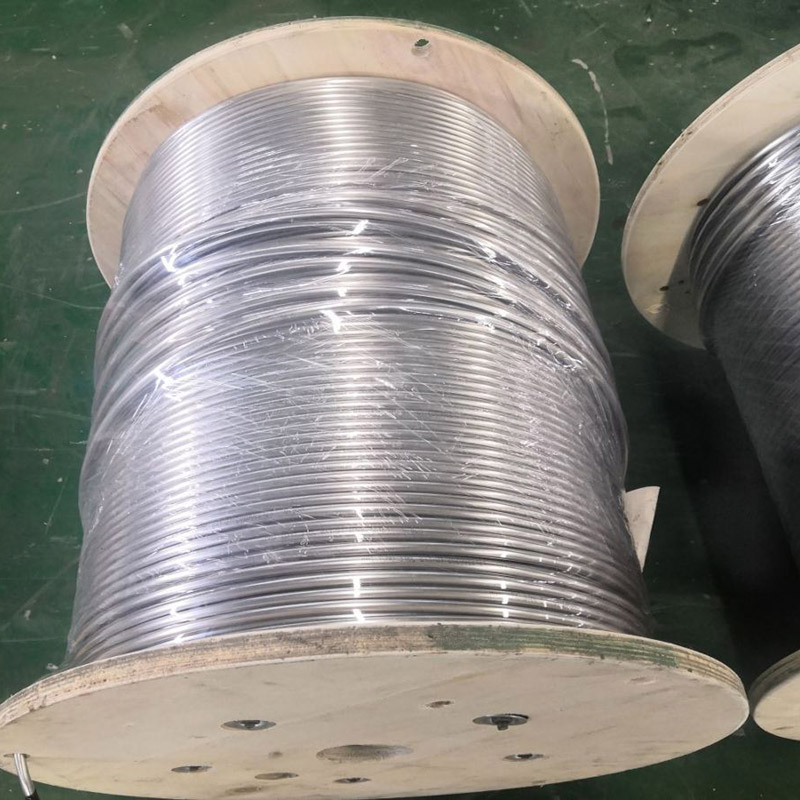

ASTM A789 Tubing, UNS S32750 super duplex steel coil tubing

MT A789/2507

Material: S32750,1.4410, 2507, F53;

Get Quote

ASTM A789 Tubing, UNS S32750 super duplex steel coil tubing oil and gas

2507 Super Duplex is a high alloy duplex stainless steel with a PRE (pitting resistance equivalent) value of 42.5 minimum. The grade is characterized by very good chloride corrosion resistance, combined with very high mechanical strength. It is particularly suited for use in aggressive environments such as warm chlorinated seawater and acidic chloride-containing media. It is widely used in offshore oil and gas exploration/production and in heat exchangers in petrochemical/chemical processing. The grade is also suitable for hydraulic and instrumentation applications in tropical marine environments.

|  |

Specification:

Material: TP316/L, TP304/L, S32205, S32750, Alloy 825/N08825, Alloy 400/ N04400, Alloy 625/ N06625

Type: Welded

Hole count: Single/Multi Core

Outer Diameter: 4mm-88.9mm

Wall Thickness: 0.3mm-2.5mm

Length : According to customers’ needs, up to 33000fts

Standard: ASTM A269/A213/A789/B704/B163,etc.

Certificate: ISO/CCS/DNV/BV/ABS, etc.

Inspection: NDT; Hydrostatic test

Package: Wooden or iron reel

Chemical composition:

| UNS Designation | C | Si | Mn | P | S | Cr | Ni | Mo | N | Cu |

| max | max | max | max | max | ||||||

| S31803 | 0.03 | 1 | 2 | 0.03 | 0.02 | 21.0 - 23.0 | 4.5 - 6.5 | 2.5 - 3.5 | 0.08 - 0.20 | - |

| 2205 | ||||||||||

| S32205 | 0.03 | 1 | 2 | 0.03 | 0.02 | 22.0 - 23.0 | 4.5 - 6.5 | 3.0 - 3.5 | 0.14 - 0.20 | - |

| S32750 | 0.03 | 0.8 | 1.2 | 0.035 | 0.02 | 24.0 - 26.0 | 6.0 - 8.0 | 3.0 - 5.0 | 0.24 - 0.32 | 0.5 max |

| 2507 | ||||||||||

| S32760 | 0.05 | 1 | 1 | 0.03 | 0.01 | 24.0 - 26.0 | 6.0 - 8.0 | 3.0 - 4.0 | 0.20 - 0.30 | 0.50 -1.00 |

Physical property:

| Steel grade | Physical Property | |||

| Y.S | T.S | EL. | HRB | |

| S31803 | ≥450 | ≥620 | ≥25 | - |

| S32205/2205 | ≥450 | ≥620 | ≥25 | - |

| S32750/2507 | ≥550 | ≥800 | ≥15 | ≤32 |

| S32760 | ≥550 | ≥750 | ≥45 | ≤29 |

Benefits Of Coil Tubing:

The traditional method is to weld the ends of long pipes to ends or with fittings, which is a very labor-intensive process, and the welding process is time-consuming and costly.

