FDSiMn/ TDSiMn Oil Quenched-tempered Spring Wire With Good Thermal Stability

Get Quote

FDSiMn/ TDSiMn Oil Quenched-tempered Spring Wire With Good Thermal Stability

| Product Name | Oil Quenched-tempered Spring Steel Wire | |||

| Material | 65Mn, 70#, 72A, 72B, 55SiCr, 50CrVA, 60Si2MnA, 65Si2CrV, SAE9254, etc. | |||

| Use | Clutch spring, suspension spring, valve spring, etc. | |||

| Standard | GTB/18983-2017, EN10270-2, DIN17223-2, ASTMA229/A230/A401/A877, JSG3560/3561, etc. | |||

| Diameter | φ1.8mm -φ16mm | |||

| Cross section | Special-shaped steel bars with circular and various non-circular sections | |||

Oil quenching - tempering: A wire that is drawn to the finished size and quenched and tempered in a continuous furnace. The unwound wire is first heated to full austenitizing temperature in a continuous furnace and then quenched by oil bath Martensite, and then through the continuous furnace tempering, to obtain the expected strength and toughness. Oil quenching - tempering steel wire straightness is good, the uniformity of mechanical properties, made of components or components only after low temperature stress treatment that can be used directly.

Application:

VDSiCr, VDSiCrV: Wire for alloy and non-alloy steel springs for use with severe dynamic stresses, such as springs for valves.

| Grades | C | Si | Mn | Cr | V | P | S | Other elements | Standard |

| FDC (60~75Mn) | 0.60~0.75 | 0.10~0.35 | 0.50~1.20 | - | - | ≤0.030 | ≤0.030 | Cu≤0.20 | GB/T18983 -2003 |

| TDC ,VDC (60~75Mn) | 0.60~0.75 | 0.10~0.35 | 0.50~1.20 | - | - | ≤0.020 | ≤0.025 | Cu≤0.12 | GB/T18983 -2003 |

| 50CrVA (FDCrV-A,TDCrV-A) | 0.47~0.55 | 0.10~0.40 | 0.60~1.20 | 0.80~~1.10 | 0.15~0.20 | ≤0.030 | ≤0.030 | Cu≤0.20 | GB/T18983 -2003 |

| VDCrV-A(50CrVA) | 0.47~0.55 | 0.10~0.40 | 0.60~1.20 | 0.80~1.10 | 0.15~0.25 | ≤0.025 | ≤0.025 | Cu≤0.12 | GB/T18983 -2003 |

| 67CrVA (FDCrV-B,TDCrV-B) | 0.62~0.72 | 0.15~0.30 | 0.50~0.90 | 0.40~0.60 | 0.15~0.25 | ≤0.030 | ≤0.030 | Cu≤0.20 | GB/T18983 -2003 |

| VDCrV-B(67CrVA) | 0.62~0.72 | 0.15~0.30 | 0.50~0.90 | 0.40~0.60 | 0.15~0.25 | ≤0.025 | ≤0.025 | Cu≤0.12 | GB/T18983 -2003 |

| FDSiMn,TDSiMn (60SiMn) | 0.56~0.64 | 1.50~2.00 | 0.60~0.90 | ≤0.035 | ≤0.035 | Cu≤0.25 | GB/T18983 -2003 | ||

| 55CrSiA (FDCrSi,TDCrSI) | 0.50~0.60 | 1.20~1.60 | 0.50~0.90 | 0.50~0.80 | ≤0.030 | ≤0.030 | Cu≤0.20 | GB/T18983 -2003 | |

| VDCrSi(55CrSiA) | 0.50~0.60 | 1.20~1.60 | 0.50~0.90 | 0.50~0.80 | ≤0.025 | ≤0.025 | Cu≤0.12 | EN10270-2:2011 | |

| FDCrSiV(60CrSiVA) | 0.50~0.70 | 1.20~1.65 | 0.40~0.90 | 0.50~1.00 | 0.10~0.25 | ≤0.030 | ≤0.025 | Cu≤0.12 | EN10270-2:2011 |

| TDCrSIV(60CrSiVA) | 0.50~0.70 | 1.20~1.65 | 0.40~0.90 | 0.50~1.00 | 0.10~0.25 | ≤0.020 | ≤0.020 | Cu≤0.10 | EN10270-2:2011 |

