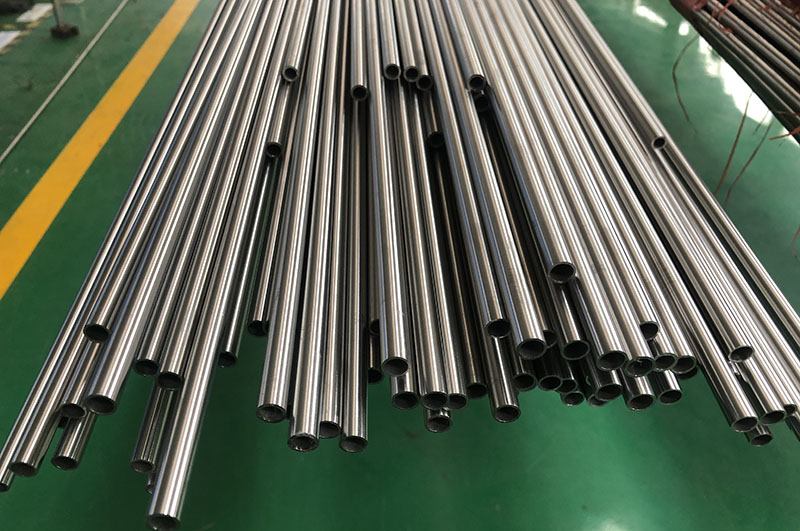

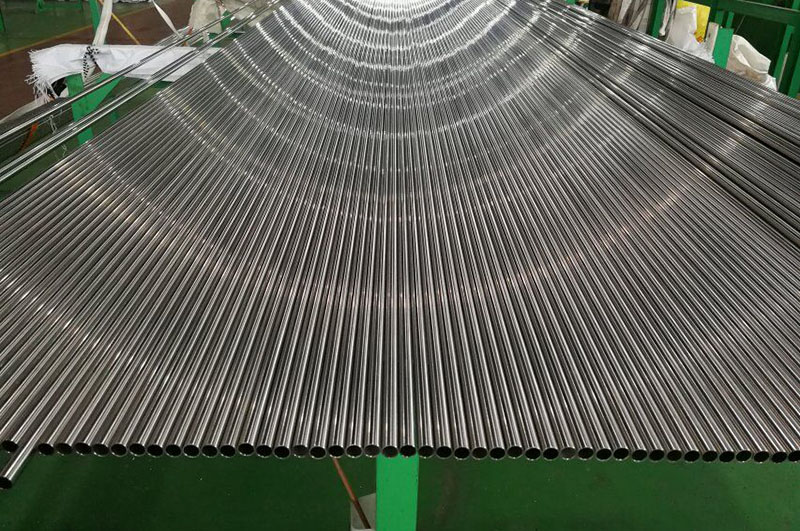

Seamless Tube

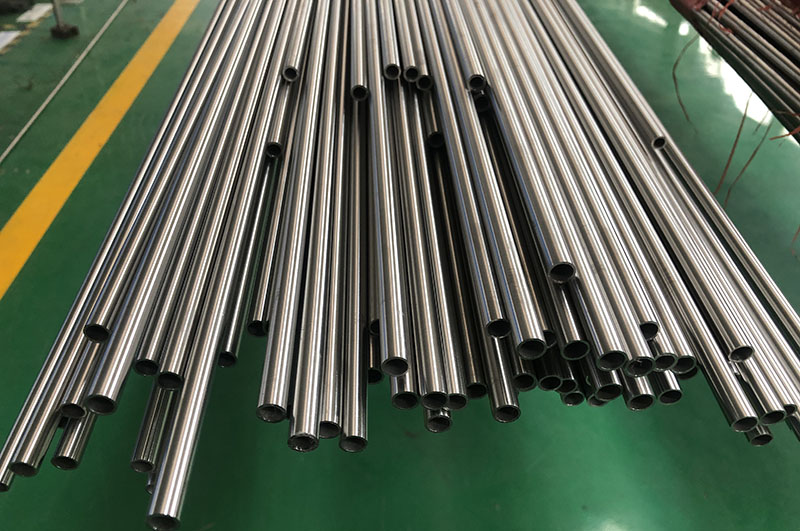

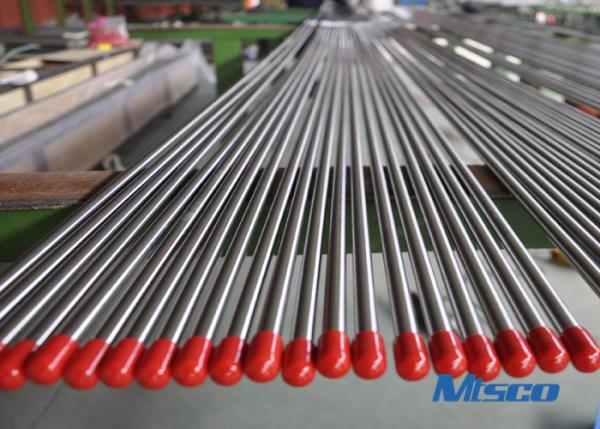

35 Years Seamless Tube Manufacturing Experience,Meet Your Various Needs.Seamless tube is a microcosm of precision engineering, which is a type of precision tube characterized by small diameter and thin wall thickness. It is made through high-precision cold drawing or hot rolling processes, ensuring uniformity in thickness and consistent mechanical properties throughout the entire length. This uniformity endows them with extraordinary strength, making them suitable for critical applications in industries such as aerospace, automotive, and energy. Its smooth surface treatment not only enhances its visual appeal, but also reduces friction, helping to improve fluid flow efficiency. These pipelines are seamlessly manufactured and can be used as pipelines for liquids, gases, and solids. Their unparalleled durability and reliability highlight their role as fundamental components in various industrial sectors.

MTSCO can produce seamless tubes of varying lengths, including extended ones like 18 meters and 25 meters.

