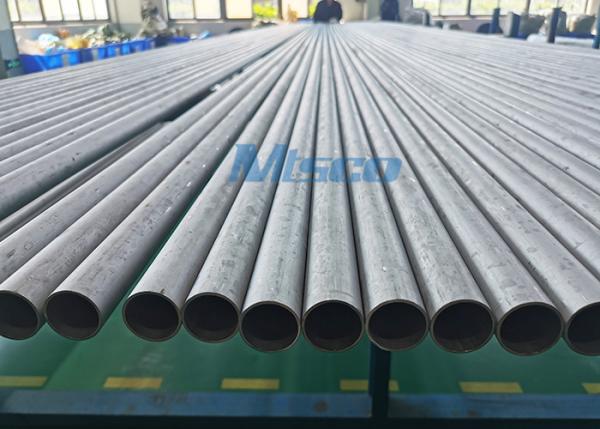

Pickled Nickel Alloy 600/601 Heat Exchanger Tube

Get Quote

Pickled Nickel Alloy Alloy 600/601 Heat Exchanger Tube For Chemical Equipment

Alloy 600 Features:

Features: Alloy 600 has good resistance to corrosion and high temperature, and has high strength and good fabricability. It resists chloride-ion-incurred stress corrosion cracking, sulfur compounds and oxidizing conditions at high temperatures.

Alloy 601 Features:

Features: Alloy 601 has good resistance to heat and corrosion, especially outstanding to oxidation at elevated temperatures up to 1200℃. It also has high strength, good fabricability and good resistance to aqueous corrosion.

Applications: Chemical process industry, heat treating fixtures, airframe components and nuclear reactors.

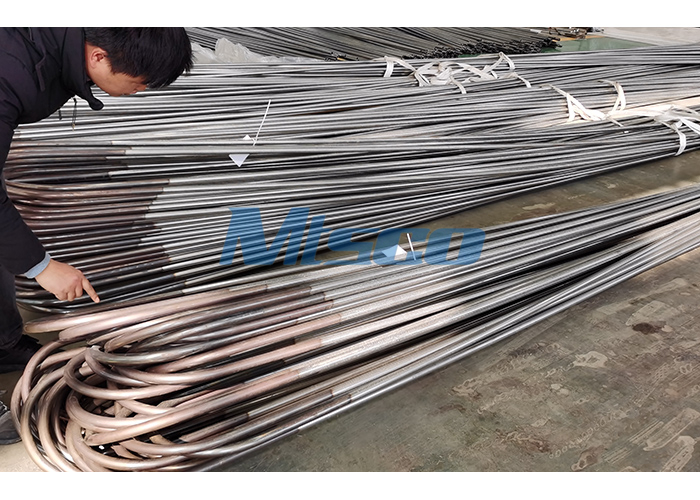

Heat Exchanger Tube Process :

1 . We use Cold Drawn technology to produce U bend tube

2 . U bend tubes produce will accordance to customer's drawings

3 . To avoid oxidation , inert gas (Argon) is passed through tubes ID at the required flow rate

4 . The radius is checked for its OD and wall thinning with the recommended specification

5 . We'll choose three different position or as customer's require to make sure tubes quality . We'll do physical properties and micro-structure test

6 . Visual inspection for waviness and cracks is done with Dye Penetrant Test

7 . Each tube is then hydro tested at the recommended pressure to check for leakage

| Grade | Alloy 600,625,800; TP304 ; TP304H ; TP304L ; TP316 ; TP316L ; TP 321 ; TP321H ; TP317L ; TP310S ; TP347H |

Standard | ASTM B516/167/751; ASTM A213 , ASTM A 269 , ASTM A789 , etc |

| Size | Routine OD : 19.05mm,25.4mm,31.8mm,38.1mm |

| WT : 1.2-2.77mm | |

Length | According to customer needs up to 20m |

| Advantage | Superior surface finish Better mechanical property More precise dimension ; Perfect inspection method and inspection equipment |

| Package | Plywood case |

Nickel Alloy Heat Exchange Tube Application :

a) Petroleum , chemical enterprise , super heater of boiler and heat exchanger

b) High temperature-resistant transmission fluid pipe in power station

c) Ship with pressure pipe

d) Exhaust purification device

e) Construction and ornament

f) solar industry , military , semiconductor etc

MTSCO heat exchanger tube with pickling and annealing surface is very popular in boilers and heat exchangers industry , water heater industry , air-conditioning industry etc . This kind of seamless tubes are have a very important position in our all products .

VIP SERVICE

VR (Virtual) Mill Introduction

Professional Remote Technical Guidanceion

Accept Third-party Inspection

Door to Door Shipment

Get QuoteRelated Products: Seamless Tube: Annealed Pickled Heat Exchanger Tube

ASTM A790 / ASME SA790 2205 / 2507 Duplex Steel Tube With Cold Rolled

Duplex stainless steel that was developed to combat common corrosion problems encountered with the 300 series stainless steels . Duplex describes a family of stainless steels that are neither fully austenitic , like 304 stainless , nor purely ferritic , like 430 stainless . The advantage of a duplex......

English

English 中 文

中 文 Español

Español Português

Português Deutsch

Deutsch Türk

Türk Pусский

Pусский عربي

عربي 한국인

한국인 日本語

日本語