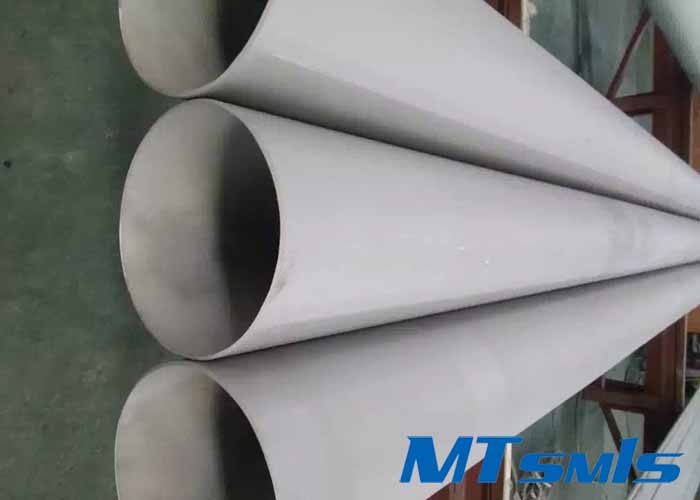

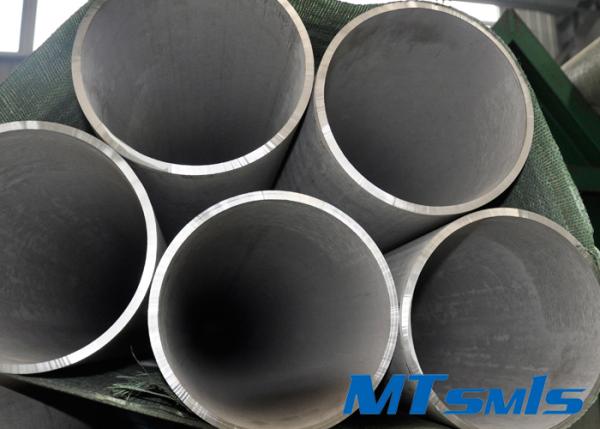

ASTM A790 / ASTM SA790 S32205 / S31803 F51 Duplex Steel Pipe With PE / BE End

SSDSP32

Price: From $5000-7000USD/TON

Material: S32205, S31803, 1.4462;

Get Quote

ASTM A790 / ASTM SA790 S32205 / S31803 F51 Duplex Steel Pipe With PE / BE End

Duplex stainless steel that was developed to combat common corrosion problems encountered with the 300 series stainless steels . “ Duplex ” describes a family of stainless steels that are neither fully austenitic , like 304 stainless , nor purely ferritic , like 430 stainless . The advantage of a duplex structure is that it combines the favorable qualities of a ferritic alloy ( stress corrosion cracking resistance and high strength ) with those of an austenitic alloy ( ease of fabrication and corrosion resistance ) .

Use UNS32750 super duplex stainless steel pipes can improve corrosion resistance compared to other materials . And super duplex steel pipes have greater tensile and yield strength , good ductility and yield strength , good stress corrosion cracking resistance . Also can help clients reduce their purchase costs , but can gurantee the quality etc .

| Material Grade | S32205 , S31803 , S32304 , S32750, F51 , F53 , 2205 , 2507 etc |

| Outer Diameter | 10.3mm - 1219mm |

| Wall Thickness | 1.24mm - 54.59mm |

| Length | as per customer's requirement |

| Standard | ASTM A789 ; ASTM A790 ; EN 10216-5 etc. |

Price Item: FOB, CFR, CIF or as negotiation

Payment: T/T, LC or as negotiation

Delivery Time: 30 working days after received your deposit (Normally according to the order quantity)

Package: Iron case; woven bag or as per customer’s requirement

Requirement: Mill Test Certificate will be supplied with shipment, Third Part Inspection is acceptable

Quality Test: NTD(Ultrasonic test, Eddy Current test);

Mechanical Test(Tension Test, Flaring Test, Flattening Test, Hardness Test, Hydraulic test);

Metal Test(Metallographic Analysis, Impact Test-High/low temperature);

Chemical Analysis(Photoelectric Emission Spectroscopic)

Main Market: Europe, Middle East, Southeast Asia, South America. Etc

| UNS Designation | C | Si | Mn | P | S | Cr | Ni | Mo | N | Cu |

| max | max | max | max | max | ||||||

| S31803 | 0.03 | 1 | 2 | 0.03 | 0.02 | 21.0 - 23.0 | 4.5 - 6.5 | 2.5 - 3.5 | 0.08 - 0.20 | - |

| S32205 | 0.03 | 1 | 2 | 0.03 | 0.02 | 22.0 - 23.0 | 4.5 - 6.5 | 3.0 - 3.5 | 0.14 - 0.20 | - |

| S32750 | 0.03 | 0.8 | 1.2 | 0.035 | 0.02 | 24.0 - 26.0 | 6.0 - 8.0 | 3.0 - 5.0 | 0.24 - 0.32 | 0.5 max |

| S32760 | 0.05 | 1 | 1 | 0.03 | 0.01 | 24.0 - 26.0 | 6.0 - 8.0 | 3.0 - 4.0 | 0.20 - 0.30 | 0.50 -1.00 |

Application

a) Petroleum

b) Chemical industry

c) Instrument

d) Industrial transportation

e) Mechanical structure industry

f) Need high corrision ability pipe's industry, such as offshore industry etc

Advantages

a) Superior surface finish,

b) Better mechanical property

c) More precise dimension

d) Perfect inspection method and inspection equipment

VIP SERVICE

VR (Virtual) Mill Introduction

Professional Remote Technical Guidanceion

Accept Third-party Inspection

Door to Door Shipment

Get QuoteRelated Products: Seamless Pipe: Duplex Steel Seamless Pipe

8 Inch Sch40s Duplex Steel Seamless Pipe Big Size SAF2205 / 2507

Duplex stainless steel that was developed to combat common corrosion problems encountered with the 300 series stainless steels . Duplex describes a family of stainless steels that are neither fully austenitic , like 304 stainless , nor purely ferritic , like 430 stainless . The advantage of a duplex......

ASTM A790 / A789 F51 / F53 Annealed & Pickled Duplex Steel Seamless Pipe

Duplex stainless steel that was developed to combat common corrosion problems encountered with the 300 series stainless steels . Duplex describes a family of stainless steels that are neither fully austenitic , like 304 stainless , nor purely ferritic , like 430 stainless . The advantage of a duplex......

SAF 2507 / 1.4410 Duplex Steel Pipe Corrosion Resistance With Fixed Length

Material Grade: S32205 , S31803 , S32304 , S32750, F51 , F53 , 2205 , 2507 etc Outer Diameter: 10.3mm - 1219mm Wall Thickness: 1.24mm - 59.54mm Length: as per customer’s requirement Standard: ASTM A789 ; ASTM A790 ; EN 10216-5 etc SAF 2507 / 1.4410 is a super duplex stainless steel with ......

English

English 中 文

中 文 Español

Español Português

Português Deutsch

Deutsch Türk

Türk Pусский

Pусский عربي

عربي 한국인

한국인 日本語

日本語