ASTM A182 / ASME SA182 600LB F304 / 304L Stainless Steel Socket Welded Flange

MTBWF13

Material: 304H, S30415, 1.4948, S30409; 304L, 1.4306, S30403, 1.4307;

Get Quote

ASTM A182 / ASME SA182 600LB F304 / 304L Stainless Steel Socket Welded Flange

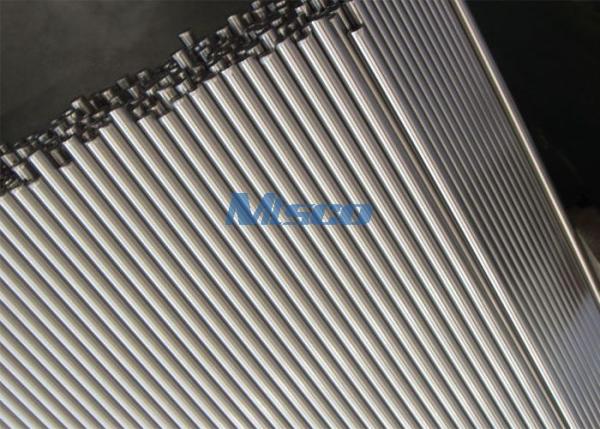

Stainless steel socket welded flange is a tubing fitting used to connect pipes, usually for applications under high pressure or high temperature conditions. It has a raised edge for connection to the end of a pipe and a hole for threading or welding. The orifice is designed to fit directly into the end of the pipe on the pipeline, and the connection is usually secured using a welding method.

This type of flange is usually made of stainless steel and therefore offers excellent resistance to corrosion and high temperatures. The design allows the flange to be attached to the pipe end by welding or threading, providing a reliable seal.

| 1 . Commodity : Welding Neck , Blind , Slip On , Lap Joint , Socket Weld , Threaded , Spectacle Blind , etc |

| 2 . Surfacing : RF , FF , RTJ |

| 3 . Materials : Stainless Steel , Duplex Steel , etc |

| 4 . Standards : ANSI B16.5 , ANSI B 16.47 |

| 5 . Tolerances : according to the specification or customer’s request and drawings |

| 6 . Applications : Pipe connection , Piping project construction etc |

7 . Pressure class : 150 - 2500lbs; class 150-class 2500 |

| 1. Material Grade: WP304 , WP304L , WP304H , WP316 , WP316L , WP316Ti , WP309S , WP310S , WP321 , WP321H , WP347 , WP347H , F304 , F304L , F304H , F316 , F316L , F310S , F321 etc |

| 2. Size: 1/2" to 48" Sch 5S to XXS |

| 3. Standard: ASTM A403 etc . |

| 4. Process Method: Forged / Casting |

Application Areas of Stainless Steel Socket Weld Flange:

Chemical industry: In the chemical industry, these flanges are commonly used to connect various pipes, valves and equipment. Due to the corrosion resistance of stainless steel, they are able to maintain their stability in handling various corrosive media such as acids, alkalis, solvents, and so on.

Oil and Gas Industry: In the oil and gas industry, Stainless Steel Socket Welded Flanges are used to connect oil pipelines, natural gas pipelines and processing equipment. They are able to withstand the demands of high pressure and high temperature conditions to ensure the safe and reliable operation of piping systems.

Food Processing Industry: In the food processing industry, the hygienic and corrosion-resistant properties of stainless steel make these flanges ideal for connecting food processing pipes. They ensure hygiene and safety in the food production process.

Shipbuilding Industry: In the shipbuilding industry, Stainless Steel Socket Welded Flanges are used to connect marine piping systems, including cooling water piping, hydraulic piping and fuel piping. They are able to withstand the corrosion of seawater and the vibration and shock of ship operation.

Pharmaceutical industry: In the pharmaceutical industry, these flanges are commonly used to connect pharmaceutical equipment and piping systems to ensure hygiene and safety in the pharmaceutical process.

ASTM A182 / A182M Standard Chemical Composition :

| Elements | 304L(wt%) / F304L / S30403 | 304(wt%) / F340 / S30400 | 316L (wt%) / F316L /S31603 | 316 (wt%) / F316 / S31600 | 310 (wt%) / F310 / S31000 |

| (C) Carbon, max | 0.03 | 0.08 | 0.03 | 0.08 | 0.25 |

| (Mn) Manganese, max | 2 | 2 | 2 | 2 | 2 |

| (P) Phosphorus, max | 0.045 | 0.045 | 0.045 | 0.045 | 0.045 |

| (S) Sulfur, max | 0.03 | 0.03 | 0.03 | 0.03 | 0.03 |

| (Si) Silicon, max | 1 | 1 | 1 | 1 | 1 |

| (Ni) Nickel | 8.0 - 13.0 | 8.0 - 11.0 | 10.0 - 15.0 | 10.0 - 14.0 | 19.0 - 22.0 |

| (Cr) Chromium | 18.0 - 20.0 | 18.0 - 20.0 | 16.0 - 18.0 | 16.0 - 18.0 | 24.0 - 26.0 |

| (Mo) Molybdenum | N/A | N/A | 2.0 - 3.0 | 2.0 - 3.0 | N/A |

| (Fe) Iron | N/A | N/A | N/A | N/A | N/A |

| (Cu) Copper | N/A | N/A | N/A | N/A | N/A |

| (N) Nitrogen | N/A | N/A | N/A | N/A | N/A |

VIP SERVICE

VR (Virtual) Mill Introduction

Professional Remote Technical Guidanceion

Accept Third-party Inspection

Door to Door Shipment

Get QuoteRelated Products: Flanges: SW TH PL LJ Flanges

Alloy 600 / 601 UNS N06600 / N06601 Nickel Alloy Round Rod / Bar

Material Grade: Alloy C-4/N06455, Alloy B/UNS N10001, Alloy B-2/UNS N10665, Alloy B-3/UNS N10675, Alloy C22/UNS N06022, Alloy 800/N08800, Alloy 825/N08825, Alloy 400/N04400; etc Length:can as per customer's requirement Standard:ASTM B335; ASTM B574; ASTM B572; ASTM B166 etc. MTSCO is a lead......

ASTM B574 / ASME SB574 Alloy C-4 / N06455 Nickel Alloy Round Rod

Material Grade Alloy C-4/N06455, Alloy B/UNS N10001, Alloy B-2/UNS N10665, Alloy B-3/UNS N10675, Alloy C22/UNS N06022,Alloy 800/N08800,Alloy 825/N08825, Alloy 400/N04400; etc Length: can as per customer's requirement Standard: ASTM B335; ASTM B574; ASTM B572; ASTM B166 etc. MTSCO is a leadi......

ASTM A182 F304 / 304L 150-2500LB Stainless Steel Blind Flange FF

MTSCO is a leading manufacturer who is specialized in stainless steel seamless pipes , bright annealed tubes , seamless coiled tubing etc . In order to facilitate customers , we have pipe fittings and flanges too . MTSCO has the most advanced producing and testing equipment . We can totally satisfy ......

English

English 中 文

中 文 Español

Español Português

Português Deutsch

Deutsch Türk

Türk Pусский

Pусский عربي

عربي 한국인

한국인 日本語

日本語