Alloy 600, UNSN06600, Nickel Alloy Steel Pipe/Tube, Flanges, Fittings

Alloy 600 (UNS N06600) | |||||||||

Summary | A nickel-chromium alloy with good oxidation resistance at high temperatures and resistance to chloride-ion stress-corrosion cracking, corrosion by high-purity water, and caustic corrosion. Used for furnace components, in chemical and food processing, in nuclear engineering, and for sparking electrodes. | ||||||||

Standard Product Forms | Pipe, tube, sheet, strip, plate, round bar, flat bar, forging stock, hexagon and wire. | ||||||||

Chemical Composition Wt,% |

| Min | Max. |

| Min. | Max. |

| Min. | Max. |

Ni | 72.0 |

| Cu |

| 0.5 | C |

| 0.15 | |

Cr | 14.0 | 17.0 | Co |

|

| Si |

| 0.5 | |

Fe | 6.0 | 10.0 | Al |

|

| P |

|

| |

Mo |

|

| Ti |

|

| S |

|

| |

W |

|

| Mn |

| 1.0 | N |

|

| |

Physical Constants | Density,g/ | ||||||||

Melting Range,℃ 1354-1413 | |||||||||

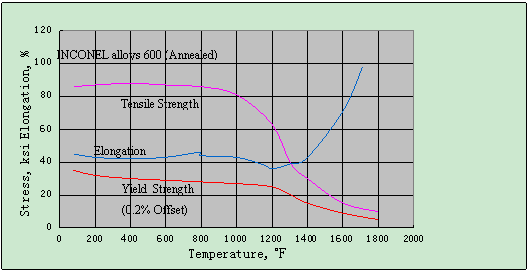

Typical Mechanical Properties | (Annealed) Tensile Strength, ksi 95 Mpa 655 Yield Strength (0.2% Offset),ksi 45 Mpa 310 Elongation, % 40 | ||||||||

|

Microstructure

Alloy 600 has a face-centered cubic structure and is a stable, austenitic solid-solution alloy.

Characters

A good corrosion resistance to the media of reducing, oxidation and nitridation;

Virtual immunity to chloride-ion stress-corrosion cracking even at elevated temperatures;

Very good resistance ti high-temperature corrosion in drychlorine and hydrogen chloride.

Corrosion Resistance

The composition of Alloy 600 enables it to resist a variety of corrosives. The chromium content of the alloy makes it superior to commercially pure nickel under oxidizing condition, and its high nickel content enables it to retain considerable resistance under reducing condition. The nickel content also provides excellent resistance to alkaline solutions.

The alloy has fair resistance to strongly oxidizing acid solution. However, the oxidizing effect of dissolved air alone is not sufficient to insure complete passivity and freedom from attack by air-saturated mineral acids and certain concentrated organic acids.

Applications

1. Pressurised-water-reactor steam-generator tube;

2. Heat exchangers for sodium hydroxide;

3. Component used in the manufacture of photographic materials and film processing;

4. Oxychlorinator internals in vinyl chloride production;

5. Strip for flight recorders.

English

English 中 文

中 文 Español

Español Português

Português Deutsch

Deutsch Türk

Türk Pусский

Pусский عربي

عربي 한국인

한국인 日本語

日本語