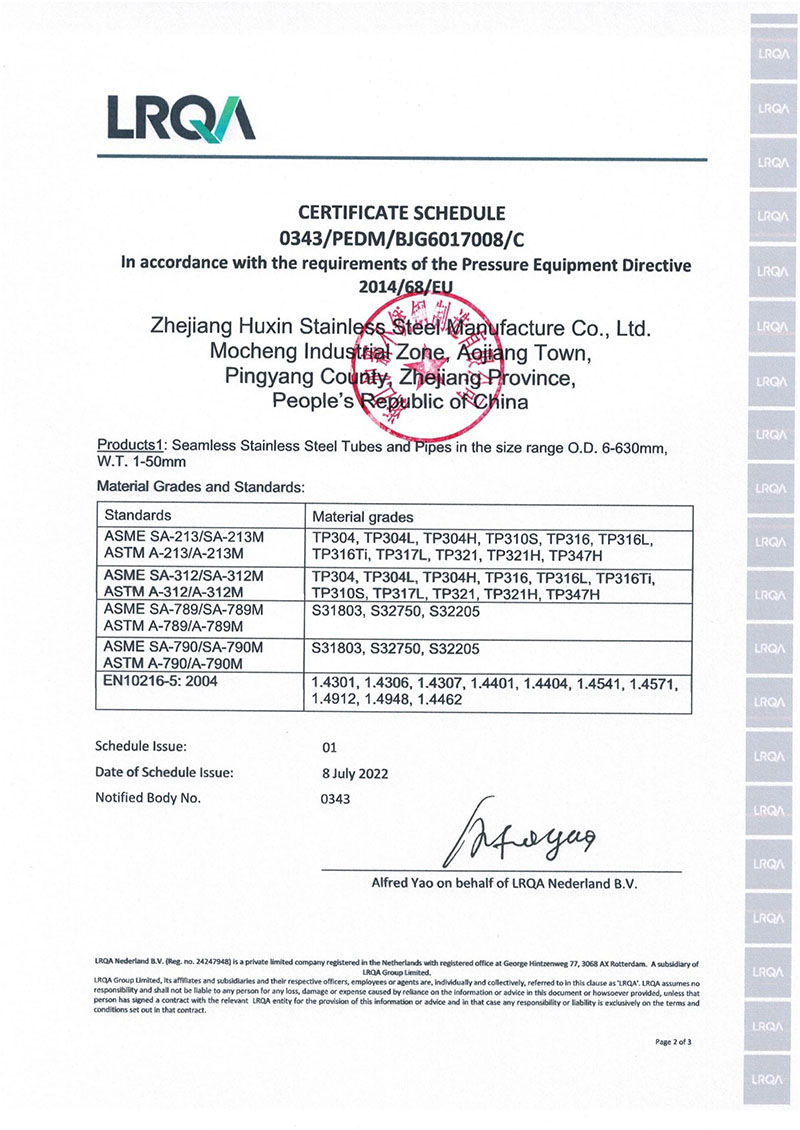

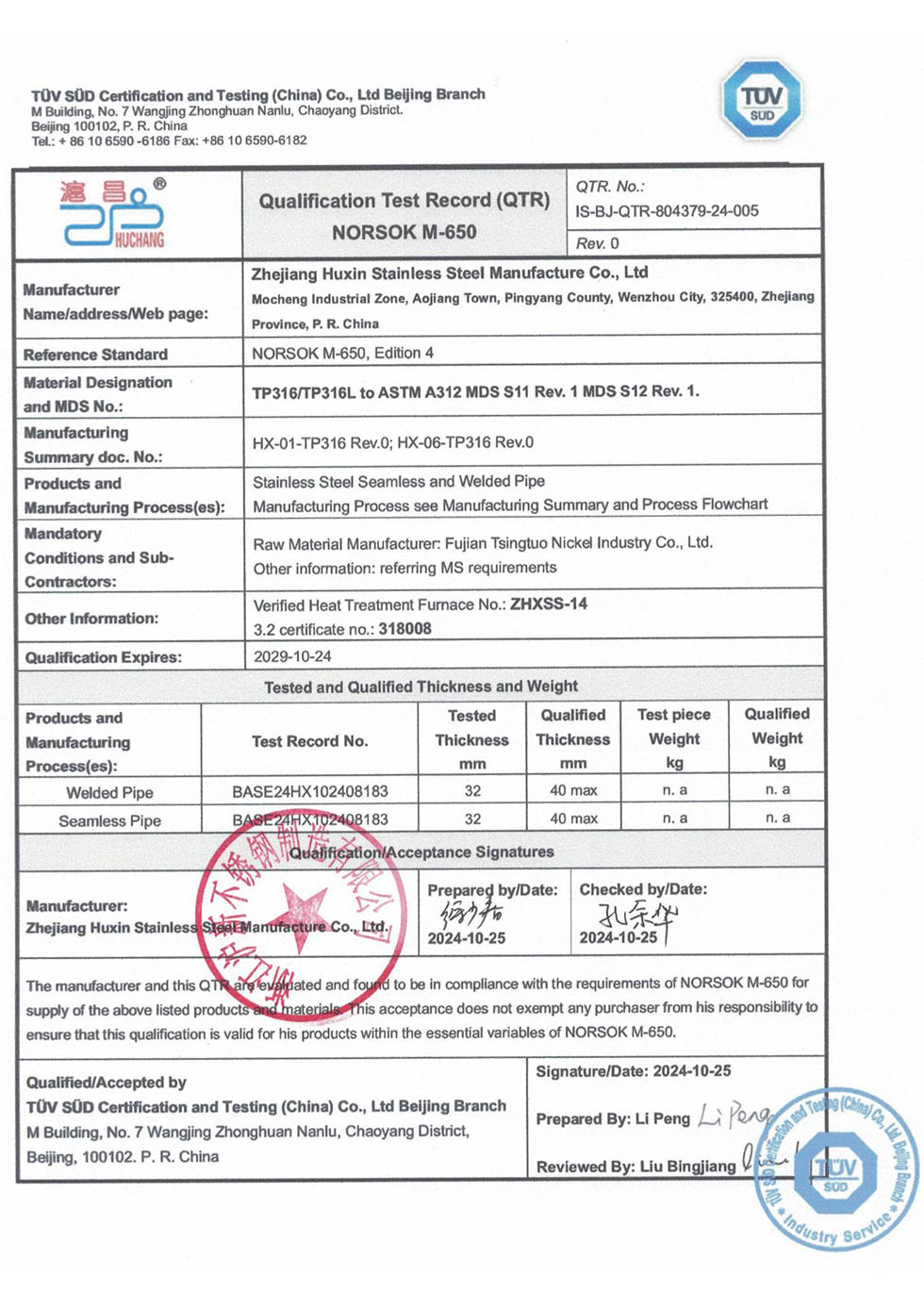

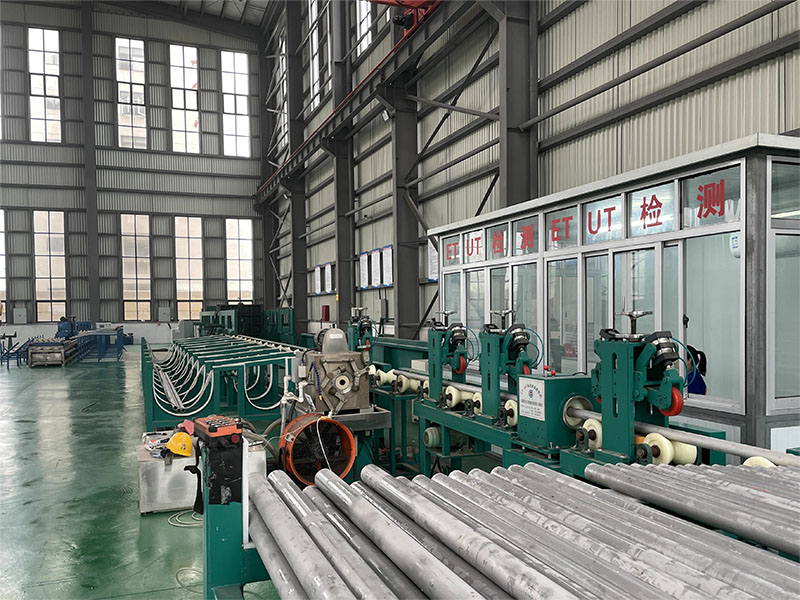

MTSCO factory is fully equipped with production, inspection, and laboratory equipment like cold rolling machines, annealing furnaces, pickling pools, and integrated eddy current ultrasonic systems.

These pipes from MTSCO have found extensive application in industrial constructions across diverse global regions. Our customers' satisfaction resonates through their feedback and appreciation, fostering numerous enduring and deep-seated partnerships.

VIP SERVICE

VR (Virtual) Mill Introduction

Professional Remote Technical Guidanceion

Accept Third-party Inspection

Door to Door Shipment

Get QuoteSpecifications of Seamless Tube

Standard |

ASTM A269 |

Materials |

Austenitic: 300 Series... |

