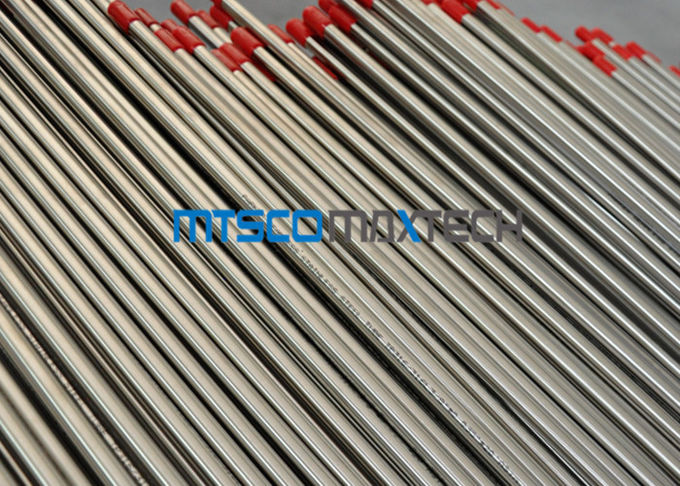

TP304/304L Stainless Steel Instrumentation Tubing, Bright Annealed Pipe

SSBA44

Price: From $6000-9900USD/TON

Material: 304, 1.4301, X5CrNi18-10; 304H, S30415, 1.4948, S30409; 304L, 1.4306, S30403, 1.4307;

Get Quote

Stainless Steel Instrumentation Tubing

Stainless steel instrument tubing can be used as a connecting tube between the instrument and the fluid or other equipment to improve the detection efficiency.

Stainless steel instrumentation tube is a kind of industrial piping product widely used in petroleum, chemical, electric power, paper making and other industries for connecting meters, instruments, sensors, valves and other equipment. This kind of product has a unique role in measuring and controlling fluid parameters, such as pressure, temperature, flow and liquid level. Its application mainly involves the following aspects:

Instrumentation: Instrumentation is a device used to measure and control fluid parameters, by ensuring accurate and stable fluid transmission, the performance and reliability of the instrument can be improved. Stainless steel instrument tube can be used as a connection tube between the instrument and the fluid or other equipment to ensure the quality of fluid transmission.

Instrumentation: Instrumentation is the equipment used to analyze and detect the characteristics of the composition, nature and state of the fluid, etc. By preventing the contamination and loss of the fluid, the accuracy and sensitivity of the instrumentation can be improved. Stainless steel instrument tubing can be used as a connecting tube between the instrument and the fluid or other equipment to improve the detection efficiency and reliability of the instrument.

Sensor: Sensor is a device used to sense and convert the physical or chemical quantity of fluid into electrical signal, through the continuous and stable monitoring of the fluid, it can improve the control ability of the fluid. Stainless steel instrumentation tubing can be used as a connecting tube between the sensor and the fluid or other equipment, which improves the response speed and signal quality of the sensor by maintaining the stability and continuity of the fluid.

Valve: Valve is a kind of equipment used to regulate and cut off the state of fluid flow direction, speed and pressure, etc. By regulating the regulation and control ability of the fluid, the regulation and control effect of the fluid can be improved. Stainless steel instrument tube can be used as a connecting tube between the valve and the fluid or other equipment, which improves the sealing and durability of the valve by withstanding a large internal and external pressure difference and preventing leakage.

TP304 / 304L Stainless Steel Seamless Tube For Instrument With Bright Annealed Surface

MTSCO instrument products are made with high quality raw material. Advanced manufacture equipments and the exquisite craft, technology, characteristic of high precise size, good quality surface, stable performace, especially for the reliable durable performance under high temperature. It is widely applied in heat exchanger and condenser tubes, gas spring and lifter tubes, shock absorber tubes, automobile motocycle tubes, hydraulic tube.High pressure and super critical pressure steam boiler and so on.