| VDCrSiV(60CrSiVA) | 0.50~0.70 | 1.20~1.65 | 0.40~0.90 | 0.50~1.00 | 0.10~0.25 | ≤0.020 | ≤0.020 | Cu≤0.06 | EN10270-2:2011 |

|  |

| Mechanical properties of static and medium fatigue steel wire | ||||||||

| Diameter range/mm | Tensile strength Rm/MPa | Section shrinkage | ||||||

| Z°/% | ||||||||

| FDC | FDCrV-A | FDSiMn | FDSiCr | TDSiCr-B | TDSiCr-C | FD | TD | |

| TDC | TDCrV-A | TDSiMn | TDSiCr-A | |||||

| 0.50-0.80 | 1800-2100 | 1800-2100 | 1850-2100 | 2000-2250 | — | — | — | |

| >0.80-1.00 | 1800-2060 | 1780-2080 | 1850-2100 | 2000-2250 | — | — | — | |

| >1.00-1.30 | 1800-2010 | 1750-2010 | 1850-2100 | 2000-2250 | — | — | 45 | 45 |

| >1.30-1.40 | 1750-1950 | 1750-1990 | 1850-2100 | 2000-2250 | — | — | 45 | 45 |

| >1.40-1.60 | 1740-1890 | 1710-1950 | 1850-2100 | 2000-2250 | — | — | 45 | 45 |

| >1.60-2.00 | 1720-1890 | 1710-1890 | 1820-2000 | 2000-2250 | — | — | 45 | 45 |

| >2.00-2.50 | 1670-1820 | 1670-1830 | 1800-1950 | 1970-2140 | — | — | 45 | 45 |

| >2.50-2.70 | 1640-1790 | 1660-1820 | 1780-1930 | 1950-2120 | — | — | 45 | 45 |

| >2.70-3.00 | 1620-1770 | 1630-1780 | 1760-1910 | 1930-2100 | — | — | 45 | 45 |

| >3.00-3.20 | 1600-1750 | 1610-1760 | 1740-1890 | 1910-2080 | — | — | 40 | 45 |

| >3.20-3.50 | 1580-1730 | 1600-1750 | 1720-1870 | 1900-2060 | — | — | 40 | 45 |

| >3.50-4.00 | 1550-1700 | 1560-1710 | 1710-1860 | 1870-2030 | — | — | 40 | 45 |

| >4.00-4.20 | 1540-1690 | 1540-1690 | 1700-1850 | 1860-2020 | — | .— | 40 | 45 |

| >4.20-4.50 | 1520-1670 | 1520-1670 | 1690-1840 | 1850-2000 | — | — | 40 | 45 |

| >4.50-4.70 | 1510-1660 | 1510-1660 | 1680-1830 | 1840-1990 | — | — | 40 | 45 |

| >4.70-5.00 | 1500-1650 | 1500-1650 | 1670-1820 | 1830-1980 | — | — | 40 | 45 |

| >5.00-5.60 | 1470-1620 | 1460-1610 | 1660-1810 | 1800-1950 | — | — | 35 | 40 |

| >5.60-6.00 | 1460-1610 | 1440-1590 | 1650-1800 | 1780-1930 | — | — | 35 | 40 |

| >6.00-6.50 | 1440-1590 | 1420-1570 | 1640-1790 | 1760-1910 | — | — | 35 | 40 |

| >6.50-7.00 | 1430-1580 | 1400-1550 | 1630-1780 | 1740-1890 | — | — | 35 | 40 |

| >7.00-8.00 | 1400-1550 | 1380-1530 | 1620-1770 | 1710-1860 | — | — | 35 | 40 |

| >8.00-9.00 | 1380-1530 | 1370-1520 | 1610-1760 | 1700-1850 | 1750-1850 | 1850-1950 | 30 | 35 |

| >9.00-10.00 | 1360-1510 | 1350-1500 | 1600-1750 | 1660-1810 | 1750-1850 | 1850-1950 | 30 | 35 |

| >10.00-12.00 | 1320-1470 | 1320-1470 | 1580-1730 | 1660-1810 | 1750-1850 | 1850-1950 | 30 | 35 |

| >12.00-14.0 | 1280-1430 | 1300-1450 | 1560-1710 | 1620-1770 | 1750-1850 | 1850-1950 | 30 | 35 |

| >14.0-15.00 | 1270-1420 | 1290-1440 | 1550-1700 | 1620-1770 | 1750-1850 | 1850-1950 | 30 | 35 |

| >15.00-17.00 | 1250-1400 | 1270-1420 | 1540-1690 | 1580-1730 | 1750-1850 | 1850-1950 | 30 | 35 |