Specifications |

||||||||

|

Products

Different Types of Seamless Tube MTSCO Mainly Supply

Annealed Pickled (Heat Exchanger) Tube

Dedicated to transferring heat between two fluids, usually a hot and a cold one, without commingling, heat exchanger tubes hold a specialized status. Engineered for superior thermal conductivity and corrosion resistance, these tubes guarantee both effective heat transfer and prolonged resilience. With diverse applications across power generation, chemical processing, oil refineries, and HVAC systems, heat exchanger tubes emerge as pivotal players. Their significance in upholding optimum temperatures and energy efficiency deems them indispensable components, seamlessly enabling efficient heat exchange to meet tailored production needs in various industrial sectors.

Annealed Pickled + Polished Tube

The Annealed Pickled Polished Tube, first undergoes an annealing process for enhanced ductility. Following this, meticulous pickling eliminates surface impurities, and a final polish yields a sleek and pristine surface. This impeccable refinement renders the tube ideally suited for high-purity environments and critical industries, where its performance seamlessly aligns with stringent quality demands.

Bright Annealed + Polished Tube

Undergoing a meticulous bright annealing process, the Bright Annealed Polished Tube emerges as a top-tier tube, characterized by its impeccably smooth and glossy surface. This attribute renders it apt for an array of precision applications within sectors like electronics, medical technology, and instrumentation, where the demand for excellence is paramount.

