What is the purpose of coiled tubing?

——High-Performance Tubing for Oil Extraction, Heat Transfer, and Industrial

Discover the purpose and benefits of coiled tubing in oil extraction, heat transfer, and industrial fluid transport. Learn about materials, standards, and applications.

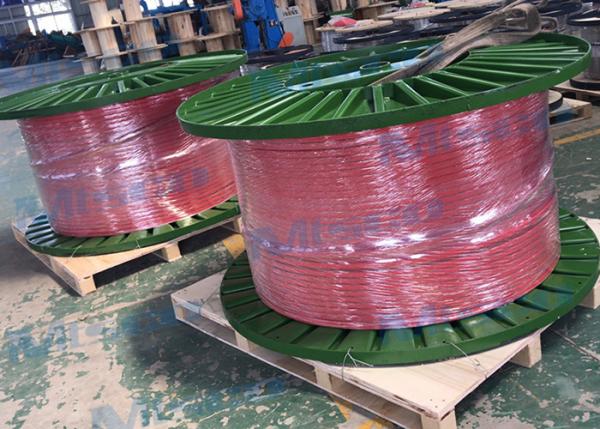

Coiled Tubing (CT) is a high-performance tubing widely used in oil extraction, heat transfer equipment and industrial fluid transportation. Its continuous coiled structure design reduces the number of connection points, improves the overall strength and sealing, and is suitable for high pressure, high temperature and corrosive environments.MTSCO, as a professional control line manufacturer, provides high-quality tubing including Welded Coiled Tubing and Encapsulated Control Line, in materials ranging from 304, 316, 2205, 2507, 304, 316, 2205 and 2507. The materials include 304, 316, 2205, 2507 and Alloy 625/825, which can meet the stringent requirements of different industrial applications.

Stainless Steel 304/316: Suitable for conventional oil well water injection, low pressure heat transfer systems, and cost-effective in pH-neutral environments;

Duplex steel 2205/2507: its duplex microstructure (ferrite + austenite) gives it 2-3 times the resistance to pitting corrosion of conventional stainless steels, which makes it particularly suitable for oil and gas wells containing hydrogen sulphide or seawater cooling systems;

Nickel-based alloys 625/825: their resistance to high-temperature sour media (temperatures up to 600°C) makes them ideal for geothermal mining and refinery cracking units. For example, MTSCO's Alloy 625 coiled tubing, customized for a deepwater drilling rig in the Gulf of Mexico, operated continuously for more than 20,000 hours without stress corrosion cracking at 150°C downhole in an environment containing 15% CO₂.

Coiled tubing is essentially a continuous seamless metal piping system, whose core function is to realize the closed transmission of media, energy exchange and process control. Compared with the traditional segmented pipeline, its technical advantages are reflected in:

Continuous operation capability: single length up to 6000 meters, eliminating the need for on-site welding.

Dynamic response advantage: Reel storage supports rapid deployment and recovery.

Adaptability to Complex Conditions: Optimized materials and structures to handle high pressure (70MPa), high temperature (650°C) and corrosive media.

MTSCO's welded/encapsulated coiled tubing are manufactured in strict compliance with standards, providing full size coverage from Φ3.18mm miniature instrumentation tubes to Φ38.1mm process lines to meet the needs of diverse industrial scenarios.

MTSCO--Your Reliable Coil Supplier

As a leading global manufacturer of control lines, MTSCO is committed to providing high-quality coiled tubing products for the oil extraction and heat exchange equipment industries. Our strict adherence to international standards ensures that every coil maintains its performance under extreme conditions. Whether it's for high-pressure oil well operations, deep-sea oil and gas control, or industrial heat exchanger systems, we offer the best selection of materials and technical support. Contact us for more product information and customized solutions, we look forward to working with you!

Related Products

Nickel Capillary Tube Alloy 825/625 Downhle Welded Coiled Tube For Oilfield Services

An increasing number of projects in the oil service industry require the use of continuous lengths of stainless steel control lines. They are used in a variety of applications, including chemical injection, hydraulic control, instrumentation umbilicals and flowline control. MTSCO offers products ......

English

English 中 文

中 文 Español

Español Português

Português Deutsch

Deutsch Türk

Türk Pусский

Pусский عربي

عربي 한국인

한국인 日本語

日本語