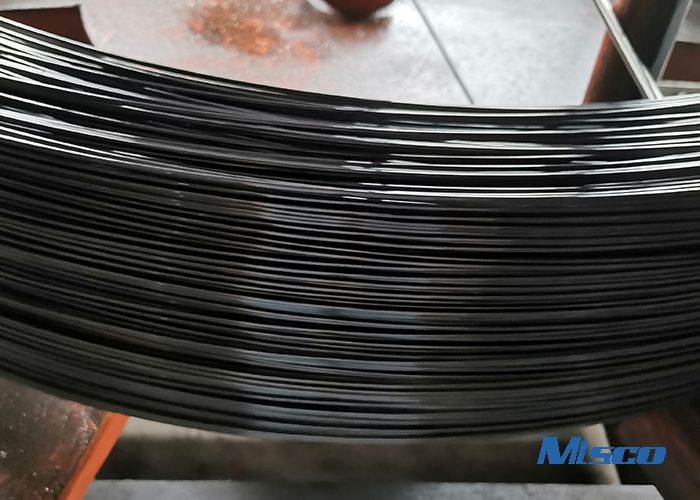

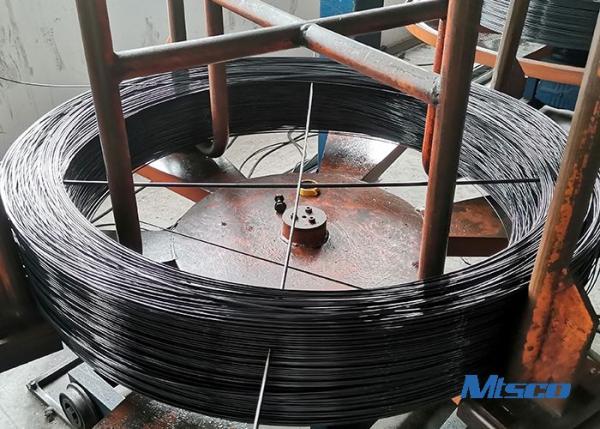

Production process for oil quenched-tempered spring wire:

MTSCO is a professional supplier of steel wire with complete production technology and rich management experience. We produce spring wire, electrolytic polished wire, fine wire, wire for netting, hose wire, welding wire, cold heading, locking wire, and other products. Our main materials are stainless steel and alloy steel, and the raw materials we use are from the biggest and most well-known steel mills in China, we can supply wire in sizes ranging from 0.15 mm to 16 mm in diameter. Our factory is well-equipped and our products conform to ASTM, DIN, GTB, JIS, JSG, and other international standards. We have experienced foreign trade staff with high-quality service and can produce high-quality products according to customers' requirements.

VIP SERVICE

VR (Virtual) Mill Introduction

Professional Remote Technical Guidanceion

Accept Third-party Inspection

Door to Door Shipment

Get QuoteRelated Products: Steel Wire: Carbon Steel Wire

ASTM A229 65Mn Spring Steel Wire Oil Quenched-tempered With High Toughness

MTSCO is a professional supplier of steel wire with complete production technology and rich management experience. We produce spring wire, electrolytic polished wire, fine wire, wire for netting, hose wire, welding wire, cold heading, locking wire, and other products. Our main materials are stainles......

ASTM A229/229 UNS 1065 Carbon Steel Spring Wire for Automotive Manufacturing

Carbon steel spring wire is a high strength spring material with excellent mechanical properties, high tensile strength and good elasticity. Its stable and reliable performance, excellent durability and flexible processing make it suitable for manufacturing high-quality springs. This type of spring ......

60Si2MnA/ 65Si2CrV ASTM A401 Alloy Steel Spring Wire With High Fatigue Limit

MTSCO is a professional supplier of steel wire with complete production technology and rich management experience. We produce spring wire, electrolytic polished wire, fine wire, wire for netting, hose wire, welding wire, cold heading, locking wire, and other products. Our main materials are stainles......

English

English 中 文

中 文 Español

Español Português

Português Deutsch

Deutsch Türk

Türk Pусский

Pусский عربي

عربي 한국인

한국인 日本語

日本語