From Strength to Corrosion Resistance: Key Elements in Pressure Vessel Material Selection

Core material selection criteria:

Mechanical properties: the material needs to meet the design strength requirements, can withstand the working pressure and structural stresses

Corrosion resistance: need to adapt to the characteristics of the medium and environmental conditions, to ensure that the service life

Economy: comprehensive assessment of material costs, processing costs and maintenance expenditures

Craftsmanship: good processing and molding capabilities (welding / bending, etc.), to facilitate the installation of internal components

Availability: Material specifications should be in line with industry standards to ensure supply stability.

Comparison of common material properties:

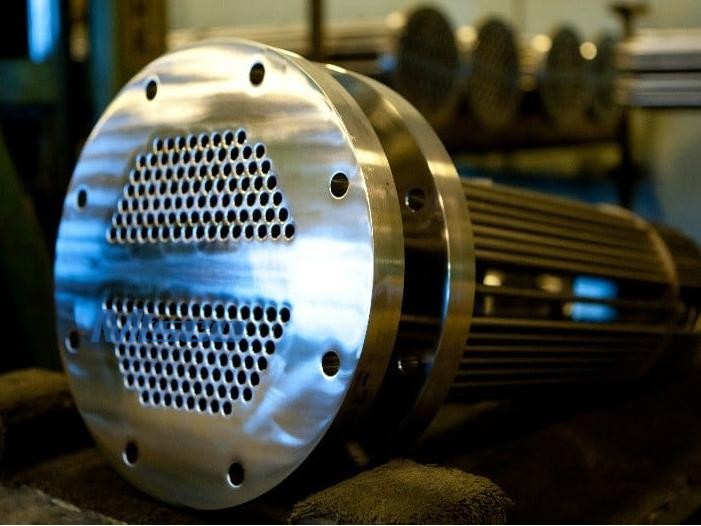

Stainless Steel (MTSCO core product)

▫ Material Coverage: 304/304L, 316/316L, 31803 and other austenitic/duplex steels

▫ Advantage: Chromium forms a passivation film, excellent chemical corrosion resistance

▫ Characteristics: good ductility, easy processing and molding, low maintenance costs

▫ Applications: food/chemical containers

Nickel Alloys (MTSCO area of specialization)

▫ Models available: Monel 400, Alloy 625, Alloy 825, etc.

▫Strengths: Outstanding performance in extreme conditions (high temperature/corrosion)

▫ Characteristics: high crack resistance, service life of more than 20 years

▫ Application: petrochemical/nuclear core equipment

Carbon Steel

▫ Strengths: low cost, high strength (thinnest wall thickness), impact resistance

▫ Limitations: poor corrosion resistance, difficult to mold

▫ Applications: conventional pressure vessels

Lightweight Metals

Aluminum: high strength and light weight, suitable for laboratory vessels (non-high pressure)

Titanium: biocompatible, excellent thermal conductivity, suitable for medical/heat exchange equipment

MTSCO Technology Enablement

19 years of experience in heat exchanger tube/fitting/flange manufacturing, providing full material solutions:

√ Austenitic stainless steel series √ Duplex steel special material √ Nickel alloy customization

From raw material certification to process guidance, the whole process of technical support to ensure the reliability of the equipment.

Immediately open the efficient selection of materials:

Call MTSCO, senior engineers for your customized cost reduction and efficiency programs

Choose MTSCO, let the material performance and project budget accurately match!

English

English 中 文

中 文 Español

Español Português

Português Deutsch

Deutsch Türk

Türk Pусский

Pусский عربي

عربي 한국인

한국인 日本語

日本語