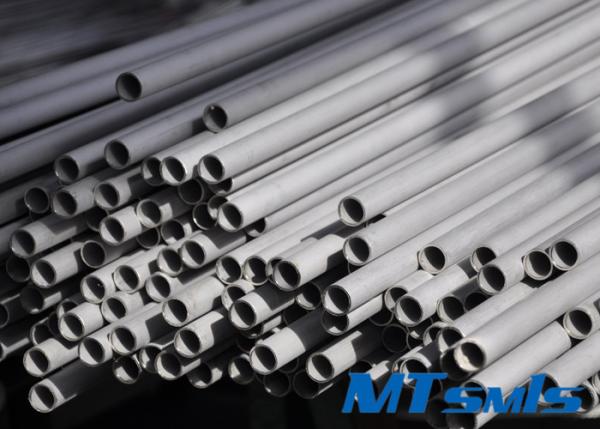

TP316L / 1.4404 Stainless Steel Heat Exchanger Tube , U Tube With Pickling Surface

Material: 316L, 1.4401, 1.4404, 1.4435;

Get Quote

TP316L / 1.4404 Stainless Steel Heat Exchanger Tube , U Tube With Pickling Surface、

Item | Description |

Material Grade | TP304 / 304L ; TP316 / 316L ; TP321 / 321H ; TP317L ; TP310S ; TP347H etc |

Outer Diameter | Routine OD : 19.05mm,25.4mm,31.8mm,38.1mm,etc. |

Wall Thickness | 1.2-2.77mm |

Length | According to customer’s requirement |

Standard | ASTM A213 ; ASTM A269 ;etc . |

Process Method | Cold Rolled / Cold Drawn |

Application | a) Petroleum , chemical enterprise , super heater of boiler and heat exchanger |

b) High temperature-resistant transmission fluid pipe in power station | |

c) Ship with pressure pipe | |

e) Construction and ornament | |

f) solar industry , military , semiconductor etc | |

Advantages | a) Advanced technology of cold draw machine |

b) Advanced annealing machine | |

c) Better mechanical property and more precise dimension | |

d) Perfect inspection method and inspection equipment etc | |

Price Item | FOB , CFR , CIF or as negotiation |

Payment | T / T , LC or as negotiation |

Delivery Time | 30 working days after received your deposit ( Normally according to the order quantity ) |

Package | Iron case ; plywood case , woven bag or as per customer’s requirement |

Quality Requirement | Mill Test Certificate will be supplied with shipment , Third Part Inspection is acceptable |

Test | NTD ( Ultrasonic test , Eddy Current test ) |

Mechanical Test ( Tension Test , Flaring Test , Flattening Test , Hardness Test , Hydraulic test ) | |

Metal Test ( Metallographic Analysis , Impact Test-High / low temperature ) | |

Chemical Analysis ( Photoelectric Emission Spectroscopic ) | |

Main Market | Europe , Middle East , Southeast Asia , South America . etc |

Process :

1 . We use Cold Drawn techonology to produce U bend tube

2 . U bend tubes produce will accordance to customer's drawings

3 . To avoid oxidation , inert gas (Argon) is passed through tubes ID at the required flow rate

4 . The radius is checked for its OD and wall thinning with the recommended specification

5 . We'll choose three different position or as customer's require to make sure tubes quality . We'll do physical properties and micro-structure test

6 . Visual inspection for waviness and cracks is done with Dye Penetrant Test

7 . Each tube is then hydro tested at the recommended pressure to check for leakage

VIP SERVICE

VR (Virtual) Mill Introduction

Professional Remote Technical Guidanceion

Accept Third-party Inspection

Door to Door Shipment

Get QuoteRelated Products: Seamless Tube: Annealed Pickled Heat Exchanger Tube

2205 Material Duplex Steel Tube Hydraulic Test With Pickling Surface

S32205 duplex stainless steel tube combines excellent corrosion resistance and high strength, and can effectively resist pitting, crevice corrosion and stress corrosion cracking caused by chloride ions....

English

English 中 文

中 文 Español

Español Português

Português Deutsch

Deutsch Türk

Türk Pусский

Pусский عربي

عربي 한국인

한국인 日本語

日本語