to sulfur-containing gas environments. Their excellent resistance to pitting corrosion and stress corrosion cracking makes them suitable for flue gas desulfurization systems, nuclear fuel reprocessing plants, and offshore engineering applications.

They are crucial in pharmaceutical manufacturing for aseptic processing equipment and waste treatment facilities handling acidic by-products.

Power plants also use them extensively in scrubber systems and boiler feed water loops.

These pipe fittings comply with the ASTM B366/B462 standards and meet the strict requirements of petrochemical pipelines, industrial pollution control systems, and special chemical transportation infrastructure.

VIP SERVICE

VR (Virtual) Mill Introduction

Professional Remote Technical Guidanceion

Accept Third-party Inspection

Door to Door Shipment

Get QuoteRelated Products: Pipe Fittings: Butt Welded Pipe Fittings

WP321 / 1.4541 Flanges Pipe Fittings For Connection , ASTM A403 Stainless Steel Tee

MTSCO is a leading manufacturer who is specialized in stainless steel seamless pipes , bright annealed tubes , seamless coiled tubing etc . In order to facilitate customers , we have pipe fittings and flanges too . MTSCO has the most advanced producing and testing equipment . We can totally satisfy ......

ASTM A815 / ASME SA815 F51 / F53 Duplex Steel Eccentric Reducer Pipe Fitting

MTSCO is a leading manufacturer who is specialized in stainless steel seamless pipes , bright annealed tubes , seamless coiled tubing etc . In order to facilitate customers , we have pipe fittings and flanges too . MTSCO has the most advanced producing and testing equipment . We can totally satisfy ......

ASTM A182 S31803 / S32750 Duplex Steel Comcentric & Eccentric Reducer

MTSCO is a leading manufacturer who is specialized in stainless steel seamless pipes , bright annealed tubes , seamless coiled tubing etc . In order to facilitate customers , we have pipe fittings and flanges too . MTSCO has the most advanced producing and testing equipment . We can totally satisfy ......

English

English 中 文

中 文 Español

Español Português

Português Deutsch

Deutsch Türk

Türk Pусский

Pусский عربي

عربي 한국인

한국인 日本語

日本語