Main Factors Affecting Stainless Steel Flange Sealing Performance

Bolt preload

The preload must compress the gasket to achieve the initial seal. Properly increasing the bolt preload can increase the sealing capacity of the gasket, because increasing the preload can keep a large contact surface specific pressure of the gasket under normal working conditions.

However, the preload should not be too large, otherwise the gasket will yield as a whole and lose its resilience, or even extrude or crush the gasket. In addition, the preload shall act on the gasket as evenly as possible. Generally, measures such as reducing the bolt diameter, increasing the number of bolts and taking appropriate pre tightening methods are taken to improve the sealing performance.

Gasket performance

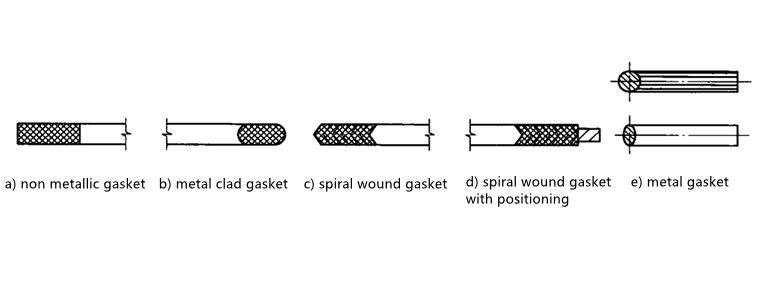

Gasket is an important component of seal, and its main types are shown in the figure below.

The gasket is used to seal the gap between the two stainless steel flange sealing surfaces and prevent fluid leakage. The types of gaskets include non-metallic gaskets, non-metallic and metal combined gaskets and metal gaskets.

Suitable gasket material requires that the gasket can produce necessary elastic deformation without being crushed or extruded under the action of appropriate preload; During operation, the distance between the stainless steel flange sealing surface is enlarged, and the gasket material shall have sufficient resilience to make the gasket surface in close contact with the flange surface, so as to continue to maintain good sealing performance;

Stainless Steel Flange Sealing surface type

The contact surface between stainless steel flange with gaskets and pressed tightly is called flange sealing surface. The selection of sealing surface type is related to the operating conditions, the consequences of leakage and the properties of gasket. The most common structural types are plane sealing surface, concave convex sealing surface, tenon groove sealing surface, trapezoidal groove sealing surface and conical sealing surface.

The roughness of flange sealing surface shall match the requirements of gasket. Radial knife marks or scratches are not allowed on the surface, and surface cracks are not allowed.

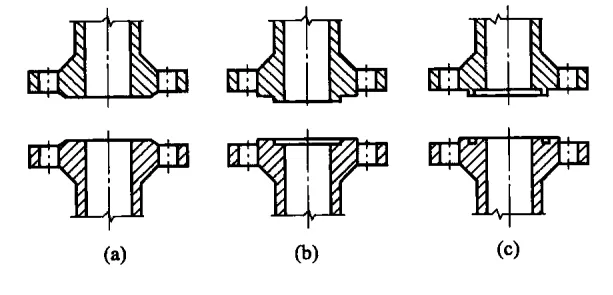

Stainless Steel Flange stiffness

Excessive warping deformation due to insufficient flange stiffness (as shown in the figure below) is often one of the main reasons for seal failure of bolted flange connection in actual production. The flange with large stiffness has small deformation, which can evenly transfer the bolt preload to the gasket, so as to improve the sealing performance of the flange.

Operating conditions

The influence of pressure, temperature and physical and chemical properties of medium on sealing performance is very complex. The influence of simple pressure and medium on sealing is not significant, but under the combined action of temperature, especially fluctuating high temperature, it will seriously affect sealing performance and even make the seal completely invalid due to fa

English

English 中 文

中 文 Español

Español Português

Português Deutsch

Deutsch Türk

Türk Pусский

Pусский عربي

عربي 한국인

한국인 日本語

日本語