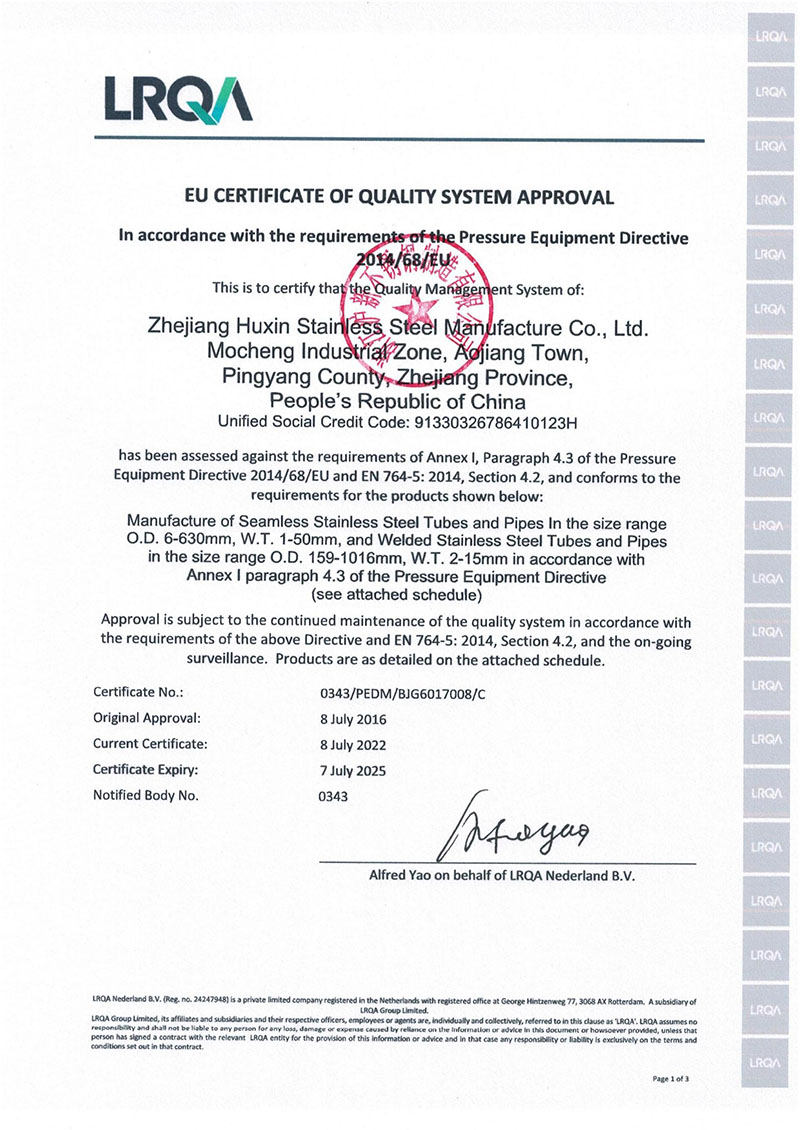

Quality Control of MTSCO Seamless Tube

1. Quality Control of Raw Materials

Our raw materials come from large factories such as Baosteel and TSINGSHAN. Each batch ofraw materials requires MTC and PMI. After the raw materials arrive, we conduct PMI and otherinspections again to ensure that they meet the requirements.

2. Process Control During Production

Each process is equipped with advanced production equipment, and is supervised byexperienced engineers and technicians. Each link is supervised by professional qc inspectorsand photographed for archiving. The entire process uses process cards to ensure accuracy andtraceability.

3. Quality Control Before Shipment

MTSCO has professional QC team to conduct a series of inspections and experiments on thetubes, including routine appearance, PMI, size, quantity, and other inspections. At the sametime, we also conducts mechanical testing, hardness testing, UT, ET, HT and other tests. Inaddition, we also accept third-party inspection, such as SGS, TUV, and BV.

Before shipping, we use appropriate and safe packaging methods and take measures such ascontainer reinforcement to ensure that your goods are delivered to you in good condition.

Project Cases

| Year | Project | End User/ EPC | Site | Material | Products | QTY(KGS) |

| 2019 | CHUNBOTANK | DONGIL | KOREA | N06022 | PLATE/PIPE/TUBE | 20,000 |

| 2019 | Refinery | México | TP347 & TP405 | U TUBE | 80,000 | |

| 2021 | Hart BV/BENVIG HEAT TRANSFER | NETHERLANDS | N06625 | HEAT EXCHANGE TUBE | 30,000 | |

| 2022 | CHUNBO TANK | DONGIL | KOREA | N06022 | PLATE/PIPE/TUBE | 70,000 |

| 2022 | PETROBRAS Buzios P79 FPSO | SAIPEM | SINGAPORE | N06625 | SMLS TUBE | 30,000 |

English

English 中 文

中 文 Español

Español Português

Português Deutsch

Deutsch Türk

Türk Pусский

Pусский عربي

عربي 한국인

한국인 日本語

日本語