Welded Pipe

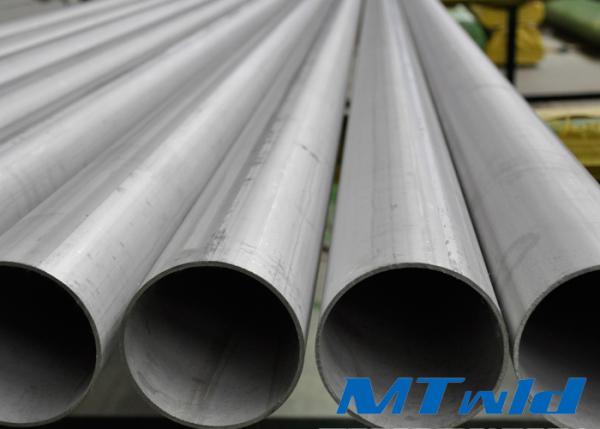

35 Years Welded Pipe Manufacturing Experience,Meet Your Various Needs.Welded pipes are manufactured through welding processes, with joints along their length. Generally, there are welding methods such as ERW, EFW, PAW, etc. According to the welding technology used, the joint can be longitudinal or spiral. These pipelines have extensive applications in fields such as construction, infrastructure, and manufacturing. Their versatility allows customization based on specific project requirements, making them a popular choice for transporting liquids, gases, and solids. Welded pipelines are a reliable solution with relatively lower production costs, shorter production cycles, and flexible production scales compared to seamless pipes, making significant contributions to the growth and development of modern industry.