Material Grade :

| American Standard | TP304 , TP304L , TP310S , TP316 , TP316L , TP316Ti , TP321 , TP347 , 904L , S31803 Etc |

| European Standard | 1.4301 , 1.4306 , 1.4845 , 1.4401 , 1.4404 , 1.4571 , 1.4541 , 1.4550 , 1.4539 , 1.4462 Etc |

| German Standard | X5CrNi18-10 , X2CrNi19-11 , X12CrNi25-21 , X5CrNi17-12-2 , X5CrNi17-12-3 , X2CrNiMo18-14-3 , X6CrNiTi18-10 , X6CrNiTb18-10 Etc |

Applications :

1 . General service industries ( petroleum , food , chemical , paper , fertilizer , fabric , aviation and nuclear )

2 . Fluid , gas and oil transport

3 . Pressure and heat transmission

4 . Construction and ornament

5 . Boiler and heat exchangers

6 . Decorative usage ( road lamp facilities , bridge handrail , expressway railing , bus stop , airport and gymnasium ) Etc

| Advantages | a) Superior surface finish |

| b) Better mechanical property | |

| c) More precise dimension | |

| d) Perfect inspection method and inspection equipment | |

| Price Item | FOB , CFR , CIF or as negotiation |

| Payment | T/T, LC or as negotiation |

| Delivery Time | 30 working days after received your deposit ( Normally according to the order quantity ) |

| Package | Iron case ; woven bag or as per customer’s requirement |

| Quality Requirement | Mill Test Certificate will be supplied with shipment , Third Part Inspection is acceptable |

| Test | NTD ( Ultrasonic test , Eddy Current test ) |

| Mechanical Test ( Tension Test , Flaring Test , Flattening Test , Hardness Test , Hydraulic test ) | |

| Metal Test ( Metallographic Analysis , Impact Test - High / low temperature ) | |

| Chemical Analysis ( Photoelectric Emission Spectroscopic ) |

ASTM A213 / A213M Chemical Composition :

| Elements | 304L(wt%) S30403 | 304(wt%) S30400 | 316L (wt%) S31603 | 316 (wt%) S31600 |

| (C) Carbon, max | 0.035 | 0.08 | 0.035 | 0.08 |

| (Mn) Manganese, max | 2 | 2 | 2 | 2 |

| (P) Phosphorus, max | 0.045 | 0.045 | 0.045 | 0.045 |

| (S) Sulfur, max | 0.03 | 0.03 | 0.03 | 0.03 |

| (Si) Silicon, max | 1 | 1 | 1 | 1 |

| (Ni) Nickel | 8.0 - 12.0 | 8.0 - 11.0 | 10.0 - 14.0 | 10.0 - 14.0 |

| (Cr) Chromium | 18.0 - 20.0 | 18.0 - 20.0 | 16.0 - 18.0 | 16.0 - 18.0 |

| (Mo) Molybdenum | N/A | N/A | 2.0 - 3.0 | 2.0 - 3.0 |

| (Fe) Iron | Bal. | Bal. | Bal. | Bal. |

| (Cu) Copper | N/A | N/A | N/A | N/A |

| (N) Nitrogen | N/A | N/A | N/A | N/A |

VIP SERVICE

VR (Virtual) Mill Introduction

Professional Remote Technical Guidanceion

Accept Third-party Inspection

Door to Door Shipment

Get QuoteRelated Products: Seamless Tube: Bright Annealed Polished Tube

Alloy C22 / UNS N06022 Nickel Alloy C22 Seamless Heat Exchanger Tube

MTSCO is a leading manufacturer who is specialized in stainless steel seamless pipes , bright annealed tubes , seamless coiled tubing etc basic products . We also have duplex stainless steel tubes and pipes , nickel alloy tubes and pipes etc . MTSCO has the most advanced producing and testing equipm......

ASTM A213/ASTM A269 Bright Annealing Stainless Steel 316L Capillary Tube

MTSCO has been dedicated to producing bright annealed tubes since 2014 , owning complete producing technology and abundant managing experience . And the raw material of stainless steel seamless tube such as mother tube , round bar we use is from Chinese biggest and well-known steel mill : Walsin , Y......

Alloy C276/UNS N10276 Nickel Alloy Seamless Pipe/Tube, ASTM B619 / ASME SB619

1. Material Grade: UNS N10276, UNS N10001, UNS N10665, UNS N10675, UNS N06022, N08800, N08825, N04400; etc 2. Outer Diameter: 3.18mm-101.6mm Wall Thickness: 0.5mm-20mm 3. Length: Normally fixed length 6m, can as per customer’s requirement 4. Standard: ASTM B169; ASTM B167; ASTM B444; ASTM ......

English

English 中 文

中 文 Español

Español Português

Português Deutsch

Deutsch Türk

Türk Pусский

Pусский عربي

عربي 한국인

한국인 日本語

日本語