ASTM A213 TP304/304L/TP316/316L/316Ti Seamless Coiled Tubing

SSSCT18

Material: 304, 1.4301, X5CrNi18-10; 304L, 1.4306, S30403, 1.4307; 316L, 1.4401, 1.4404, 1.4435;

Get Quote

Bright Annealed Stainless Steel Coiled Tubing Seamless Tube For Industry

Stainless Steel Coiled Tubing:

stainless steel coiled tubing is a kind of pipe that can be widely used in petrochemical, electric power, nuclear industry, medicine, food, and other industries.

stainless steel coiled tubing is very rich in variety, including stainless steel industrial tube, super long coiled tube, U-shaped tube, pressure tube, heat exchanger tube, fluid tube, spiral coiled tube, multi-core tube, cable ducts, and so on.

Stainless Steel Coiled Tubing Material Grade :

Grade

| TP304/304L/316/316L(300 series are the main products, if you have special material requirements, please tell us) |

Standard | ASTM A 213,ASTM A 269,EN10216-5 |

Size | OD:4.76-25.4mm WT:0.71-2.11mm Length:>1000Meters |

Advantage | 1. Improve the security(one mother tube make up it, no welds) 2. Reduce your cost (length can reach more than 1000 meters, highly reduces total cost during installation) 3. Compact package for shipment and storage(easier in container) |

Application | 1. Control Tubing in Oil and Gas Well 2. Instrument Tubing 3. Chemical Injection Tubing Line 4. Pre-insulated Tubing 5. Electric Heating or Steam Heating Tubing Line 6. Heater Tubing Line etc |

