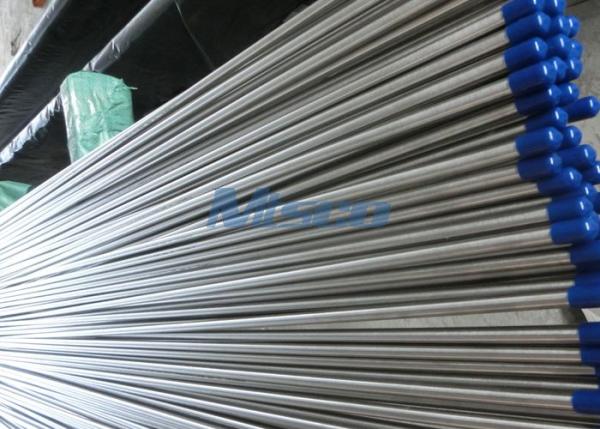

ASTM A269 1/4 Inch Stainless Steel Sanitary Tube For Chemical Industry

SSBA18

Price: From $6000-12000USD/TON

Material: 304, 1.4301, X5CrNi18-10; 304H, S30415, 1.4948, S30409; 304L, 1.4306, S30403, 1.4307; 316L, 1.4401, 1.4404, 1.4435; 316Ti, S31615, 1.4571, S31635;

Get Quote

Sanitary Tubing, Food-Grade Stainless Steel Sanitary Tubing and Piping

Industrial sanitary tubings are widely used in pharmaceutical, food, electronics and other industries that require a clean environment to ensure product hygiene and safety.

Industrial sanitary tubing has very high material requirements, and most of them are made of stainless steel. Stainless steel has good corrosion resistance, not easy to produce chemical reaction, the fluid inside the tubing can remain stable. Moreover, stainless steel is easy to clean and can effectively prevent the growth of bacteria and pollutants. Stainless steel's high strength, abrasion resistance and long service life make it an ideal material for manufacturing sanitary and clean tubings. The polished surface of these materials creates excellent cleanliness, preventing the growth of bacteria and the accumulation of contaminants. At the same time, high quality sanitary tubing is corrosion-resistant and can be used for long-term contact with corrosive pharmaceuticals and foodstuffs. The inner surface is polished so that fluid flows smoothly and does not accumulate.

Sanitary tubing joints also adopt high standard requirements, flange joints, rounded corrugated ends and other designs to avoid dead ends, easy to clean and disinfect. No gaps are allowed between the tubing fittings and flanges. In addition, squeeze joints are eliminated to reduce the risk of contamination.

1 / 4 Inch Stainless Steel Sanitary Tube, ASTM A269 / ASME SA269 For Chemical Industry

Grade

| TP 304; TP304H; TP304L; TP316; TP316L; TP 321;TP321H; TP317L; TP310S; TP347H |

Standard

| ASTM A213, ASTM A 269, ASTM A 270,EN10216-5; ASTM B 622;ASTM B516;ASTM A789, etc |

| Size | OD:3.18-101.6mm |

| WT:0.5-20mm | |

| Length:Max.12M | |

| Advantage | Superior surface finish ,better mechanical property; more precise dimension; perfect inspection method and inspection equipment |

| Application | Boiler tube applies to petroleum,chemical industry,electric power,boiler,high temperature resistant,low temperature resistant,corrosion resistant.The size can be made according to the customers requirements.High pressure boiler pipe applies to container,petrochemical and so on. Note:Generally,high pressure boiler pipe's working pressure above 9.88Mpa and working temperature between 450 to 650. |

| Package | Plastic in both ends, then packed in iron case |

Application :

1 . General service industries ( petroleum , food , chemical , paper , fertilizer , fabric , aviation and nuclear )

2 . Fluid , gas and oil transport

3 . Pressure and heat transmission

4 . Construction and ornament

5 . Boiler and heat exchangers

6 . Decorative usage ( road lamp facilities , bridge handrail , expressway railing , bus stop , airport and gymnasium )

| Terms & Conditions | Price Item | FOB , CFR , CIF or as negotiation |

| Payment | TT, LC or as negotiation | |

| Delivery Time | 30 working days after received your deposit ( Normally according to the order quantity ) | |

| Package | Iron case ; woven bag or as per customer’s requirement | |

| Quality Requirement | Mill Test Certificate will be supplied with shipment , Third Part Inspection is acceptable | |

| Quality | Test | NTD ( Ultrasonic test , Eddy Current test ) |

| Mechanical Test ( Tension Test , Flaring Test , Flattening Test , Hardness Test , Hydraulic test ) | ||

| Metal Test ( Metallographic Analysis , Impact Test - High / low temperature ) | ||

| Chemical Analysis ( Photoelectric Emission Spectroscopic ) | ||

| Market | Main Market | Europe , Middle East , Southeast Asia , South America etc |

ASTM A269 Chemical Composition :

| Elements | 304L(wt%) S30403 | 304(wt%) S30400 | 316L (wt%) S31603 | 316 (wt%) S31600 |

| (C) Carbon, max | 0.035 | 0.08 | 0.035 | 0.08 |

| (Mn) Manganese, max | 2 | 2 | 2 | 2 |

| (P) Phosphorus, max | 0.045 | 0.045 | 0.045 | 0.045 |

| (S) Sulfur, max | 0.03 | 0.03 | 0.03 | 0.03 |

| (Si) Silicon, max | 1 | 1 | 1 | 1 |

| (Ni) Nickel | 8.0 - 12.0 | 8.0 - 11.0 | 10.0 - 14.0 | 10.0 - 14.0 |

| (Cr) Chromium | 18.0 - 20.0 | 18.0 - 20.0 | 16.0 - 18.0 | 16.0 - 18.0 |

| (Mo) Molybdenum | N/A | N/A | 2.0 - 3.0 | 2.0 - 3.0 |

| (Fe) Iron | Bal. | Bal. | Bal. | Bal. |

| (Cu) Copper | N/A | N/A | N/A | N/A |

| (N) Nitrogen | N/A | N/A | N/A | N/A |

VIP SERVICE

VR (Virtual) Mill Introduction

Professional Remote Technical Guidanceion

Accept Third-party Inspection

Door to Door Shipment

Get QuoteRelated Products: Seamless Tube: Annealed Pickled Polished Tube

ASTM A269 / ASME SA269 1.4306 / 1.4404 Stainless Steel Sanitary Tube With Cold Rolled

Bright annealed sanitary tube has very clean inner surface . MTSCO has our own high technology , when tubes have been produced they already have cleaned inner surface , even though we haven’t cleaned them . Of cause , we’ll do clean later . So when we finished clean process , the tubes are totally......

S31600 / S31603 Stainless Steel Precision Seamless Tube With Bright Annealed Surface

Grade: TP 304; TP304H; TP304L; TP316; TP316L; TP 321;TP321H; TP317L; TP310S; TP347H Standard:ASTM A213, ASTM A 269, ASTM A 270,EN10216-5; ASTM B 622;ASTM B516;ASTM A789, etc Size OD:3.18-101.6mm WT:0.5-20mm Length:Max.12M Advantage: Superior surface finish ,better mechanical property; m......

ASTM A213 / A269 TP309S / 310S Stainless Steel Seamless Instrument Tube With Cold Rolled

MTSCO instrument products are made with high quality raw material. Advanced manufacture equipments and the exquisite craft, technology, characteristic of high precise size, good quality surface, stable performace, especially for the reliable durable performance under high temperature. It is widely a......

English

English 中 文

中 文 Español

Español Português

Português Deutsch

Deutsch Türk

Türk Pусский

Pусский عربي

عربي 한국인

한국인 日本語

日本語