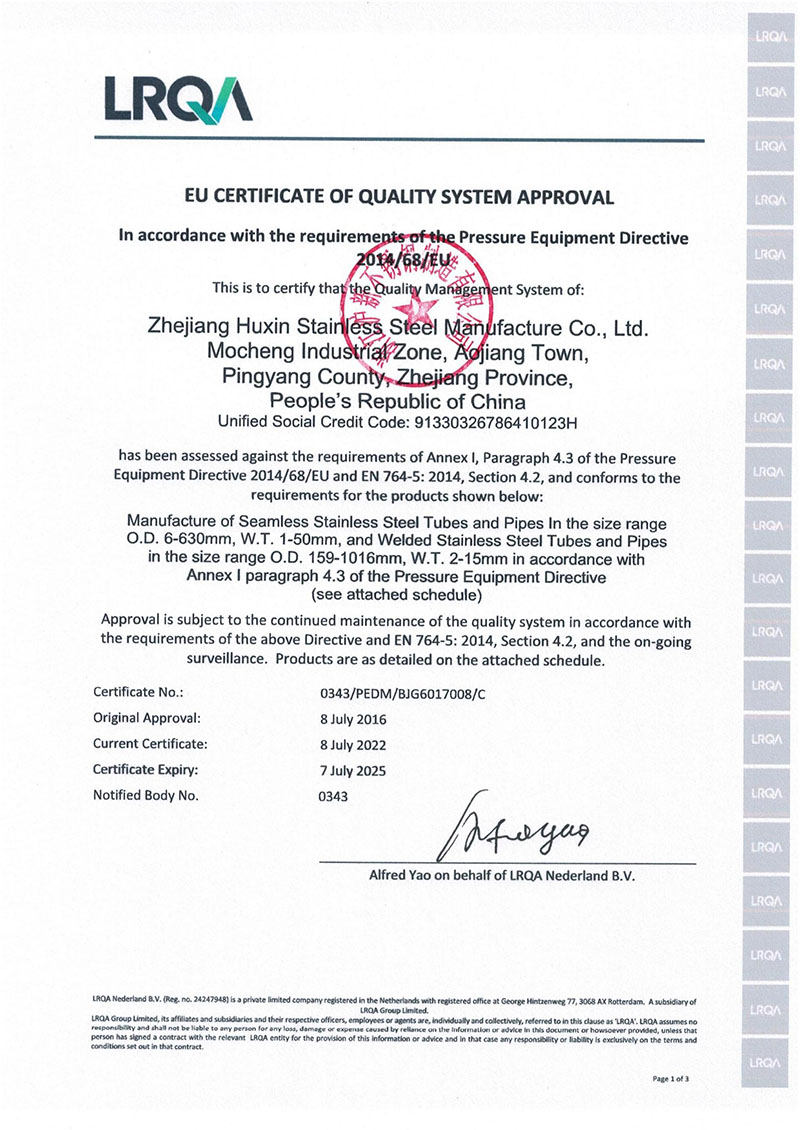

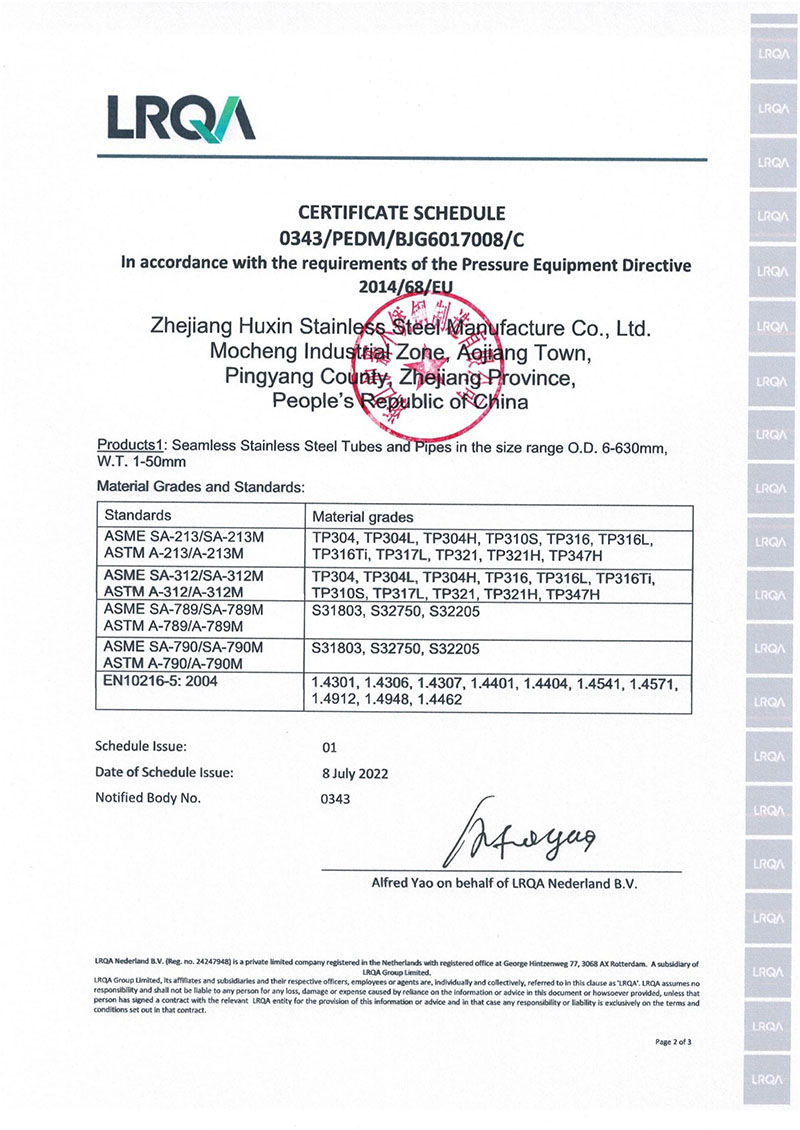

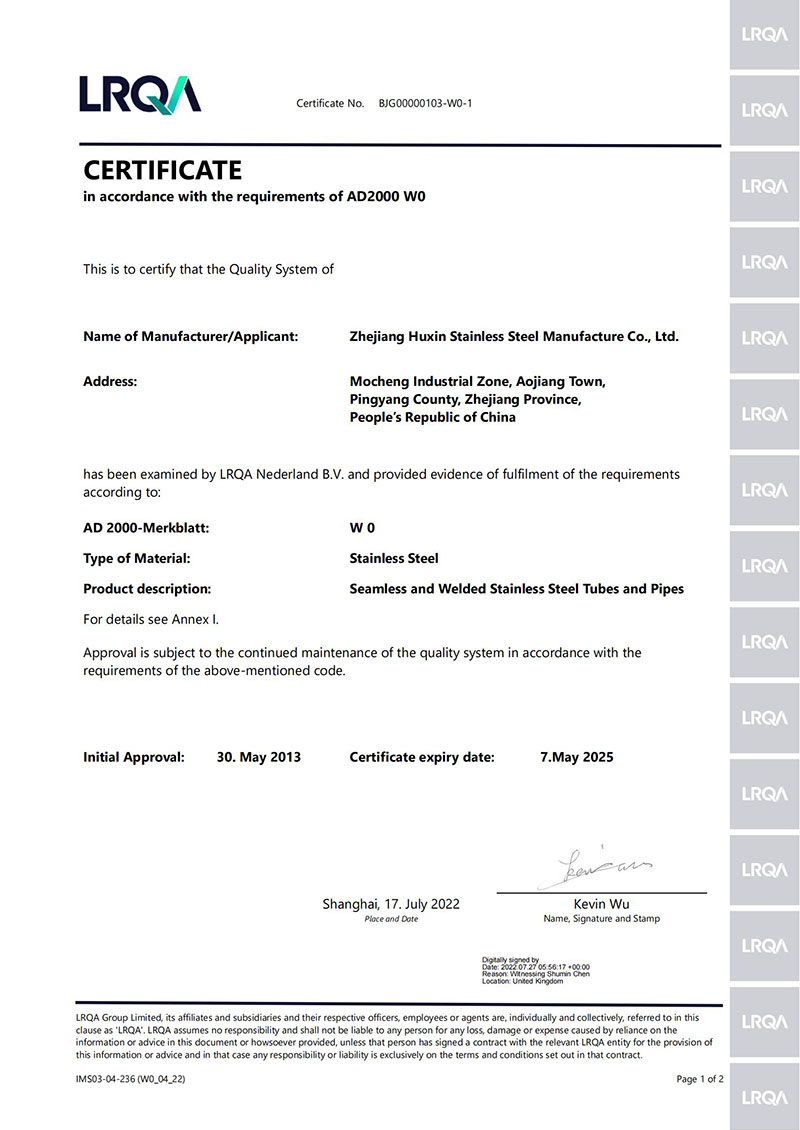

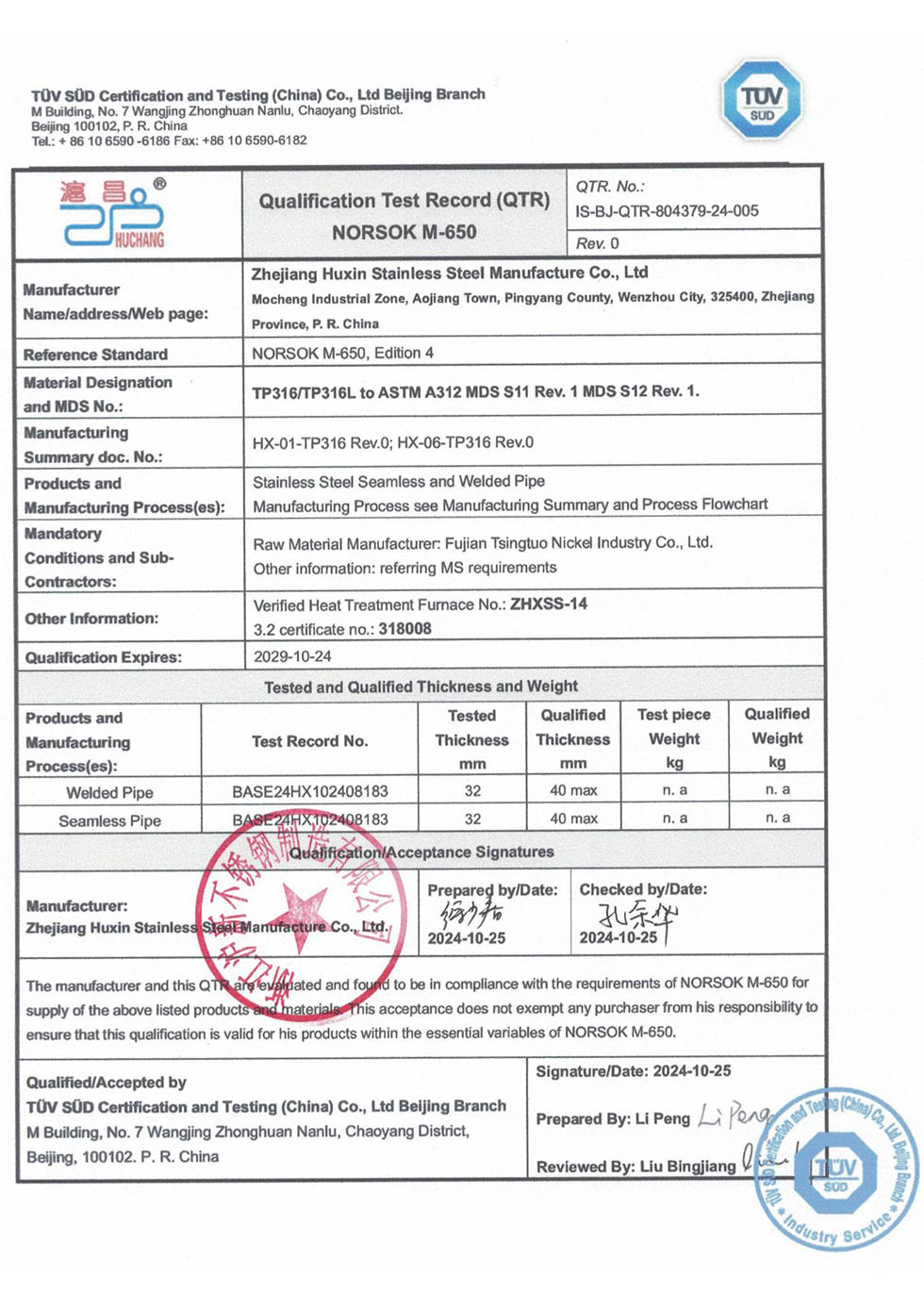

MTSCO welded pipes have a highly guaranteed supply chain. MTSCO has invested in a factory - HUXIN PIPE, which has 35 years pipe manufacturing experience. MTSCO has reached a high strategic partnership