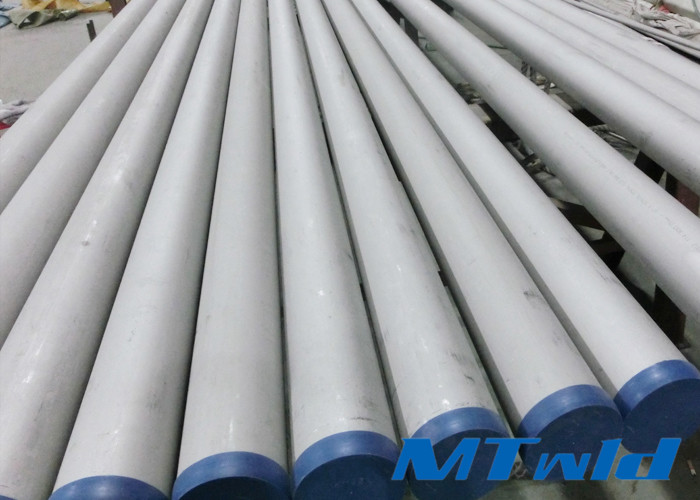

TP304, TP304L, TP316, TP316L ERW/EFW Stainless Welded Pipe

SSAPWP11

Material: 304, 1.4301, X5CrNi18-10; 304H, S30415, 1.4948, S30409; 304L, 1.4306, S30403, 1.4307; 316L, 1.4401, 1.4404, 1.4435;

Get Quote

TP304 , TP304L , TP316 , TP316L Stainless Welded Pipe , ERW / EFW

Standards :

ASTM A269 - 10 : Standard Specification for Seamless and Welded Austenitic Stainless Steel Tubing for General Service

ASTM A312 / A312M - 12 : Standard Specification for Seamless , Welded , and Heavily Cold Worked Austenitic Stainless Steel Pipes

ASTM A789 / A789M - 10a : Standard Specification for Seamless and Welded Ferritic / Austenitic Stainless Steel Tubing for General Service

ASTM A790 / A790M - 11 : Standard Specification for Seamless and Welded Ferritic / Austenitic Stainless Steel Pipe

| Industry & Advantage | Application | a) For fluid & gas transport |

| b) Structure & machining etc | ||

| Advantages | a) Advanced technology of cold draw machine | |

| b) Advanced annealing machine | ||

| c) Better mechanical property | ||

| d) More precise dimension | ||

e) Perfect inspection method and inspection equipment etc |

Test :

1 . X-ray , Size test , Length test

2 . Chemical Analysis ( Photoelectric Emission Spectroscopic ) etc

MTSCO has been dedicated to producing welded pipe and tube since 2003 , owning complete producing technology and abundant managing experience . And we have ISO 9001 and PED certificate , and the Third Party Inspection Certificates such as TUV , BV , Lloyd’s , SGS , etc , also can be provided according to customers' requirements .

MTSCO is a leading manufacturer who is specialized in stainless steel seamless pipes , bright annealed tubes , seamless coiled tubing etc . In order to facilitate customers, we have welded pipes and tubes too. MTSCO has the most advanced producing and testing equipment . We can totally satisfy your requirement . According to standard very strictly , pipes which produced by us always have correct OD and WT tolerance .

| Price Item : | FOB, CFR, CIF or as negotiation |

| Payment : | T/T, LC or as negotiation |

| Delivery Time : | 30 working days after received your deposit (Normally according to the order quantity) |

| Package : | Iron case; woven bag or as per customer’s requirement |

| Quality Requirement : | Mill Test Certificate will be supplied with shipment, Third Part Inspection is acceptable |

ASTM A269 Chemical Composition :

| Elements | 304L(wt%) S30403 | 304(wt%) S30400 | 316L (wt%) S31603 | 316 (wt%) S31600 |

| (C) Carbon, max | 0.035 | 0.08 | 0.035 | 0.08 |

| (Mn) Manganese, max | 2 | 2 | 2 | 2 |

| (P) Phosphorus, max | 0.045 | 0.045 | 0.045 | 0.045 |

| (S) Sulfur, max | 0.03 | 0.03 | 0.03 | 0.03 |

| (Si) Silicon, max | 1 | 1 | 1 | 1 |

| (Ni) Nickel | 8.0 - 12.0 | 8.0 - 11.0 | 10.0 - 14.0 | 10.0 - 14.0 |

| (Cr) Chromium | 18.0 - 20.0 | 18.0 - 20.0 | 16.0 - 18.0 | 16.0 - 18.0 |

| (Mo) Molybdenum | N/A | N/A | 2.0 - 3.0 | 2.0 - 3.0 |

| (Fe) Iron | Bal. | Bal. | Bal. | Bal. |

| (Cu) Copper | N/A | N/A | N/A | N/A |

| (N) Nitrogen | N/A | N/A | N/A | N/A |

VIP SERVICE

VR (Virtual) Mill Introduction

Professional Remote Technical Guidanceion

Accept Third-party Inspection

Door to Door Shipment

Get QuoteRelated Products: Welded Pipe: Stainless Steel Welded Pipe

ASTM A358 / ASME SA358 TP321 / 321H Annealed & Pickled Stainless Steel Double Weled Pipe

1. Material Grade: TP304 , TP304L , TP304H , TP316 , TP316L , TP316Ti , TP309S , TP310S , TP321 , TP321H , TP347 , TP347H , etc 2. Outer Diameter: 10.3mm-1219mm Wall Thickness : 1.24mm-59.54mm 3. Length: Normally fixed length 6m , can as per customer's requirement 4. Standard: ASTM A312 ; AS......

ASTM A358 TP316L Welded Stainless Steel Industrial Pipe

Material Grade: TP304 , TP304L , TP304H , TP316 , TP316L , TP316Ti , TP309S , TP310S , TP321 , TP321H , TP347 , TP347H , etc Outer Diameter:5.80mm - 2032mm ( 0.23 to 80 ) Wall Thickness: 0.25mm - 28mm ( 0.01 to 1.125 ) Length: Normally fixed length 6m , can as per customer’s requirement Standar......

ASTM A312 Stainless Steel Welded Pipe 1.4301 / 1.4404 / 1.4306 / 1.4401

Material Grade : American Standard TP304 , TP304L , TP310S , TP316 , TP316L , TP316Ti , TP321 , TP347 , 904L , S31803 Etc European Standard 1.4301 , 1.4306 , 1.4845 , 1.4401 , 1.4404 , 1.4571 , 1.4541 , 1.4550 , 1.4539 , 1.4462 Etc German Standard X5CrNi18-10 , X2CrNi19-11 , X12CrNi25-21 , X5Cr......

English

English 中 文

中 文 Español

Español Português

Português Deutsch

Deutsch Türk

Türk Pусский

Pусский عربي

عربي 한국인

한국인 日本語

日本語