Why can Stainless Steel Resist Corrosion?

The corrosion resistance of stainless steel is mainly due to the addition of a high content of Cr element in the steel. Cr element is easy to oxidize and can quickly form a dense Cr2O3 oxide film on the surface of the steel. The corrosion resistance of stainless steel mainly depends on the very thin (about 1nm) dense passive film covered on the surface. This passive film is isolated from the corrosive medium and is the basic barrier for stainless steel protection, If the passive film is incomplete or defective, the stainless steel will still be corroded.

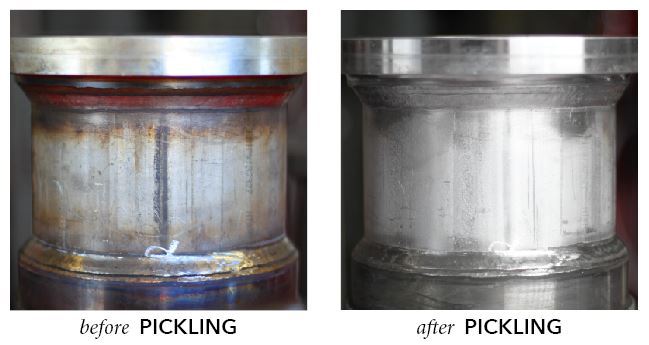

Stainless steel placed in the air will form an oxide film, but the protection of this film is not perfect. The average thickness of the stainless steel surface is 10 mm through pickling μ The surface of one layer of M is corroded, and the chemical activity of the acid solution makes the dissolution rate of the defective part higher than that of other parts on the surface. Therefore, pickling can make the whole surface tend to be uniform and balanced. More importantly, through pickling and passivation, iron and iron oxides are dissolved prior to chromium and chromium oxides, and the chromium poor layer is removed to enrich chromium on the surface of stainless steel, Under the action of oxidant passivation, a complete and stable passivation film is produced on the surface. The potential of this chromium rich passivation film can reach + 1.0V (SCE), which is close to the potential of precious metals, and the stability of corrosion resistance is improved.

According to different operation modes, stainless steel pickling and passivation treatment mainly includes six methods: immersion method, paste method, brushing method, spray method, circulation method and electrochemical method,

English

English 中 文

中 文 Español

Español Português

Português Deutsch

Deutsch Türk

Türk Pусский

Pусский عربي

عربي 한국인

한국인 日本語

日本語