with Huxin, becoming the only international sales center of Huxin.

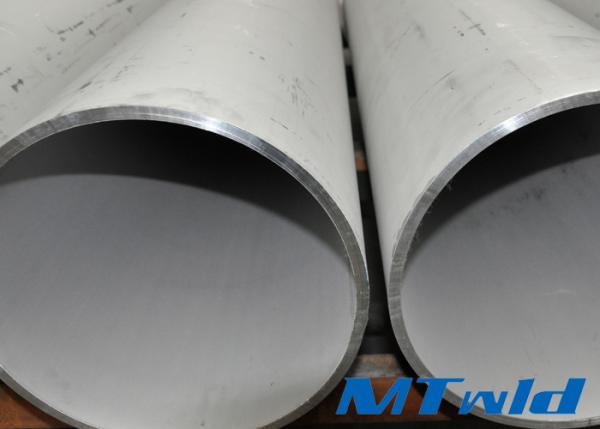

In the realm of traditional technology, Huxin has revamped its welded pipes, effectively resolving the issue of non-circular welds in larger-sized welded pipes. A significant advancement comes through the box annealing furnace (12m), ensuring comprehensive pipe annealing and accommodating special materials with a remarkable maximum temperature capacity of 1200 ℃.

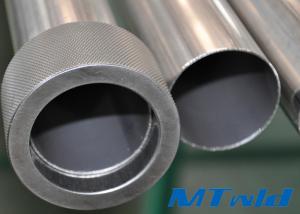

Within the factory's premises, an array of production, inspection, and laboratory equipment graces the scene, including CNC bending machines, automatic welding machines, and integrated eddy current ultrasonic systems.

