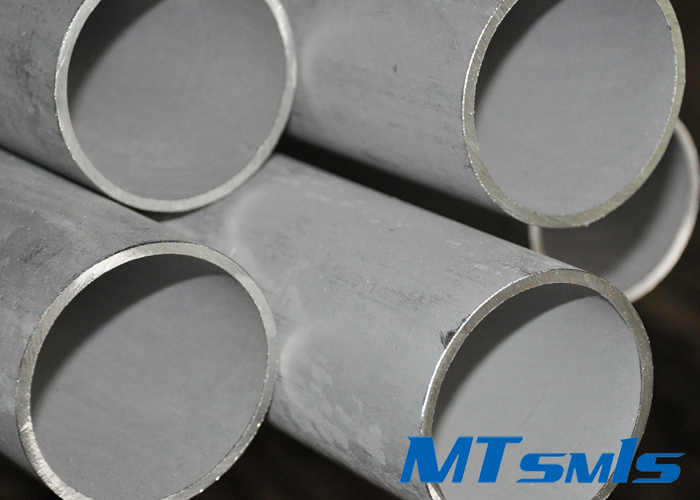

TP316/316L 1.4401 Austenitic Stainless Steel Seamless Pipe

MTASSP02

Price: From $3900-4900USD/TON

Material: 304L, 1.4306, S30403, 1.4307; 316L, 1.4401, 1.4404, 1.4435; 316Ti, S31615, 1.4571, S31635;

Get Quote

TP316 / 316L 1.4401 / 1.4435 Austenitic Stainless Steel Pipe With Annealed & Pickled Surface

Specifications of Austenitic Stainless Steel Pipe

| Grade | Standard | Outside Diameter | 8mm-711mm |

| TP304 TP304L TP316 TP316L TP317L TP321 TP321H TP347 TP347H TP904L | ASTM-A312 ASTM-A790 ASTM-B167/163 ASTM-B444 ASTM-B622 ASTM-B423 EN10216 GOST ...... | Wall Thickness | 1mm-50mm |

| Length | ≤20m | ||

| Inspection | Appearance/ Dimensional test, PMI; NDT: UT/ ET/ HT; Physical & chemical test | ||

| Certificates | ISO/PED/AD2000/TS | ||

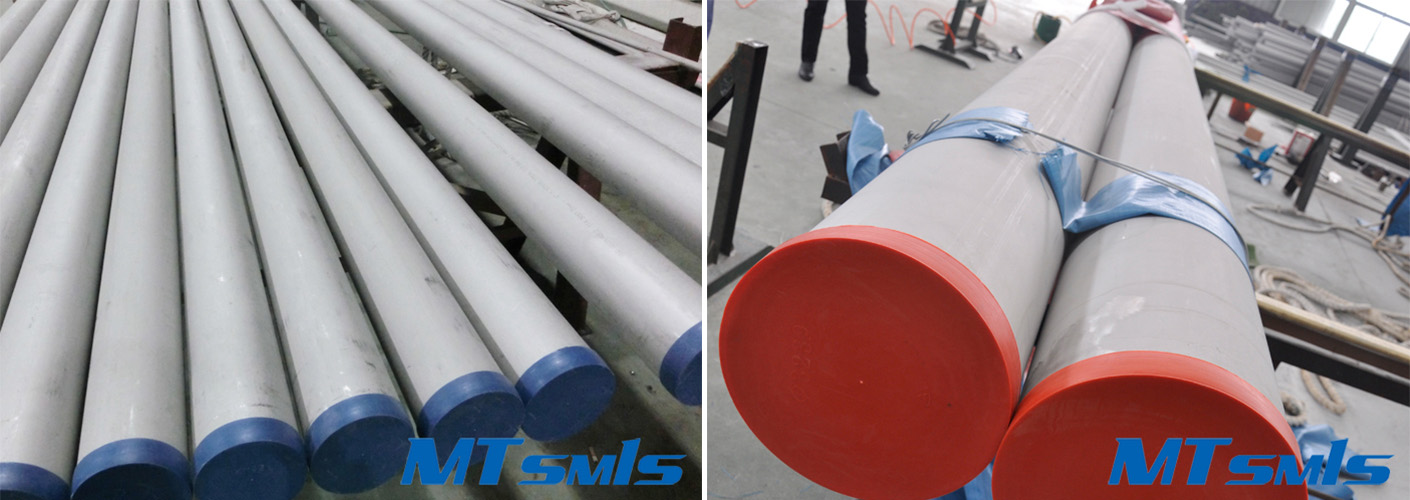

| Package | End protection/ Woven bags/ Wooden cases |

Why Choose MTSCO Austenitic Stainless Steel Pipe?

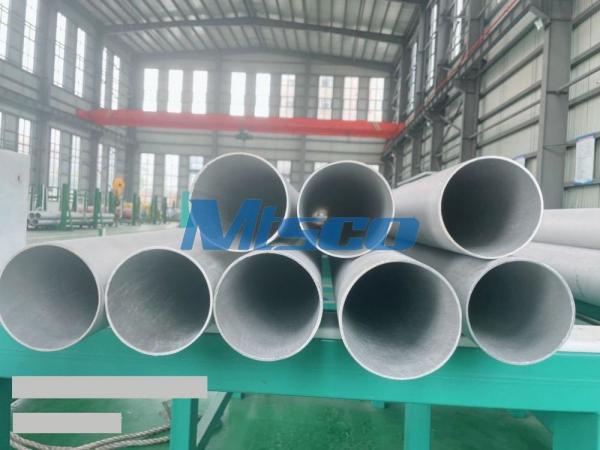

1. Highly reliable seamless pipe manufacturer -MTSCO invested in a factory with 35 years of experience in Austenitic Stainless Steel pipe making, Huxin Pipe

Applications of TP316 Austenitic Stainless Steel Pipe

Heat Exchangers and Piping Systems: Widely used in heat exchangers, boilers, and piping systems due to its high-temperature resistance and durability.

