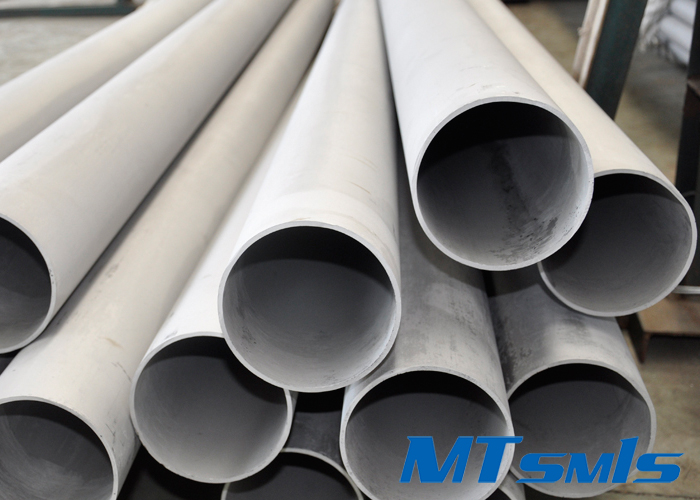

ASTM A312 TP316L/304L Austenitic Stainless Steel Pipe

MTASSP10

Price: From $2900-4900USD/TON

Material: 304, 1.4301, X5CrNi18-10; 304H, S30415, 1.4948, S30409; 304L, 1.4306, S30403, 1.4307; 316L, 1.4401, 1.4404, 1.4435; 310/310S/310H,1.4845;

Get Quote

ASTM A312 / ASME SA312 TP316L / 304L Austenitic Stainless Steel Pipe For Food Industry

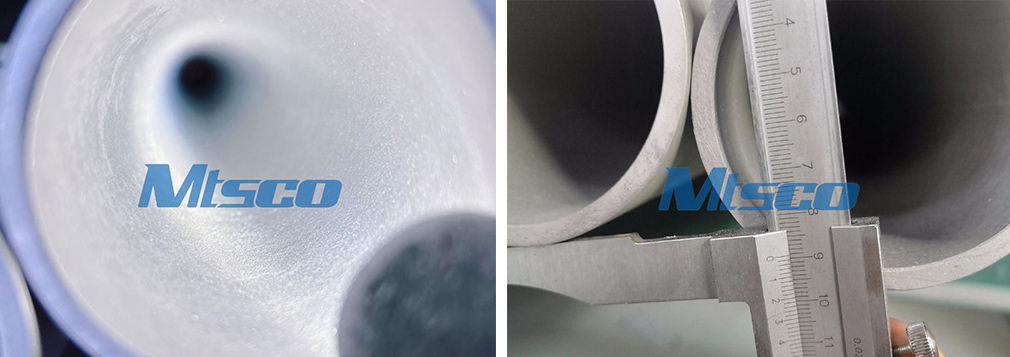

Quality Control of MTSCO Stainless Pipe:

| Grade | Standard | Outside Diameter | 8mm-711mm |

| TP304 TP304L TP316 TP316L TP317L TP321 TP321H TP347 TP347H TP904L | ASTM-A312 ASTM-A790 ASTM-B167/163 ASTM-B444 ASTM-B622 ASTM-B423 EN10216 GOST ...... | Wall Thickness | 1mm-50mm |

| Length | ≤20m | ||

| Inspection | Appearance/ Dimensional test, PMI; NDT: UT/ ET/ HT; Physical & chemical test | ||

| Certificates | ISO/PED/AD2000/TS | ||

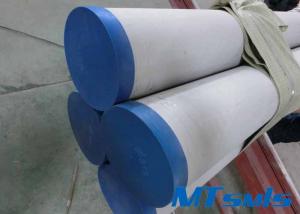

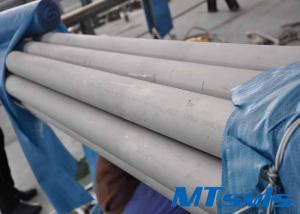

| Package | End protection/ Woven bags/ Wooden cases |

Advantages of Stainless Pipe:

a) Advanced technology of cold draw machine

b) Advanced annealing machine

c) Better mechanical property

d) More precise dimension

e) Perfect inspection method and inspection equipment etc

What is 304 Stainless Pipe?

Why Choose MTSCO Stainless Pipe?

What is the advantage of stainless steel pipe?

Stainless steel pipe play an important role in various industrial fields with their unique advantages and characteristics.

The corrosion resistance of industrial stainless steel pipe is one of its remarkable features. The presence of chromium gives stainless steel pipes a strong resistance to oxidation and corrosion, enabling them to remain stable in harsh chemical environments. This makes stainless steel pipes the first choice for handling corrosive substances, especially in the chemical and petroleum industries, where they are widely used.

The high strength and excellent mechanical properties of stainless steel pipe allow it to excel in high pressure and high temperature environments. Whether in the deep sea wells of oil extraction, or in the high temperature chemical reactor, stainless steel pipe can withstand extreme working conditions, to ensure the reliability and safety of the piping system.

VIP SERVICE

VR (Virtual) Mill Introduction

Professional Remote Technical Guidanceion

Accept Third-party Inspection

Door to Door Shipment

Get QuoteRelated Products: Seamless Pipe: Stainless Steel Seamless Pipe

ASTM A312 S30403 / 1.4306 Stainless Steel Big Size Seamless Pipe For Transportation

MTSCO has been dedicated to producing seamless stainless steel pipe since 2003 , owning complete producing technology and abundant managing experience . Our raw material such as mother tube , round bar we use is from Chinese biggest and well known steel mill : Walsin , Yongxing etc . And We have adv......

DN200 Sch40 S31603 / S30403 Austenitic Annealed & Pickled Stainless Steel Pipe

Annealed pickled pipes are stainless steel pipes treated through annealing and pickling processes. These methods enhance ductility, reduce internal stresses, and create a clean, smooth surface. Ideal for chemical, food, and pharmaceutical industries, these pipes offer improved corrosion resistance a......

EN10216-5 D4 / T3 Plain End Stainless Steel Seamless Pipe , 14 BWG , 18 BWG , 20 BWG

MTSCO has been dedicated to producing seamless stainless steel pipe since 2003 , owning complete producing technology and abundant managing experience . Our raw material such as mother tube , round bar we use is from Chinese biggest and well known steel mill : Walsin , Yongxing etc . And We have adv......

English

English 中 文

中 文 Español

Español Português

Português Deutsch

Deutsch Türk

Türk Pусский

Pусский عربي

عربي 한국인

한국인 日本語

日本語