The production process of stainless steel seamless pipe&tube with video

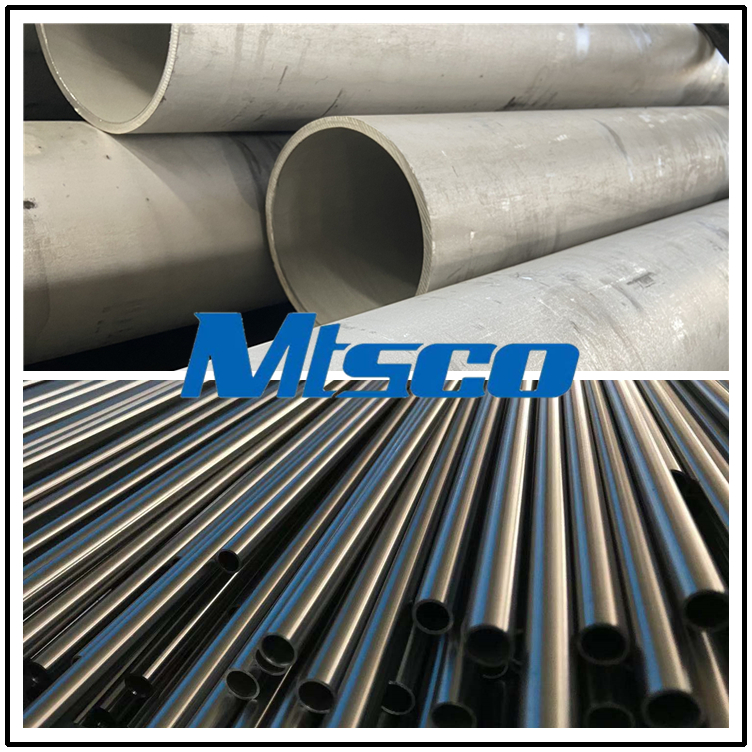

Although the terms pipe and tube are often used interchangeably, in most cases, in terms of function, we generally default to PIPE for large tubes and TUBE for small tubes, pipes being used for transport, such as oil and gas control lines, and tubes being used for other applications such as heat exchange.

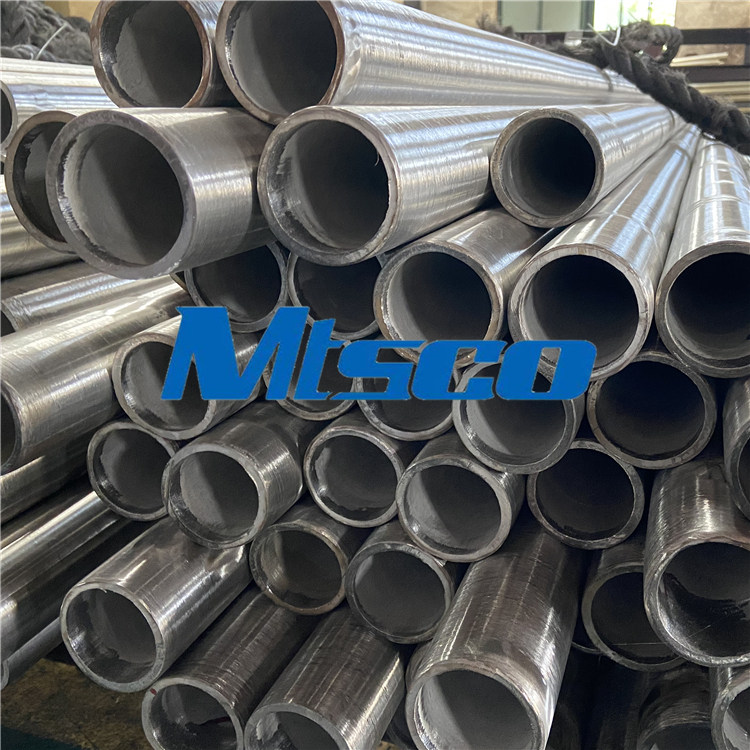

Seamless steel pipes/tubes manufacturing

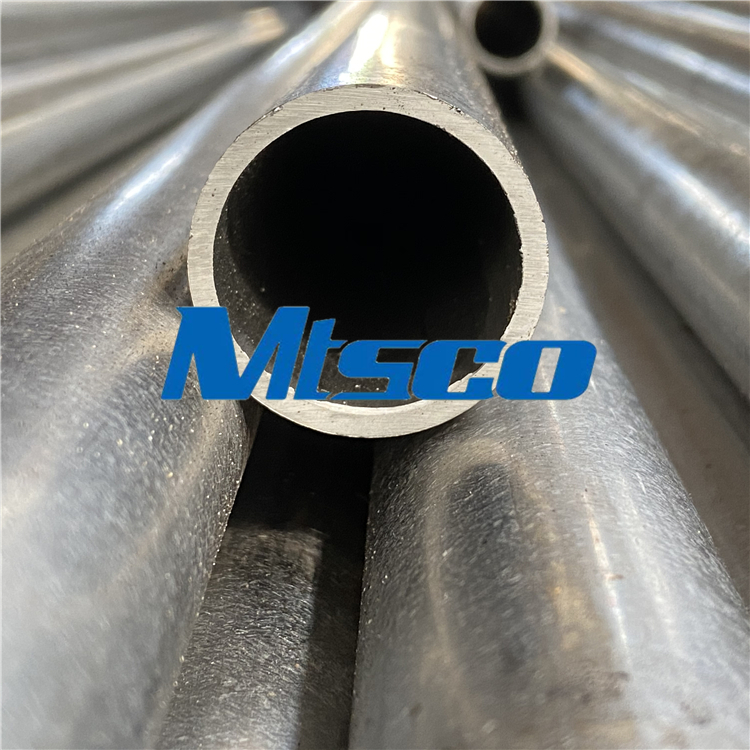

Seamless pipe/tube is defined as - they do not have welded seams. Seamless pipes/tubes are manufactured through an extrusion process where the tube is extruded from solid round steel into a hollow shape and then formed into a qualified seamless tube through multiple processes such as piece, pickling, heat treatment, cold rolling or cold drawing, and inspection.

As we can see from the manufacturing process of seamless pipes/tubes, seamless pipes/tubes are completely homogeneous tubes with characteristics that make them stronger, more resistant to corrosion, and able to withstand higher pressures. This makes them more suitable for critical applications in harsh environments and, of course, relatively more expensive for seamless tubes.

MT produces seamless tubes in stainless steel:

Austenitic: 304/304L, 316/316L, 347/347H, 321/321H, 904L, etc.

Ferritic: 405, 409, 410, 430, 444, 446, etc.

Duplex: S31803, S32750, S32760, etc.

Nickel alloy material:

Alloy:600,601,625,800,825,C276 etc.

Through this video, you can clearly see how our seamless tubes are produced

www.youtube.com/watch?v=LyItpC6zDaE

English

English 中 文

中 文 Español

Español Português

Português Deutsch

Deutsch Türk

Türk Pусский

Pусский عربي

عربي 한국인

한국인 日本語

日本語