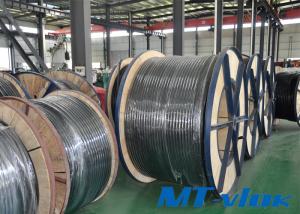

S32205 / 2205 Duplex Steel ASTM A789 3lines 1/4" Coiled Tubing Control Line

Material: TP316L, S32205, Alloy825/ N08825, Alloy400/ N04400, Alloy625/ N06625

Outer Diameter: 1/4“, 3/8”,1/2“

Wall Thickness: 0.035”,0.049“,0.065”

Length : PER FT

Application : ICV remote control,

Pressure Rating : 15000 Psi

Multi-core control line flat pack material:

| Plastic Packaging Materials | Abbreviation | Temperature℃ |

| Ethylene Tetrafluoroethylene | ETFE | -60℃~150℃ |

| Fluoronated Ethylene Propylene | FEP | -110℃~200℃ |

| High Density Polyethylene | HDPE | -60℃~100℃ |

| Perfluoroalkoxy | PFA | -80℃~260℃ |

| Modified Polypropylene | PP | 30℃~150℃ |

| Polyvinylidene Fluoride | PVDF | -30℃~150℃ |

| Thermoplastic Vulcanizating | TPV | -30℃~150℃ |

| Nylon11 | PA11 | -30℃~150℃ |

Where the coiled tubing used ?

1 . Control tubing in oil and gas well

2 . Instrument tubing

3 . Chemicl injection tubing line

4 . Pre-insulated tubing

5 . Electric heating or steam heating tubing line

6 . Hater tubing line

Duplex Steel Tube Test :

1 . NTD ( Ultrasonic test , Eddy Current test )

2 . Mechanical Test ( Tension Test , Flaring Test , Flattening Test , Hardness Test , Hydraulic test )

3 . Metal Test ( Metallographic Analysis , Impact Test-High/low temperature )

4 . Chemical Analysis ( Photoelectric Emission Spectroscopic )

MTSCO has been supplying industrial tubing to the oil and gas industry for more than a decade. In recent years, we have continued to make breakthroughs in the field of coiled tubing, downhole control lines, and chemical injection control lines. Our coiled tubing has been successfully used in certain harsh subsea and downhole conditions, and through continuous research and development, is able to meet the stringent quality requirements of the oil and gas industry and other industries.

VIP SERVICE

VR (Virtual) Mill Introduction

Professional Remote Technical Guidanceion

Accept Third-party Inspection

Door to Door Shipment

Get QuoteRelated Products: Coiled Tubing, Control Line: Encapsulated Tube

ASTM A213 304 / 304L 1.4301 / 1.4306 Stainless Steel Welded Multi-core Coiled Tube

Where the multi-core coiled tubing used ? Mtsco' s multi-core tubes are used for pneumatic and hydraulic remote control, measuring and monitoring systems. materials are ASTM TP316/ 316L, TP304/304L. The multi-core tube consists of one to nine stainless steel tubes laid up spirally inside an ex......

ASTM A213 S30400 / S30403 Stainelss Steel Multi-core Coiled Tubing

The multi-core tube consists of one to nine stainless steel tubes laid up spirally inside an extruded outer PVC sheath. For easy identification and protection purposes each individual tube is PVC sheathed in a different color. The extruded outer sheath is made of oil and seawater resistant, weatherp......

S31603 / S30403 Stainless Steel Small Diameter Welded Marine Multi-core Coiled Tubing

Mtsco' s multi-core tubes are used for pneumatic and hydraulic remote control, measuring and monitoring systems. materials are ASTM TP316/ 316L, TP304/304L. The multi-core tube consists of one to nine stainless steel tubes laid up spirally inside an extruded outer PVC sheath. For easy identification......

English

English 中 文

中 文 Español

Español Português

Português Deutsch

Deutsch Türk

Türk Pусский

Pусский عربي

عربي 한국인

한국인 日本語

日本語