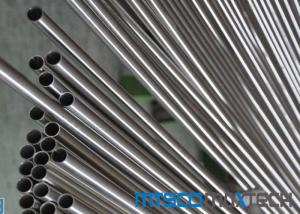

1 / 2 Inch Sch80s ASTM A269 Bright Annealed Stainless Steel Sanitary Tube

SSBA19

Price: From $6000-12000USD/TON

Material: 304, 1.4301, X5CrNi18-10; 304L, 1.4306, S30403, 1.4307; 316L, 1.4401, 1.4404, 1.4435; 309/309S/309H, 1.4833; 310/310S/310H,1.4845;

Get Quote

1 / 2 Inch Sch80s ASTM A269 Bright Annealed Stainless Steel Sanitary Tube

Bright annealed sanitary tube has very clean inner surface . MTSCO has our own high technology , when tubes have been produced they already have cleaned inner surface , even though we haven’t cleaned them . Of cause , we’ll do clean later . So when we finished clean process , the tubes are totally clean enough !

MTSCO tubes can be used in General service industries ( petroleum , food , chemical , paper , fertilizer , fabric , aviation and nuclear ) , fuild & gas & oil transport industries , pressure and heat transmission industries , construction and ornament industries , boiler and heat exchangers industries , decorative usage ( road lamp facilities , bridge handrail , expressway railing , bus stop , airport and gymnasium ) etc .

| Material | ASTM A269 Chemical Composition % Max | ||||||||||

| C | Mn | P | S | Si | Cr | Ni | Mo | N B | Nb | Ti | |

| TP304 | 0.08 | 2 | 0.045 | 0.03 | 1 | 18.0-20.0 | 8.0-11.0 | ^ | ^ | ^ . | ^ |

| TP304L | 0.035 | 2 | 0.045 | 0.03 | 1 | 18.0-20.0 | 8.0-12.0 | ^ | ^ | ^ | ^ |

| TP316 | 0.08 | 2 | 0.045 | 0.03 | 1 | 16.0-18.0 | 10.0-14.0 | 2.00-3.00 | ^ | ^ | ^ |

| TP316L | 0.035 D | 2 | 0.045 | 0.03 | 1 | 16.0-18.0 | 10.0-15.0 | 2.00-3.00 | ^ | ^ | ^ |

| TP321 | 0.08 | 2 | 0.045 | 0.03 | 1 | 17.0-19.0 | 9.0-12.0 | ^ | ^ | ^ | 5C -0.70 |

| TP347 | 0.08 | 2 | 0.045 | 0.03 | 1 | 17.0-19.0 | 9.0-12.0 | 10C -1.10 | ^ |

Specifications :

| DN | NPS(Inch) | D(mm) | SCH5S | SCH10S | SCH40S | STD | SCH40 | SCH80 | XS | SCH80S | SCH160 | XXS |

| 6 | 1/8 | 10.30 | - | 1.24 | 1.73 | 1.73 | 1.73 | 2.41 | 2.41 | 2.41 | - | - |

| 8 | 1/4 | 13.70 | - | 1.65 | 2.24 | 2.24 | 2.24 | 3.02 | 3.02 | 3.02 | - | - |

| 10 | 3/8 | 17.10 | - | 1.65 | 2.31 | 2.31 | 2.31 | 3.20 | 3.20 | 3.20 | - | - |

| 15 | 1/2 | 21.30 | 1.65 | 2.11 | 2.77 | 2.77 | 2.77 | 3.73 | 3.73 | 3.73 | 4.78 | 7.47 |

| 20 | 3/4 | 26.70 | 1.65 | 2.11 | 2.87 | 2.87 | 2.87 | 3.91 | 3.91 | 3.91 | 5.56 | 7.82 |

| 25 | 1 | 33.40 | 1.65 | 2.77 | 3.38 | 3.38 | 3.38 | 4.55 | 4.55 | 4.55 | 6.35 | 9.09 |

| 32 | 1 1/4 | 42.20 | 1.65 | 2.77 | 3.56 | 3.56 | 3.56 | 4.85 | 4.85 | 4.85 | 6.35 | 9.70 |

| 40 | 1 1/2 | 48.30 | 1.65 | 2.77 | 3.68 | 3.68 | 3.68 | 5.08 | 5.08 | 5.08 | 7.14 | 10.15 |

| 50 | 2 | 60.30 | 1.65 | 2.77 | 3.91 | 3.91 | 3.91 | 5.54 | 5.54 | 5.54 | 8.74 | 11.07 |

| Item | Description | |

| Material Grade | TP304 , TP304L , TP304H , TP316 , TP316L , TP316Ti , TP309S , TP310S , TP321 , TP321H , TP347 , TP347H , S31803 , S32750 , S32205 etc | |

| Outer Diameter | 3.18-101.6mm | |

| Wall Thickness | 0.5-20mm | |

| Length | Normally fixed length 6m , can as per customer's requirement | |

| Standard | ASTM A213 ; ASTM A269 ; ASTM A312 ; ASTM A789 ; ASTM A790 ect . | |

| Process Method | Cold Drawn or Cold Rolled | |

| Application | a) For fluid & gas transport | |

| b) Structure & machining | ||

| c) Petrochemical | ||

| d) Environmental protection | ||

| e) Electricity | ||

| f) Instrument industry etc | ||

| Advantages | a) Superior surface finish | |

| b) Better mechanical property | ||

| c) More precise dimension | ||

| d) Perfect inspection method and inspection equipment |

VIP SERVICE

VR (Virtual) Mill Introduction

Professional Remote Technical Guidanceion

Accept Third-party Inspection

Door to Door Shipment

Get QuoteRelated Products: Seamless Tube: Bright Annealed Polished Tube

ASTM A213 S30400 / 30403 Small Diameter Stainless Steel Seamless Tube For Instrument

MTSCO instrument products are made with high quality raw material. Advanced manufacture equipments and the exquisite craft, technology, characteristic of high precise size, good quality surface, stable performace, especially for the reliable durable performance under high temperature. It is widely a......

Bright Annealed Stainless Steel Seamless Hydraulic Tube, ASTM A213 TP316L

We are professional manufacturer of stainless steel pipe, seamless stainless steel pipe. 01) Commodity name: seamless stainless steel pipe 02) Process method: cold rolled/cold drawn 03) Surface finish: annealed/pickling(AP), Bright Annealed(BA) 04) Material: TP304, TP304L,TP304/304L, TP310/S, ......

ASTM B622 / ASME SB622 Alloy 230 / UNS N06230 Nickel Alloy Seamless Tube

1 . Our company has been dedicated to producing nickel alloy tube since 2003 , owning complete producing technology and abundant managing experience . 2 . We have advanced NDT equipments for the tests such as Eddy Current test , Ultrasonic test , Hydraulic test and so on . 3 . We have ISO 9001......

English

English 中 文

中 文 Español

Español Português

Português Deutsch

Deutsch Türk

Türk Pусский

Pусский عربي

عربي 한국인

한국인 日本語

日本語