1. Corrosion resistance is enhanced due to the properties of stainless steel, duplex steel and nickel alloys.

2. Improved reliability - fewer mechanical parts or welds are used, reducing the chance of defects such as leaks and other long-term failures.

3. Reduce installation labor costs - installing a continuous section of pipeline takes less time and is more reliable than connecting multiple shorter sections of pipeline.

Our strengths:

First, MTSCO welded coiled tubing can be up to 33,000fts per coil.

Second, the welded coiled tubing can pass the max hydraulic pressure of 100MPA.

Third, the seamless coiled tubing can be up to 120kgs per coil.

Fourth, we can provide various encapsulated plastic material.

Fifth, MTSCO coiled tubing have obtained ISO/PED certificate.

|  |

Quality control:

1. Quality control of raw materialsFirst, secondary inspection of raw materials.Our raw materials come from large factories such as Baosteel, TSINGSHAN, WALSIN, POSCO,JISCO, ANSTEEL, ATI...Each batch of raw materials requires MTC and PMI. After the raw materials arrive, we conduct PMI and other inspections again to ensure that they meet the requirements.

2. Quality control during productionSecond, traceability of the production process.The mainly production process includes welding, cold drawing, bright annealing and plastic wrapping.

Each process is supervised by experienced engineers and technicians. Each link is supervised by professional qc inspectors and photographed for archiving. The entire process uses process cards to ensure accuracy and traceability.

3. Quality control before shipmentThird, 100% inspection before shipment.MTSCO has professional QC team to conduct a series of inspections and experiments on the tubes, including routine appearance, PMI, size, quantity, and other inspections. At the same time, we also conducts mechanical testing, hardness testing, airtightness,UT, ET, HT and other tests. Among them, welded coiled tubing can pass the max hydraulic pressure of 100MPA.

In addition, we also accept third-party inspection, such as SGS, TUV, and BV.

Application Areas:

Chemical Processes:Super Duplex Steel 2507 is designed for demanding applications requiring extremely high strength and corrosion resistance for chemical processes, petrochemical and seawater equipment. The alloy is used in salt evaporation processes, heat exchangers and hydrochloric acid environments.

Marine: Ocean transportation spends much of its time at sea, and 2507 offers excellent resistance to seawater hardness. Ships need the corrosion resistance of Super Duplex 2507 to stay on schedule. Marine applications include piping for desalination plants and ship propulsion systems.

Oil & Gas: Super Duplex Stainless Steel 2507 is known for its superior performance, strength and corrosion resistance, making it the perfect choice for offshore oil and gas exploration and production applications.

Power Generation: The mechanical and corrosion properties of Super Duplex Stainless Steel 2507 make it an economical choice for reheater piping in flue gas desulfurization units.

Pulp and Paper: Super Duplex 2507 has excellent resistance to chloride pitting and crevice corrosion for use in chloride-containing bleaching environments and oxygen delignification.

Renewable Energy: Properties such as strength, good ductility and excellent corrosion resistance make 2507 alloy an ideal solution for heat exchangers in geothermal wells and production tubing.

VIP SERVICE

VR (Virtual) Mill Introduction

Professional Remote Technical Guidanceion

Accept Third-party Inspection

Door to Door Shipment

Get QuoteRelated Products: Coiled Tubing, Control Line: Welded / Seamless Coiled Tubing

Downhole Tools TP316/TP316L Seamless Stainless Steel Coiled Tubing

Maybe someone also calls it control line, capillary tubing, downhole tubing, chemical injection tubing, etc. Because the welded coiled tubing can be used in a variety of applications.Such as Marine, oil and gas, downhole, heat exchanger......

15.88mmx1.24mm stainless steel seamless tubing

Type of Stainless Steel Coiled Tubing Stainless steel industry tubing, Super-long coiled tubing, U bend tubing, Pressure tubing, Heat exchanger tubing, Fluid pipe, Spiral pipe etc. High-temperature resistance, Impact resistant and corrosion, Ammonia corrosion resistant Anti-fouling, Dirt-re......

ASTM A213 TP304L 1/4 Inch Bright Annealed Instrument Coiled Tube

As one of the leading manufacturer in stainless steel industry, seamless coiled tubing are our best competitive products. We have the most advanced producing and testing equipments, also have the biggest production scale. Products will be do PMI, NDT tests before they have been sent to our cli......Coiled Tubing for Heat exchanger

Advantage: Seamless Coiled Tubing can be anti impact corrosion, anti ammonia corrosion, anti fouling, not easy to get stain, anti-oxidation corrosion, having long lifetime, saving the time of maintenance, saving costs, having good tubing technology, higher pressure capacity and safety reliable. A......Get Quote

*Your email address will not be published. Required fields are marked.

English

English 中 文

中 文 Español

Español Português

Português Deutsch

Deutsch Türk

Türk Pусский

Pусский عربي

عربي 한국인

한국인 日本語

日本語