Alloy K-500, UNS N05500, Nickel Alloy Steel Pipe/Tube, Flanges, Fittings

Alloy K-500(UNS NO5500) | |||||||||

Summary | A precipitation-hardenable nickel-copper alloy that combines the corrosion resistance of alloy 400 with greater strength and hardness. It also has low permeability and is nonmagnetic to temperatures as lowas -101°. Used for pump shafts, oil-well tools and instruments, doctor blads and scrapers, springs, value rim, fasteners, and marine propeller shafts. | ||||||||

Standard Product Forms | Pipe, tube, sheet, strip, plate, round bar, flat bar, forging stock, hexagon and wire. | ||||||||

Chemical Composition Wt,% |

| Min | Max. |

| Min. | Max. |

| Min. | Max. |

Ni | 63.0 |

| Cu | 27.0 | 33.0 | C |

| 0.18 | |

Cr |

|

| Co |

|

| Si |

| 0.5 | |

Fe |

| 2.0 | Al | 2.3 | 3.15 | P |

|

| |

Mo |

|

| Ti | 0.35 | 0.85 | S |

| 0.01 | |

W |

|

| Mn |

| 1.5 | N |

|

| |

Physical Constants | Density,g/ | ||||||||

Melting Range,℃ 1315-1350 | |||||||||

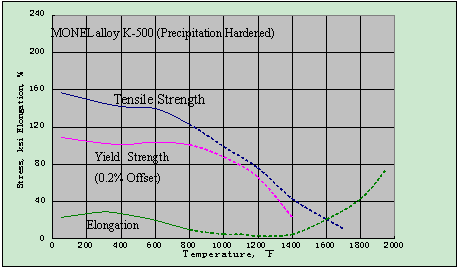

Typical Mechanical Properties | (Precipitation Hardened) Tensile Strength, ksi 160 Mpa 1100 Yield Strength (0.2% Offset),ksi 115 Mpa 790 Elongation, % 20

|

Microstructure

alloy K-500 which is produced by adding aluminum and titanium to the basic MONEL nickel-copper composition also has a face-centered cubic structure. In the age-hardened condition a submicroscopic gamma prime Ni3Al phase is formed throughout the matrix.

Characters

Alloy k500 has excellent corrosion resistance in an extensive range of natural and chemical environments, excellent resistance to chloride-ion stress-corrosion cracking and very high strength and hardness.After age-hardening, Alloy K500 has approximately 2 to 3times higher mechanical properties than the nickel-copper alloy (Monel 400), high tensile properties up to about 650℃,good corrosion fatigue resistance and ow permeability with non-magnetic down to -135℃.

Corrosion Resistance

In general, the corrosion resistance of Alloy K500 is similar to that of Alloy 400. Excellent resistance is shown to a wide range of media from pure water to mineral acids, salts and alkalis. Alloy K500 is virtually immune to chloride-ionstress-corrosion cracking. In the aged condition, the alloy may be susceptible to stress-corrosion cracking in most, aerated hydrofluoric acid vapour at stresses near the yield strength. In high-velocity seawater and in marine atmospheres, good corrosion resistance is shown but, in slow-moving or stagnant seawater, pitting may occur. Nicorros Al also shows good resistance in sour-gas environment.

Applications

Alloy K500 finds wide application in the marine, chemical, petrochemical and shipbuilding industries.Typical applications include;

1. Valve seals, pump sleeves and wear rings in marine environments-high strength and resistance to seawater.

2. Doctor blads and scrapers;

3. Fasteners, e.g. Bolts, used in marine atmospheres and tidal waters - resistance to chloride-containing environments;

4. Towing cable armouring - high strength, non-magnetic properties and resistance to seawater;

5. Oil well drilling equipment such as non-magnetic drill collars, valves and instrumentation sleeves - resistance to chloride-containing nedia and sour-gas environments'

6. Springs - resistance to a variety of corrosive media;

7. Aviation instrument components - non-magnetic.

English

English 中 文

中 文 Español

Español Português

Português Deutsch

Deutsch Türk

Türk Pусский

Pусский عربي

عربي 한국인

한국인 日本語

日本語