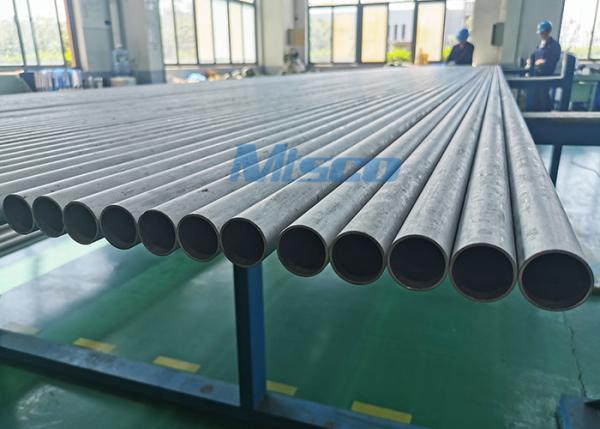

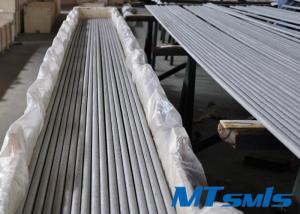

Duplex steel tube

SSDST09

Material: S32205, S31803, 1.4462; S32304, 1.4362, UNS S32304; S32750,1.4410, 2507, F53; S32760, 1.4501;

Get QuoteDuplex steel tube

01. Process method: cold drawn/cold pilger.

02. Surface finish: annealed/ cold pilger,polish etc.

03. Size: (ansi/asme size as under, other standards of size is for ready choice):

(a). O.D.: 3/8" to 10" ()

(b). W.T.: 0.04" to 0.8"()

04. Length: Max. 24 meters.

05. Delivery conditions: annealed & pickled.

06. Applications: for fluid and gas transport; structure and machining.

07. Packing: plastic bag for each piece then packed in seaworthy wooden cases.

Usage:

Heat exchanger and tube on oil desalt device, catalyst tubebank of tubular reactor for methanol manufacturing, precondenser for VCM, convey pipe and header of land/ocean oil/gas industry; heat exchanger, water treatment and supply system, fire extinguishing system, spraying system and water stablizing system of onsea petrol platform; pressure vessel, chanels, tanks, and heat exchanger used in chemicals process and transportation in chemical industry.

General characteristic

High intensity and tenacity, excellent mechnical performance.

Good resistance to corrosive pitting and crevice corrosion.

Good resistance to stress corrosion craking.

Good resistance to uniform corrosion.

The material has bigger heat conductiovity, and smaller linear exppansibility.

Good welding performance, small tendency of hot cracking.

VIP SERVICE

VR (Virtual) Mill Introduction

Professional Remote Technical Guidanceion

Accept Third-party Inspection

Door to Door Shipment

Get QuoteRelated Products: Seamless Tube: Annealed Pickled Heat Exchanger Tube

ASTM A213 / ASTM A269 Small Diameter TP304L Heat Exchanger Stainless Steel Tube For Fluid And Gas

Heat exchanger tubes are precision manufactured using techniques such as cold drawing and precision moulding, and these tubes are often subjected to rigorous testing - hydrotesting or pneumatic testing - to ensure that they can withstand the pressures of real-world applications. These tubes are cri......

DN80 ASTM A789 / A790 Annealed & Pickled Duplex Steel Pipe

Description : 1 . Outer Diameter : 10.3mm -1219mm Material Grade : S32205 , S31803 , S32304 , S32750, F51 , F53 , F55 , F61 , 2205 , 2507 Etc 2 . Wall Thickness :1.24mm - 59.54mm 3 . Length : As per customer's requirement 4 . Standard : ASTM A789 ; ASTM A790 ; EN 10216-5 etc. Wel......

English

English 中 文

中 文 Español

Español Português

Português Deutsch

Deutsch Türk

Türk Pусский

Pусский عربي

عربي 한국인

한국인 日本語

日本語