Where are superalloys used?

Superalloy (also known as heat-resistant alloy) is a metal material with long-time creep resistance, high endurance strength and high corrosion resistance under the simultaneous action of stress and high temperature (above 600 ℃). With excellent oxidation resistance and thermal corrosion resistance, superalloys are widely used in aviation engines, automobile engines, gas turbines, nuclear power, petrochemical and other fields.

1. Aerospace

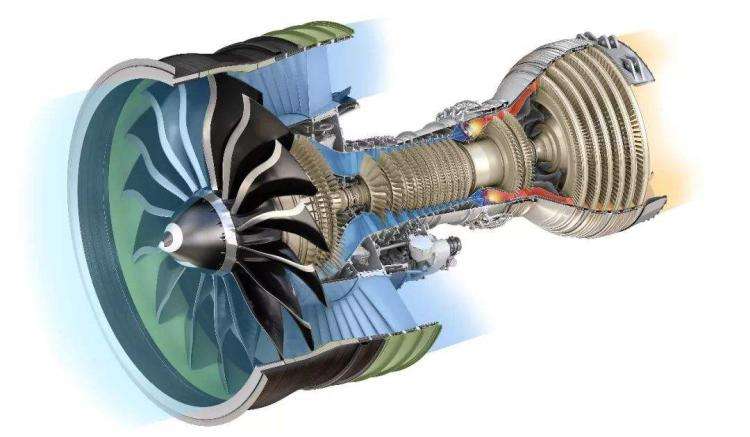

Superalloys have been used in aeroengines since their birth. In modern aeroengines, superalloys are mainly used in four hot end components: combustion chamber, guide vane, turbine disk and turbine blade.

For example, the combustion chamber is dominated by nickel base or cobalt base superalloys, such as Haynes 188 and Hastelloy X

2. Nuclear power

Superalloys for nuclear power include fuel element cladding materials, structural materials, fuel rod positioning grid, high-temperature gas furnace heat exchanger, etc. Inconel 690 and Incoloy 800 are mainly used as heat transfer tubes of PWR steam generator

3. Petrochemical Industry

In oil and gas exploitation, especially in deep well exploitation, the drilling tools are in an acidic environment of 4 ~ 150 ℃, coupled with the existence of carbon dioxide, sulfur dioxide and sediment, corrosion-resistant and wear-resistant superalloys must be used.

Various valves on Inconel 718 oil and gas production drilling tools

·Incoloy 825 rope pipeline, water pressure control pipeline, etc

·Inconel 625 water pressure standby pipeline

·Inconel 600 safety bulkhead

4. Gas turbine

Gas turbine is another main application of superalloy. Its structure and principle are similar to that of aeroengine. Since the temperature of the gas injected into the impeller by the gas turbine is as high as 1300 ℃, the impeller needs to be made of superalloy.![]()

English

English 中 文

中 文 Español

Español Português

Português Deutsch

Deutsch Türk

Türk Pусский

Pусский عربي

عربي 한국인

한국인 日本語

日本語