Boom!Explosive welding, have you ever seen it?

The explosive welding was first proposed by Carl in 1944. He first observed the solid state welding of materials caused by explosive detonation under high-speed collision, and proposed the idea of welding all kinds of metals together by using explosion and ultrasonic technology. Then philipchuk V of the United States introduced explosive welding technology into the real industry for the first time, and successfully realized the explosive welding between aluminum and steel.

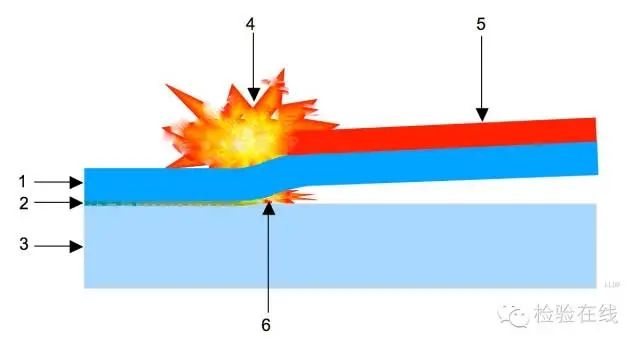

1. cover plate; 2. fusion zone; 3. base plate; 4. explosion; 5. explosive; 6. jet flow

Advantages of explosive welding

(1) The connection of the same and different metal materials can be realized;

(2) The welding size range is wide (the weldable area is 13-28m2);

(3) It can be welded with double layer and multi-layer plate;

(4) The technology is simple, it does not need complex equipment, less investment and convenient application;

(5) It can save precious metals without filling metal;

(6) The surface cleaning requirements are not high, so it is necessary to remove oxide scale and oil pollution.

Defects of explosive welding

(1) The metal materials welded must have enough toughness and impact resistance to withstand the violent impact of explosion force;

(2) The metal is sprayed during explosive welding, which is only used for plane and cylinder welding, and it is not suitable for complex structure welding;

(3) The field open-air operation, the mechanization degree is low, the labor condition is poor;

(4) Noise and air waves are produced, which have an impact on the surrounding environment.

Is it a good welding method? Hope our products have a chance to try once!

English

English 中 文

中 文 Español

Español Português

Português Deutsch

Deutsch Türk

Türk Pусский

Pусский عربي

عربي 한국인

한국인 日本語

日本語