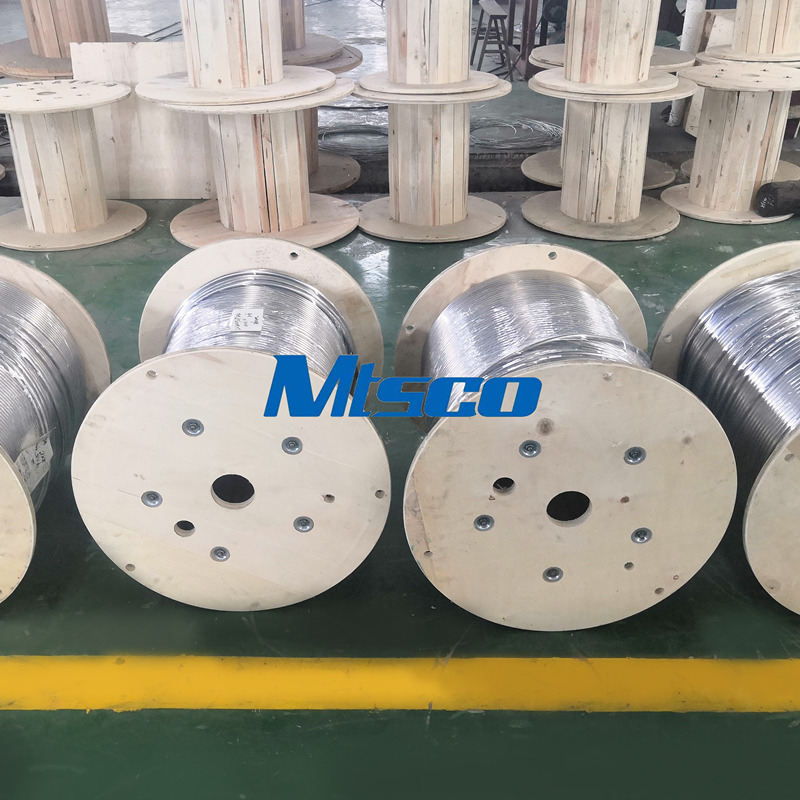

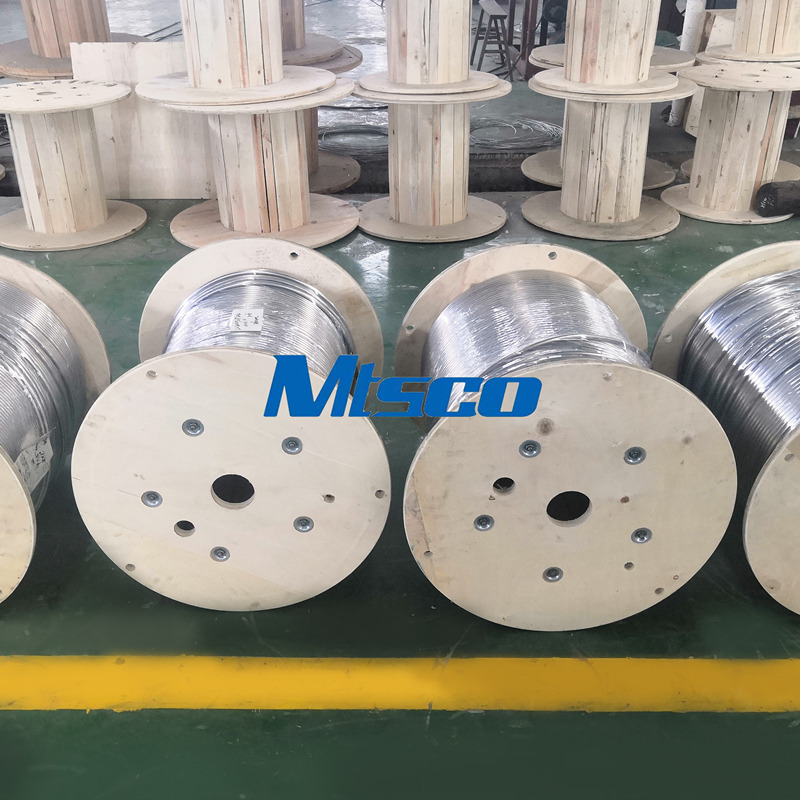

Package | Level wound, the smaller dimensions level wound on wooden or plastic spools per coil, the packed by plywood case 1. Plywood case 2. Wooden spools 3. Woven bags |

Stainless Steel Coiled Tubing Performance Testing:

| 1 | 100% PMI, Spectro Chemical Analysis Test For Raw Material |

| 2 | 100% Dimension & Visual Examination |

| 3 | Mechanical Properties Test Include Tension Test, Flaring Test ( For Seamless Tube / Pipe ), Hardness Test, Reversed Flattening Test |

| 4 | 100% Hydrostatic Test Or 100% Non-Destructive Test (ET Or UT) |

| 5 | Straightness Test ( Optional ) |

| 6 | Roughness Test ( Optional ) |

| 7 | Intergranular Corrosion Test ( Optional ) |

| 8 | Impact Test ( Optional ) |

| 9 | Grain Size Determinations ( Optional ) |

| 10 | All The Tests And Inspection Result Need To Be Showed In Reports Accordance To Standard And Specification. |

VIP SERVICE

VR (Virtual) Mill Introduction

Professional Remote Technical Guidanceion

Accept Third-party Inspection

Door to Door Shipment

Get QuoteRelated Products: Coiled Tubing, Control Line: Welded / Seamless Coiled Tubing

ASTM A213 / A269 S30400 / S31600 Stainless Steel Welded Super Long Coiled Tube

Material Grade : American Standard: TP304 , TP304L , TP310S , TP316 , TP316L , TP316Ti , TP321 , TP347 , 904L Etc European Standard: 1.4301 , 1.4306 , 1.4845 , 1.4401 , 1.4404 , 1.4571 , 1.4541 , 1.4550 , 1.4539 Etc German Standard: X5CrNi18-10 , X2CrNi19-11 , X12CrNi25-21 , X5CrNi17-12-2 , X......Coiled Tubing for Heat exchanger

Advantage: Seamless Coiled Tubing can be anti impact corrosion, anti ammonia corrosion, anti fouling, not easy to get stain, anti-oxidation corrosion, having long lifetime, saving the time of maintenance, saving costs, having good tubing technology, higher pressure capacity and safety reliable. A......

ASTM A213 6.35mm TP304L Stainless Steel Super Long Coiled Tube For Control Line

Material Grade : American Standard: TP304 , TP304L , TP310S , TP316 , TP316L , TP316Ti , TP321 , TP347 , 904L Etc European Standard: 1.4301 , 1.4306 , 1.4845 , 1.4401 , 1.4404 , 1.4571 , 1.4541 , 1.4550 , 1.4539 Etc German Standard: X5CrNi18-10 , X2CrNi19-11 , X12CrNi25-21 , X5CrNi17-12-2 , ......

English

English 中 文

中 文 Español

Español Português

Português Deutsch

Deutsch Türk

Türk Pусский

Pусский عربي

عربي 한국인

한국인 日本語

日本語