Chemical Composition of Austenitic Stainless Steel

| Material | Chemical Composition % Max | ||||||||||

| C | Mn | P | S | Si | Cr | Ni | Mo | N B | Nb | Ti | |

| TP304 | 0.08 | 2 | 0.045 | 0.03 | 1 | 18.0-20.0 | 8.0-11.0 | - | - | - | - |

| TP304L | 0.035 | 2 | 0.045 | 0.03 | 1 | 18.0-20.0 | 8.0-12.0 | - | - | - | - |

| TP316 | 0.08 | 2 | 0.045 | 0.03 | 1 | 16.0-18.0 | 10.0-14.0 | 2.00-3.00 | - | - | - |

| TP316L | 0.035 | 2 | 0.045 | 0.03 | 1 | 16.0-18.0 | 10.0-15.0 | 2.00-3.00 | - | - | - |

| TP321 | 0.08 | 2 | 0.045 | 0.03 | 1 | 17.0-19.0 | 9.0-12.0 | - | - | - | 5C -0.70 |

| TP347 | 0.08 | 2 | 0.045 | 0.03 | 1 | 17.0-19.0 | 9.0-12.0 | - | - | 10C -1.10 | - |

Quality Control of MTSCO Austenitic Stainless Steel Seamless Pipe

Quality Control of Raw Materials

MTSCO sources pipe raw materials from large steel mills like Baosteel and Tsingshan. Each raw material batch undergoes warranty and PMI checks to ensure quality. PMI and other inspections are conducted to verify compliance with material requirements.

Process Control During Production

MTSCO's Austenitic Stainless Steel seamless pipe production involves cold rolling, cold drawing, annealing, pickling, and surface treatment. Advanced production equipment and experienced engineers supervise every process step, documenting each for archiving. Process cards guarantee accuracy and traceability throughout production.

Quality Control Before Shipment

MTSCO boasts a professional QC team conducting various inspections and experiments on products: appearance, PMI, size, quantity, and more. Mechanical, hardness, ultrasonic, eddy current, and hydraulic tests are performed. Additionally, third-party tests (SGS, TUV, BV) are accepted. Prior to shipping, we ensure secure packaging and reinforce containers to prevent transportation damage.

What is the advantage of stainless steel?

Classification and properties of stainless steel

Ferritic stainless steel is a common type of stainless steel material, is a kind of ferrite organization in the state of use mainly stainless steel. The chromium content of this type of stainless steel is between 11% and 30%, in addition, it also contains small amounts of molybdenum, titanium, niobium and other elements.

Advantages: corrosion resistance, good oxidation resistance, excellent stress resistance, good thermal conductivity, small coefficient of expansion

Austenitic stainless steel is a kind of stainless steel material with stable austenitic organization, which contains 18% of chromium and about 8% of nickel, but also contains a small amount of molybdenum, titanium, nitrogen and other elements.

Advantages: good overall performance, can be resistant to corrosion of a variety of media, toughness and plasticity are relatively good, easy to cut strong performance

Austenitic - ferritic duplex stainless steel is a kind of internal austenite and ferrite organization structure of each half of the stainless steel products.

Characteristics: with the austenitic stainless steel materials and ferritic stainless steel materials, and compared with the ferritic stainless steel, its plasticity is better, higher toughness, compared with the austenitic stainless steel, its thermal conductivity is better, the expansion coefficient is smaller.

VIP SERVICE

VR (Virtual) Mill Introduction

Professional Remote Technical Guidanceion

Accept Third-party Inspection

Door to Door Shipment

Get QuoteRelated Products: Seamless Pipe: Stainless Steel Seamless Pipe

18Inch Stainless Steel Seamless Pipe With Pickled Surface

MTSCO has been dedicated to producing seamless stainless steel pipe since 2003 , owning complete producing technology and abundant managing experience . Our raw material such as mother tube , round bar we use is from Chinese biggest and well known steel mill : Walsin , Yongxing etc . And We have adv......

ASTM A312 TP304 / 304L Stainless Steel Annealed & Pickled Seamless Industrial Pipe

Grade: TP 304; TP304H; TP304L; TP316; TP316L; TP 321;TP321H; TP317L; TP310S; TP347H Standard:ASTM A213, ASTM A 269, ASTM A 270,EN10216-5; ASTM B 622;ASTM B516;ASTM A789, etc Size OD:10.3-1219mm WT:1.24-59.54mm Length:Max.12M Advantage:Superior surface finish ,better mechanical property......

12 Inch Sch40 TP347 / 347H Austenitic Stainless Steel Pipe With Annealed & Pickled Surface

MTSCO is a leading manufacturer who is specialized in seamless stainless steel pipes , bright annealed tubes , seamless coiled tubing etc . MTSCO has the most advanced producing and testing equipment . We can totally satisfy your requirement . Seamless stainless steel pipes final surface are p......

English

English 中 文

中 文 Español

Español Português

Português Deutsch

Deutsch Türk

Türk Pусский

Pусский عربي

عربي 한국인

한국인 日本語

日本語