VIP SERVICE

VR (Virtual) Mill Introductionn

Professional Remote Technical Guidanceion

Accept Third-party Inspection

Door to Door Shipment

Get QuoteSpecifications of Welded Pipe

Standard |

ASTM-A312 |

Materials |

Austenitic: 300 Series... |

Specifications |

||||||||

|

Products

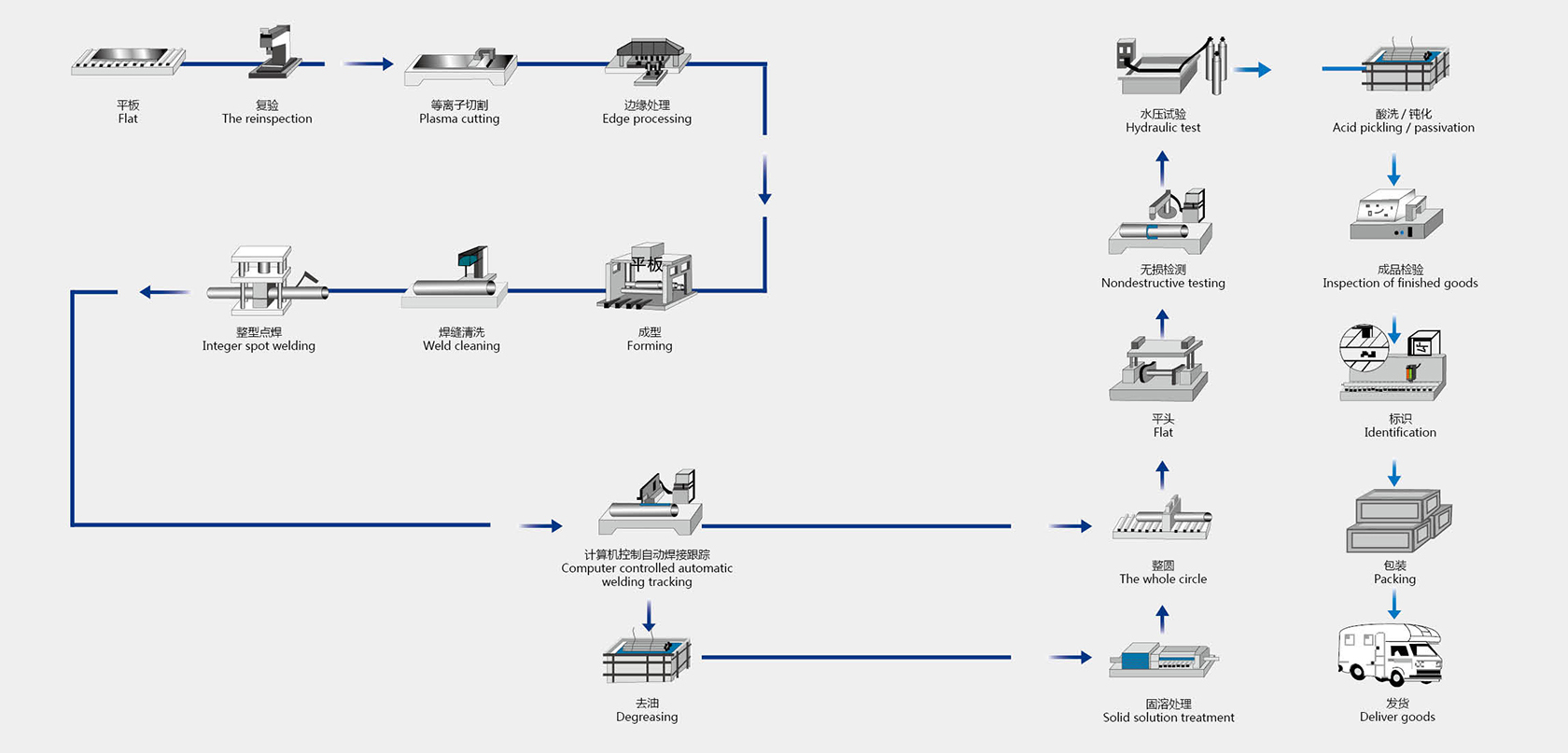

Welded Pipe Production Process

Quality Control of MTSCO Welded Pipe

1. Quality Control of Raw Materials

Our raw materials come from large factories such as Baosteel, Tisco,TSINGSHAN, Eastern SpecialSteel... Each batch of raw materials requires MTC and PMI. After the raw materials arrive, weconduct PMI and other inspections again to ensure that they meet the requirements.

2. Process Control During Production

MTSCO welded pipe is mainly formed by rolled plate (RBE) and bending, and the welding adoptsPAW+GTAW. The whole process is automatic welding, which makes the welding efficiencyincrease and the weld seam more full and stable. Huxin's welded pipes have been upgraded intraditional technology, solving the problem of non circular welds in large size welded pipes, anduse the 12-meter annealing furnace to make the annealing of the pipe more complete.

Each process is supervised by experienced engineers and technicians. Each link is supervised byprofessional qc inspectors and photographed for archiving. The entire process uses processcards to ensure accuracy and traceability..

3. Quality Control Before Shipment

MTSCO has professional QC team to conduct a series of inspections and experiments on thepipes, including routine appearance, PMI, size, quantity, and other inspections. At the sametime, we also conducts mechanical testing, hardness testing, X-ray test, UT, ET, HT and othertests. Hydrotesting can test pipes with a maximum OD of 630mm, and we also perform 100% Xray testing of welds.

In addition, we also accept third-party inspection, such as SGS, TUV, and BV.

Project Cases

| Year | Project | End User/ EPC | Site | Material | Products | QTY(KGS) |

| 2018 | OTI HEAT EXCHANGERS | OLYMPUS TECHNOLOGIES,INC. | AMERICA | S32760 | WELDED PIPE | 120,000 |

| 2019 | BOKOR PHASE 3 REDEVELOPMENT PROJECT | PETRONAS | MALAYSIA | 304L/316L | SMLS/WELDED PIPE | 100,000 |

| 2023 | PROJECT SAHARAROSE | MNHE | MALAYSIA | 304L316L | SMLS/WELDED PIPE FITTINGS |

40,000 |

Package

Woven Bag

Normal Loading

English

English 中 文

中 文 Español

Español Português

Português Deutsch

Deutsch Türk

Türk Pусский

Pусский عربي

عربي 한국인

한국인 日本語

日本語